Zipper

A technology for zippers and zipper tapes, applied in the field of zippers, which can solve the problems of zipper blocks being astringent, sliding parts stuck, and zipper opening and closing not smooth, etc., to achieve the effect of improving the transverse tensile strength and smooth opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

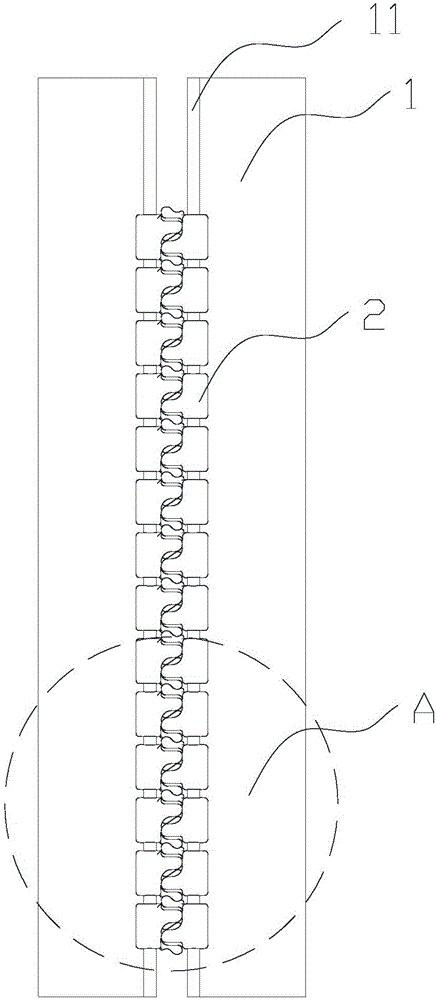

[0028] Such as Figure 1-2 As shown, a zipper includes two zipper tapes 1 and two zipper sets 2 . The edges of the zipper tape 1 are provided with installation ribs 11 , and each zipper group 2 is clipped on one installation rib 11 respectively, and the two zipper groups 2 are fastened together. The installation rib 11 is in a cylindrical shape, which is for the convenience of the installation of the zipper set 2 and also for safety.

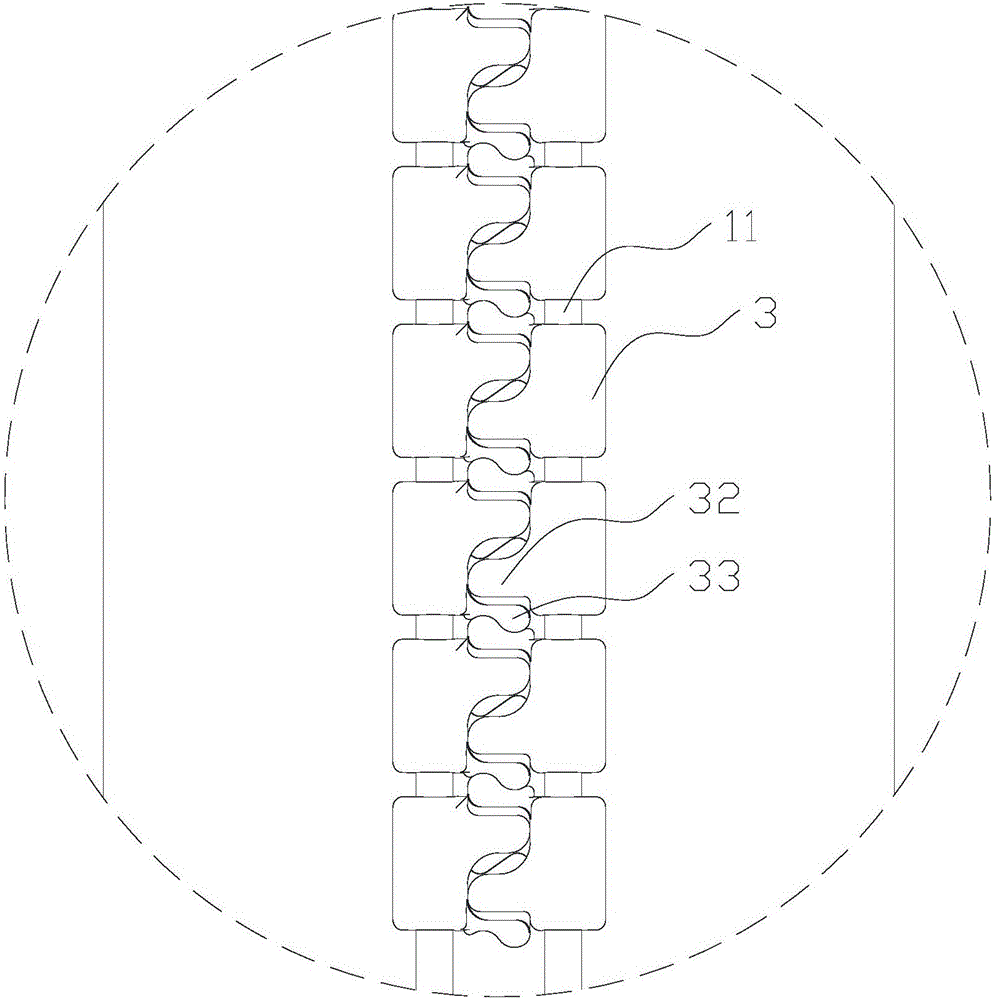

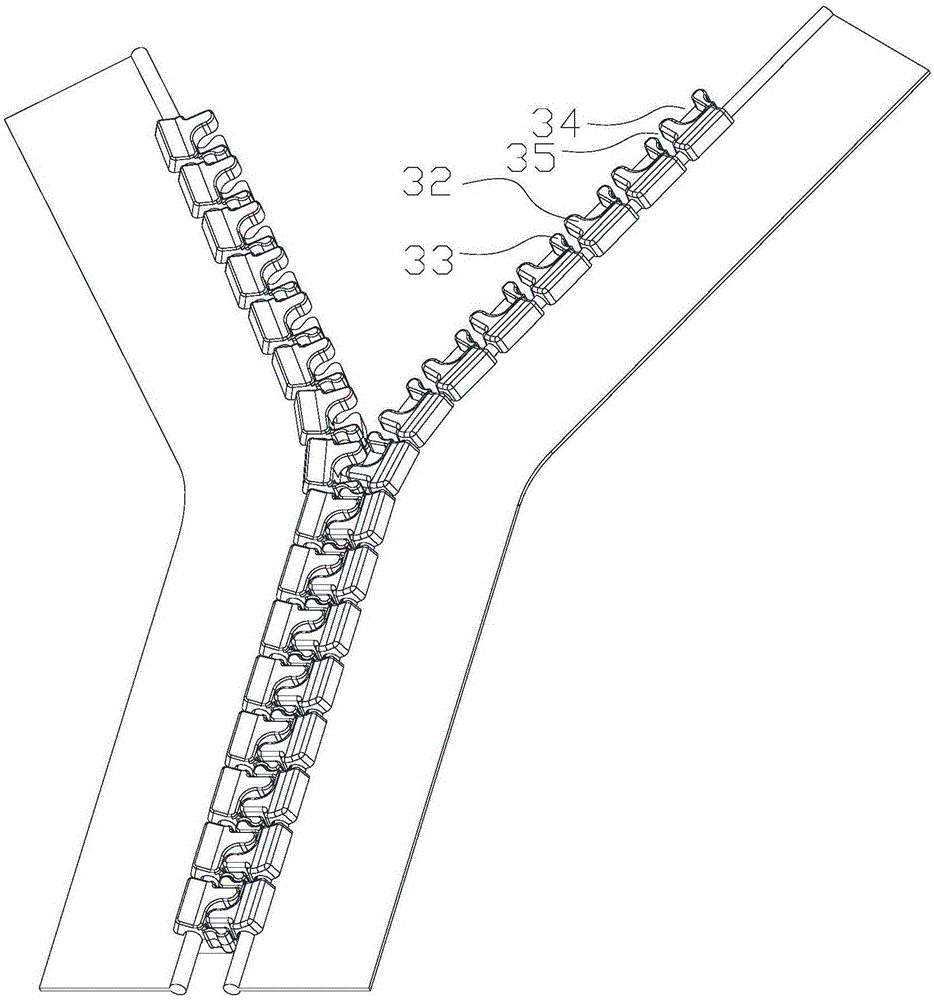

[0029] Such as image 3 As shown, each zipper set 2 includes a plurality of zipper blocks 3 arranged in sequence, the outer side of the zipper block 3 is provided with a mounting groove 31 for inserting on the installation rib 11, and one end of the inner side of the zipper block 3 is provided with a snap tooth 32, the other end is provided with a guide tooth 33; a buckle groove 34 is formed between the buckle tooth 32 and the guide tooth 33 on each zipper block 3 in the same zipper group 2, and is used for fitting on another zipper group 2 T...

Embodiment 2

[0032] Such as Figure 4 , 6 As shown, the fastening teeth 32 and guide teeth 33 on the same zipper block 3 are arranged on the upper layer on the side of the zipper block 3 away from the mounting groove 31, and the lower layer on this side is provided with reinforcing teeth 36, and the reinforcing teeth 36 and the fastening teeth 32. The guide teeth 33 are arranged alternately and misplaced. A reinforcing groove 37 is provided on a side of the reinforcing tooth 36 close to the guide tooth 33 , for snap-fitting the matching reinforcing tooth 36 on another zipper set 2 . The reinforcing tooth 36 is a cube shape, and the reinforcing groove 37 of the reinforcing tooth 36 is a smooth concave surface 371. The setting of the smooth concave surface 371 makes the zipper blocks 3 on the two zipper tapes 1 open and close when the slider is closed or pulled apart. more smoothly.

[0033] Other structures and connection methods are the same as in Embodiment 1.

[0034] The upper layer...

Embodiment 3

[0036] Such as Figure 5 As shown, the side of the fastening teeth 32 on the same zipper block 3 facing the guide teeth 33 is provided with a smooth arc surface 321 which is conducive to fastening; Smooth curved surface 331 for snap fit. The arrangement of the smooth curved surface 321 and the smooth curved surface 331 makes the opening and closing of the zipper blocks 3 on the two zipper tapes 1 more smooth when the sliders are closed or pulled apart.

[0037] The inner side of the curved surface 331 of the guide tooth 33 is provided with an arc-shaped convex portion 332 , and the outer side of the curved surface 331 is provided with an arc-shaped concave portion 333 , and the arc-shaped convex portion 332 and the arc-shaped concave portion 333 are connected smoothly. The setting of the arc-shaped convex portion 332 and the arc-shaped concave portion 333 of the guide tooth 33 is to make the snap connection of the two guide teeth 33 tighter, and the setting of the smooth tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com