Portable wire aluminum armor tape winding device for overhead line of electric power grid

A technology of overhead lines and winding devices, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inability to guarantee the quality and efficiency of work completion, boring work, and high labor intensity, so as to increase the workload of work, be easy to carry, and improve work efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing.

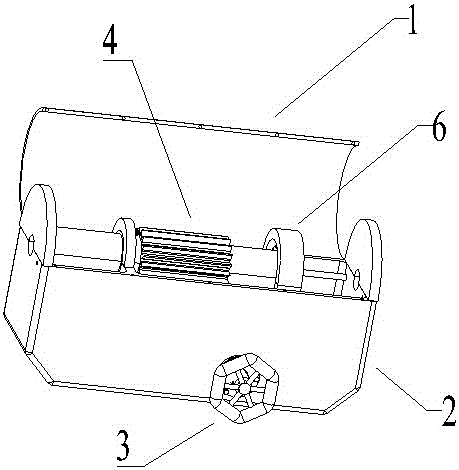

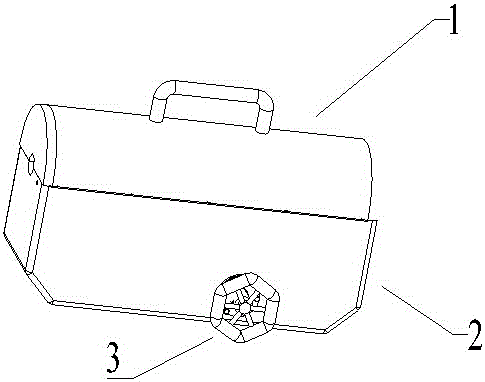

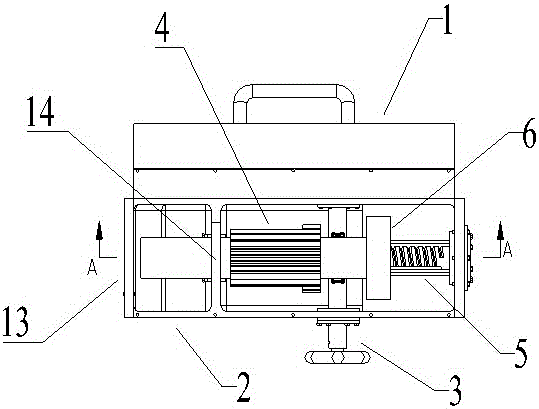

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 , Image 6 with Figure 14 As shown, the portable aluminum-clad tape winding device for electric power grid overhead lines disclosed by the present invention includes a case cover 1, a case body 2, a power device 3, a gear guide sleeve 4, a transmission device 5, a sliding bearing seat 6 and a winding device 7.

[0056] Such as Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the box cover 1 is fixedly connected with the box body 2 and is arranged correspondingly. The box cover 1 includes a box cover body 11, a snap protrusion 12, a wire fixing clip 13 and a gear guide sleeve upper clip 14, and the button protrusion 12 is fixed. Set on the box cover body 11, the box cover body 11 is set corresponding to the box body 2, the wire fixing clip 13 and the gear guide sleeve upper clip 14 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com