A simple method for measuring the bulkiness of bag-type down

A measurement method and technology of bulkiness, which is applied in the field of down performance testing, can solve the problems of expensive testing equipment, large amount of down consumption, inconvenient carrying, etc., and achieve the effect of simple method, convenient carrying, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment measures down bulkiness according to the following steps:

[0027] (1) Sample processing

[0028] Put 5.0g of 1# down sample to be tested in an oven, and dry it at 70°C for 45 minutes; then shake the down sample to be tested into the pre-treatment box to make it fluffy, and then dry it at a temperature of 70°C and a relative humidity of 65°C. 24h recovery in % of the environment;

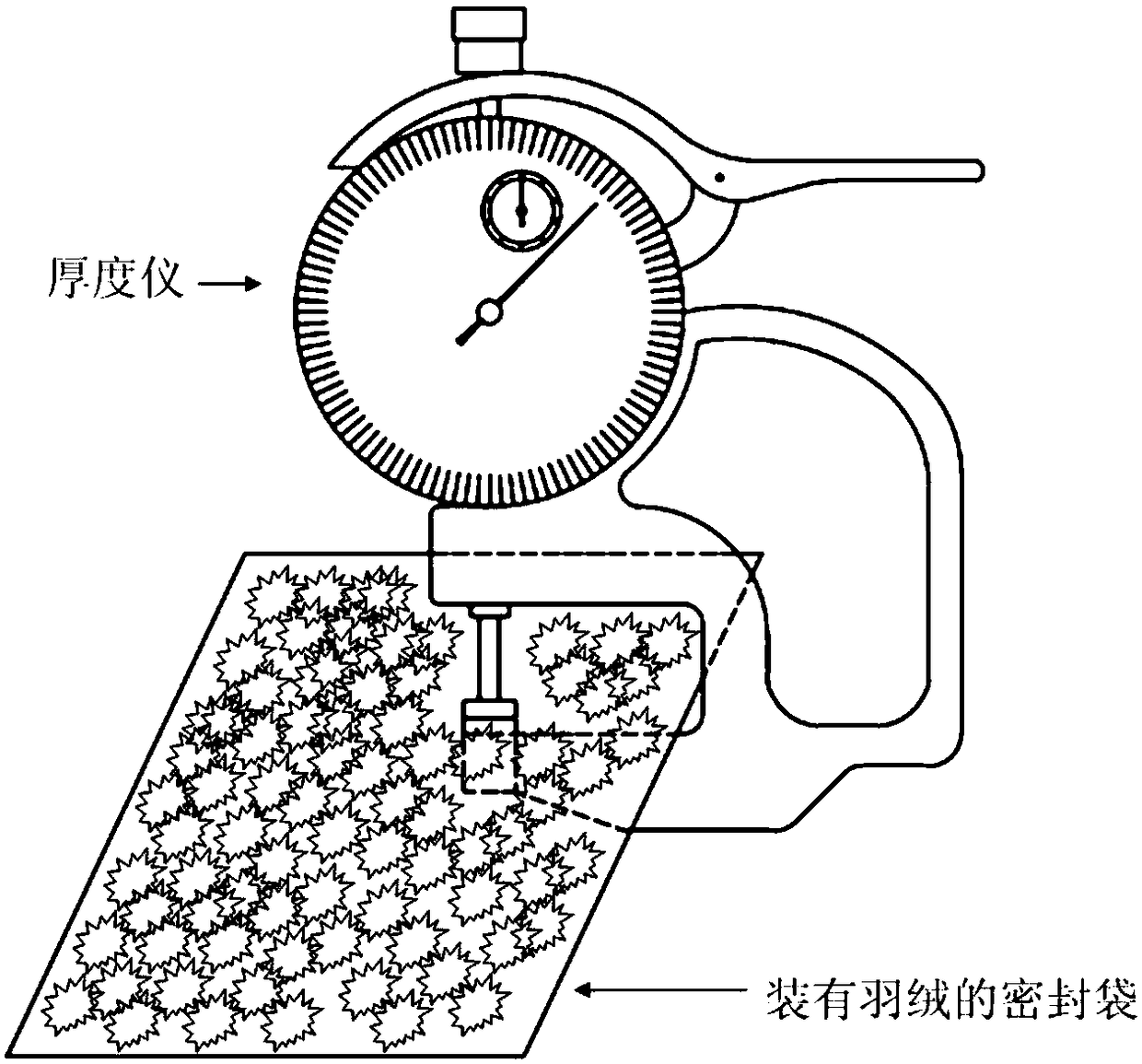

[0029] (2) Thickness measurement

[0030] Spread 1.0g of the treated down sample to be tested evenly in a ziplock bag with a size of 8cm×12cm, exhaust the air in the bag, and seal the bag mouth; randomly select 6 positions on the ziplock bag, and use a thickness meter to measure the thickness of each selected area. The thickness at this time (respectively 1.11cm, 1.00cm, 1.13cm, 1.18cm, 1.19cm, 1.17cm), and then calculate the average value of the thickness of the 6 places is 1.13cm, as the minimum thickness T of the down to be tested 0 ;

[0031] Let the ziplock bag...

Embodiment 2

[0036] The present embodiment measures down bulkiness according to the following steps:

[0037] (1) Sample processing

[0038] Put 5.0g of the 2# down sample to be tested in an oven, and dry it at 70°C for 45 minutes; then shake the down sample to be tested into the pre-treatment box to make it fluffy, and then dry it at a temperature of 70°C and a relative humidity of 65°C. 24h recovery in % of the environment;

[0039] (2) Thickness measurement

[0040] Spread 1.0g of the treated down sample to be tested evenly in a ziplock bag with a size of 8cm×12cm, exhaust the air in the bag, and seal the bag mouth; randomly select 6 positions on the ziplock bag, and use a thickness meter to measure the thickness of each selected area. The thickness at this time (respectively 1.31cm, 1.37cm, 1.24cm, 1.28cm, 1.26cm, 1.25cm), and then calculate the average value of 1.29cm of the thickness of the 6 places, as the minimum thickness T of the down to be tested 0 ;

[0041] Leave the ziplo...

Embodiment 3

[0046] The present embodiment measures down bulkiness according to the following steps:

[0047] (1) Sample processing

[0048] Put 5.0g of 3# down sample to be tested in an oven, and dry it at 70°C for 45 minutes; then shake the down sample to be tested into the pre-treatment box to make it fluffy, and then dry it at a temperature of 70°C and a relative humidity of 65°C. 24h recovery in % of the environment;

[0049] (2) Thickness measurement

[0050] Spread 1.0g of the treated down sample to be tested evenly in a ziplock bag with a size of 8cm×12cm, exhaust the air in the bag, and seal the bag mouth; randomly select 6 positions on the ziplock bag, and use a thickness meter to measure the thickness of each selected area. The thickness at this time (respectively 1.09cm, 1.07cm, 1.04cm, 1.08cm, 1.07cm, 1.01cm), and then calculate the average value of 1.06cm of the thickness of the 6 places, as the minimum thickness T of the down to be tested 0 ;

[0051]Leave the ziplock ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com