a tethered connector

A connector and mooring technology, which is applied to aircraft, aircraft lighter than air, motor vehicles, etc., can solve the problems of small breaking force index, large weight index of large-tonnage tethered connector, and large discreteness of tensile force index, etc. Achieve the effect of improving work reliability, improving work breaking tension index, and avoiding vibration and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation process of the present invention will be further described in detail below in conjunction with each accompanying drawing.

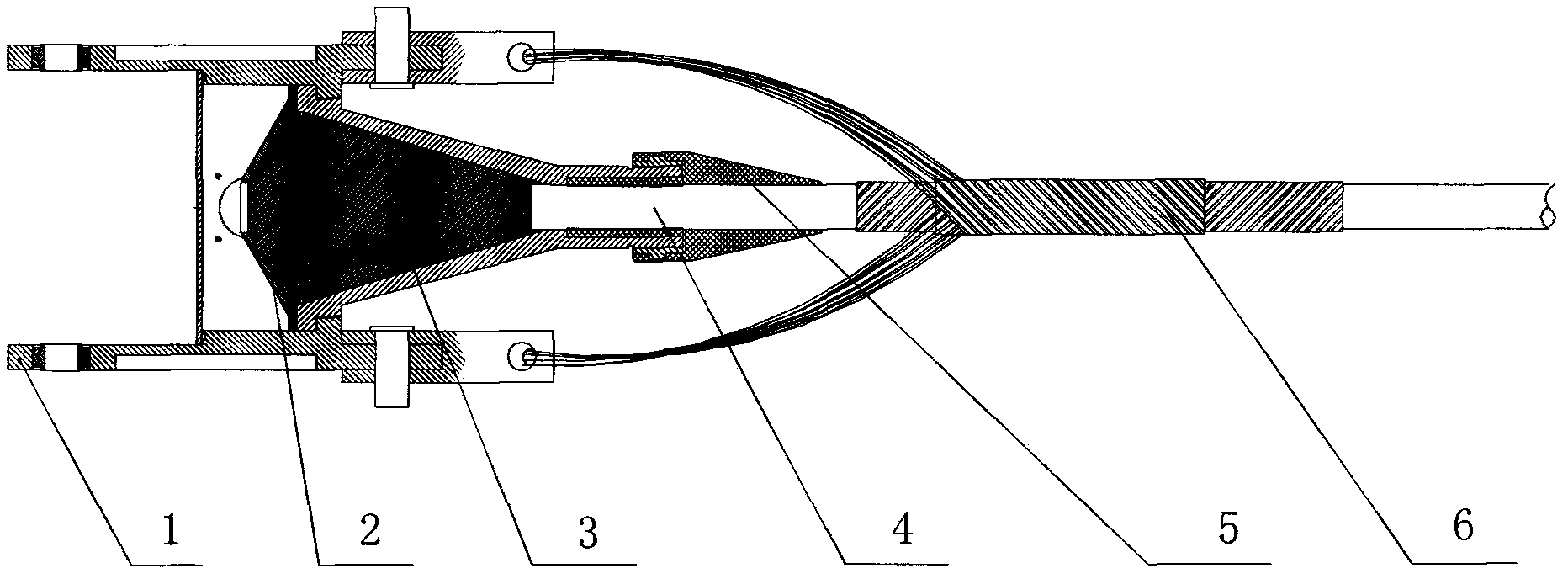

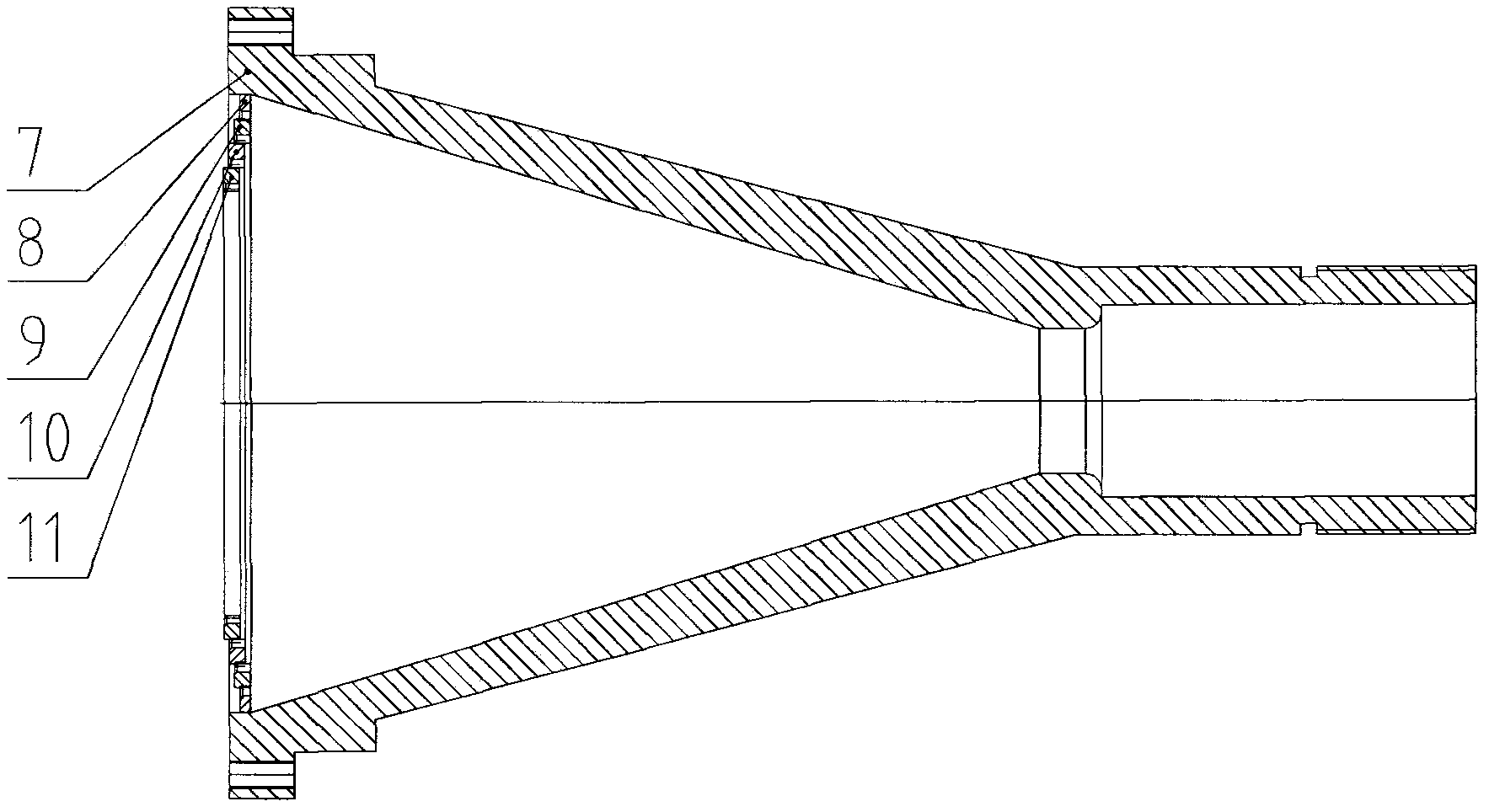

[0032] see figure 1 , which is a structural schematic diagram of the tethered connector of the present invention, which mainly includes a lower hinge 1, a fixed sleeve 2, a load-bearing mechanism 3, a tethered cable 4, a rubber boot 5 and a wire shock absorber 6. Wherein, one end of the lower hinge 1 is connected to the aerostat, and the other end is connected to the load-bearing mechanism 3 through bolts, which serves as a transitional connection with the rope on the aerostat. The load-bearing mechanism 3 and the mooring cable 4 are bonded together by epoxy resin, which is used to fix the non-metallic reinforcing fiber in the mooring cable 4, so that the mooring connector has a large working breaking force. The load-bearing mechanism 3 and the fixed sleeve 2 are connected together by bolts. There is an opening on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com