ABS-ESC performance testing device and ABS-ESC performance testing method

A testing device and performance technology, which is applied in the field of ABS-ESC performance testing devices, can solve the problems of affecting test accuracy, low system test accuracy, and inability to test, etc., to reduce test differences, improve test accuracy, and improve system test accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

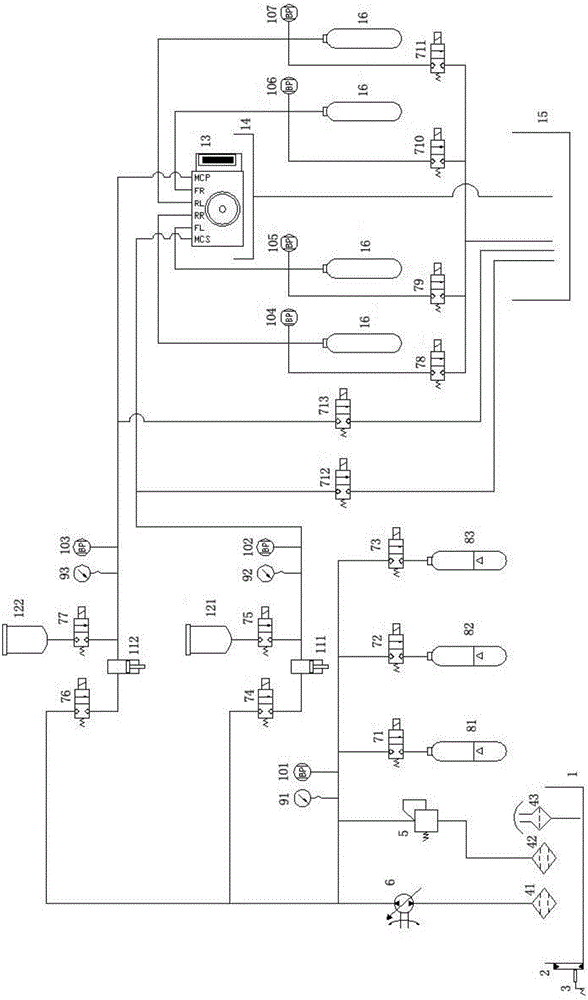

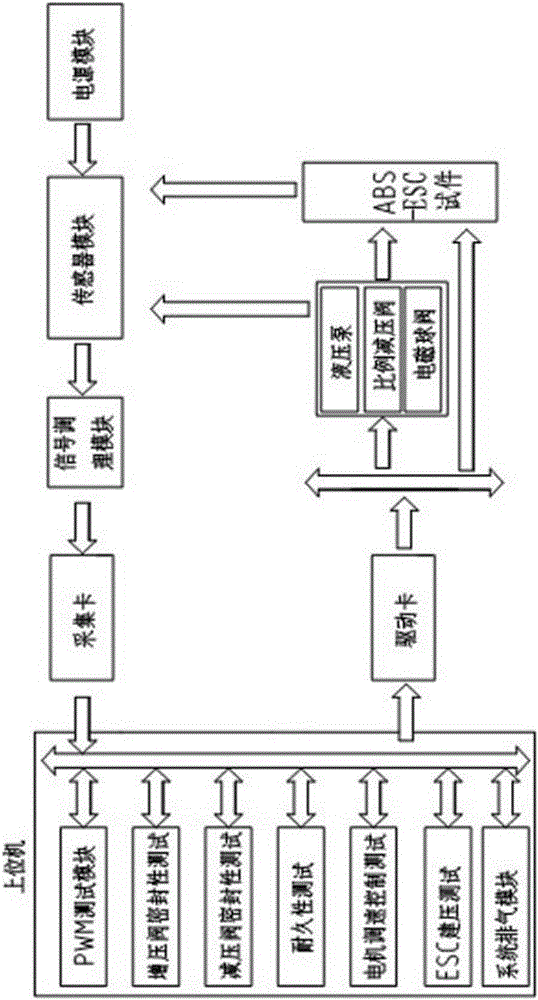

[0060] The ABS-ESC performance testing device of this embodiment is composed of a mechanical hydraulic mechanism and a measurement and control mechanism.

[0061] Such as figure 1 As shown, the mechanical hydraulic mechanism includes an oil tank 1, three oil filters 41-43, a direct-acting overflow valve 5, a hydraulic pump 6, several electromagnetic ball valves 71-713, a high-pressure accumulator 81, a medium-pressure accumulator 82, Low-pressure accumulator 83, three anti-seismic pressure gauges 91-93, several pressure sensors 101-107, two oil pots 121-122, ABS / ESC test piece 13, oil pan 14, waste oil tank 15 and four small steel cylinders 16.

[0062] The three oil filters are installed in the oil tank 1 respectively, the second oil filter 42 is connected to the high-pressure accumulator 81 through the direct-acting overflow valve 5 and the first electromagnetic ball valve 71 in sequence, and the second oil filter 42 is sequentially passed through the direct-acting overflow...

Embodiment 2

[0108] The ABS-ESC performance testing device of the present embodiment is similar to Embodiment 1, and its difference is only in:

[0109] 1. It also includes volume regulating valves 111-112. The pipeline connecting the first oil filter 41 and the second oil filter 42 with the fifth electromagnetic ball valve 75 is also provided with a fourth electromagnetic ball valve 74 and a first volume regulating valve 111 in sequence; The pipeline connecting the first oil filter 41 and the second oil filter 42 with the seventh electromagnetic ball valve 77 is further provided with a sixth electromagnetic ball valve 76 and a second volume regulating valve 112 in sequence. The volume regulating valve can be used to adjust the effective volumes of the MCS loop and the MCP loop, so that the effective volumes of the two loops are the same, and the difference between the two loops can be reduced.

[0110] 2. The oil tank 1 is provided with a liquid level switch 3 and a liquid level gauge 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com