Large-diameter high-precision optical glass forming device and its process

An optical glass and molding process technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as poor effect, small molding size, and large heat loss from heating and heat preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

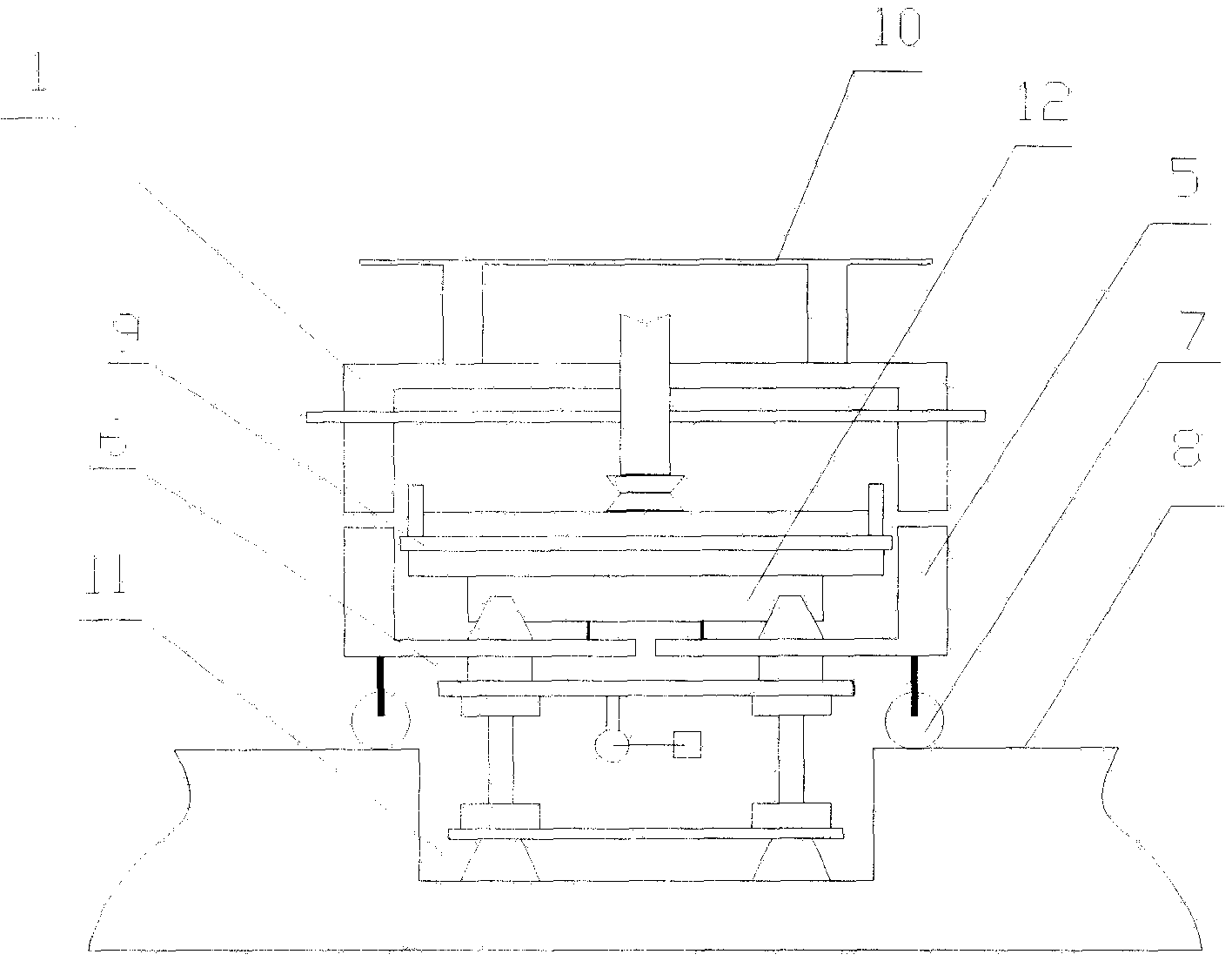

[0011] The present invention adds heat preservation cover 5 in the lower part of forming mold 9, and heat preservation cover 5 and molding furnace 1 arrange the upper and lower parts of forming mold 9, and form a closed cavity, as figure 2 As shown, the device of the present invention is changed to fully enclosed heating and heat preservation, which solves the problems that the molded glass steamed bread has a large surface, the molding time exceeds 5 hours, and the molded glass will burst. When forming glass, the forming elevator 6 needs to move up and down, so the heat preservation cover 5 is set to be composed of left and right parts, and moving wheels 7 are installed respectively, so that the left and right parts of the heat preservation cover 5 can move on the ground 8, so that before the forming starts It will be more convenient for the forming mold 9 to enter the forming device and the glass to move out of the forming device after the forming is completed.

[0012] Abo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap