Storage rack laminate frame sheet improved structure

A technology of improving structure and shelf, applied in furniture parts, applications, household appliances, etc., can solve the problems of time-consuming processing, easy to be affected by welding marks on appearance, difficult to control quality, etc. Practical value, effect on solving weld marks and related problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

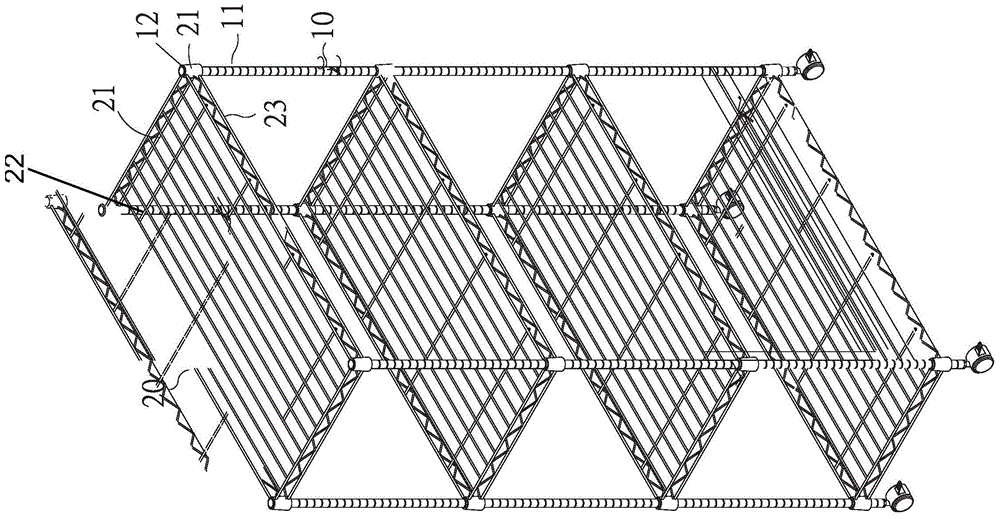

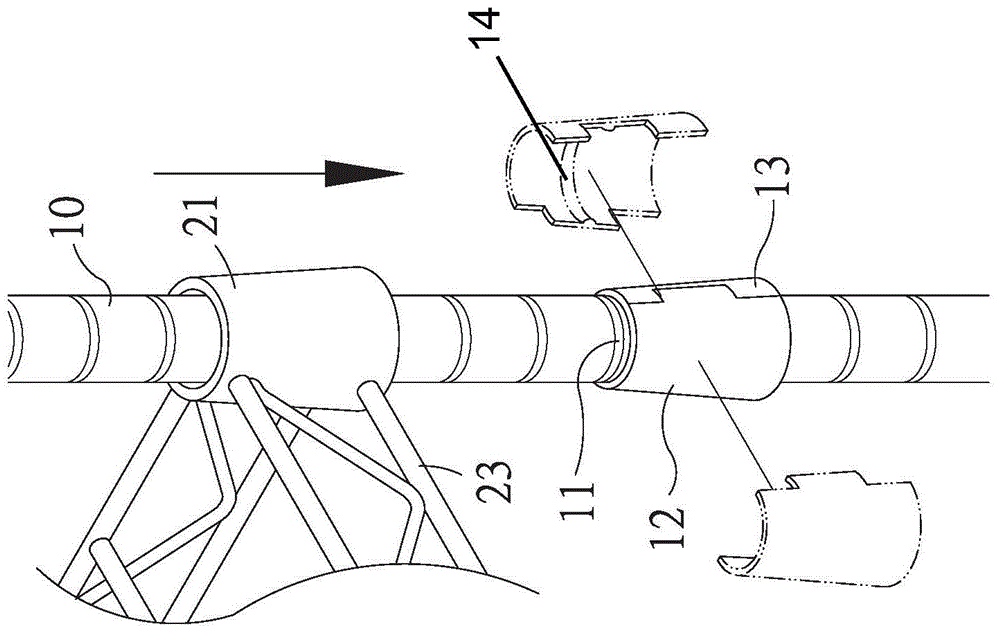

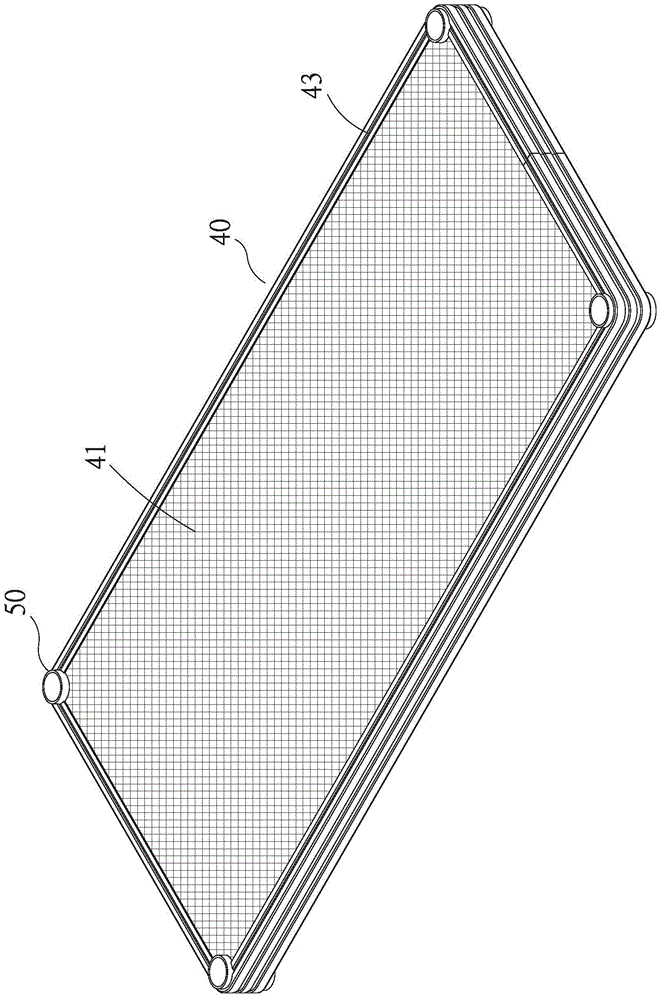

[0028] see Figure 3 to Figure 12 As shown, in the design of the combination structure of the shelf shelf frame and the pipe sleeve of the present invention, it is mainly formed by combining a metal mesh sheet (41) or other types of storage panels and a sheet-type frame (42). The laminate (40) of the storage rack (30), and utilizes the sleeve (50) that the four end corners of the laminate (40) frame sheet (42) are assembled to cooperate with another plastic kit (32) to obtain a cover set. Be arranged on the upright pole column (31) of storage rack (30), complete the overall combination of its storage rack (30), wherein:

[0029] In the combined design of the laminate (40) and the sleeve (50), the upper and lower edges of the frame (42) of the laminate (40) are respectively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com