Electric connection method for secondary arc prevention

A secondary arc and electrical connection technology, applied in the direction of conductive adhesive connection, contact parts, base/housing, etc., can solve the problems of low service life, damage to electrical contact ends, etc., and achieve separation or falling off, good promotion, design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

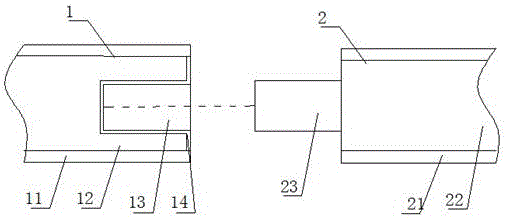

[0027] Such as figure 1 As shown, the electrical connector for preventing secondary arc of the present invention includes a first connecting end 1 and a second connecting end 2 .

[0028] The first connection end 1 includes a first insulating layer 11 and a first conductor 12. The first insulating layer 11 is wrapped around the outside of the first conductor 12. The connection side of the first conductor 12 is provided with a connection groove 13, which has a fluid conductive medium layer. 14 sets the inner surface of the connection groove 13.

[0029] The second connecting end 2 includes a second insulating layer 21 and a second conductor 22 , the second insulating layer 21 is wrapped around the second conductor 22 , and the connecting side of the second conductor 22 is provided with a connecting portion 23 matching the connecting groove 13 .

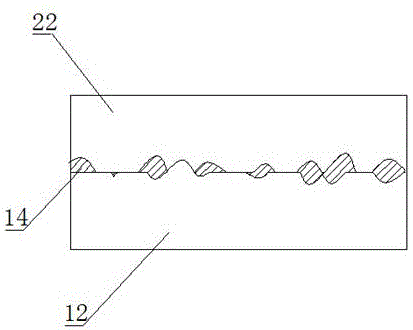

[0030] Such as image 3 , 4 As shown, during the electrical connection process between the first connecting end 1 and the second c...

Embodiment 2

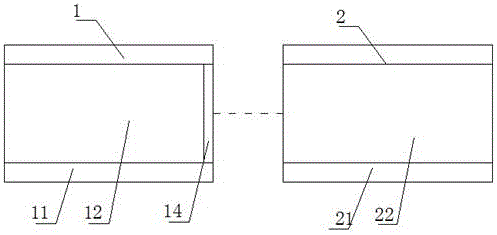

[0032] Such as figure 2 As shown, the electrical connector for preventing secondary arc of the present invention includes a first connecting end 1 and a second connecting end 2 .

[0033] The first connecting end 1 includes a first insulating layer 11 and a first conductor 12, and the second connecting end 2 includes a second insulating layer 21 and a second conductor 22; the electrical contact surface on the front side of the first conductor 12 is provided with a conductive medium layer 14. The conductive medium layer 14 has fluidity.

[0034] Such as image 3 , 5 As shown, when the first connection end 1 and the second connection end 2 are electrically connected, the first conductor 12 and the second conductor 22 approach each other at a certain speed, and due to the kinetic energy difference between the first conductor 12 and the second conductor 22, After the first conductor 12 and the second conductor 22 collide and conduct electricity for the first time, the gap gen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap