Switched reluctance motor of rechargeable ship and switched reluctance drive device

A switched reluctance motor and switched reluctance drive technology, applied in electromechanical devices, electrical components, etc., can solve problems such as torque ripple, unreliability, and potential safety hazards, reduce unilateral deformation, and increase quasi-salient poles Quantity, the effect of reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

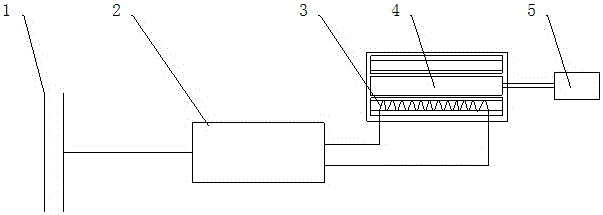

[0020] See Figure 1-Figure 5 , The present invention provides a technical solution: a switched reluctance motor and a switched reluctance drive device for a charging ship, including a ship power grid 1, a voltage converter 2, a phase winding 3, a switched reluctance motor 4 and a load 5, and a ship power grid 1 The left end of the voltage converter 2 is connected by a wire, and the right end of the voltage converter 2 is connected with the phase winding 3 by a wire. The phase winding 3 is installed in the switched reluctance motor 4, and the right end of the switched reluctance motor 4 is equipped with a load 5.

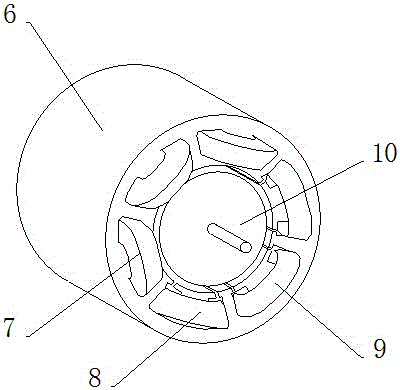

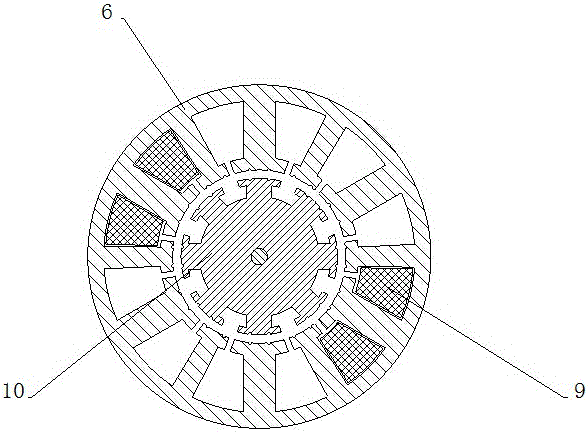

[0021] The structure of switched reluctance motor 4 is composed of stator mechanism 6, A phase coil 7, B phase coil 8, C phase coil 9 and rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com