Pit and fissure sealant based on the concept of tooth surface hydrophobization

A technology of pit and fissure sealing and hydrophobizing agent, which can be used in dental prostheses, dental preparations, dentistry, etc., and can solve the problems of pit and fissure sealing and shedding, interface defects, and easy accumulation of food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

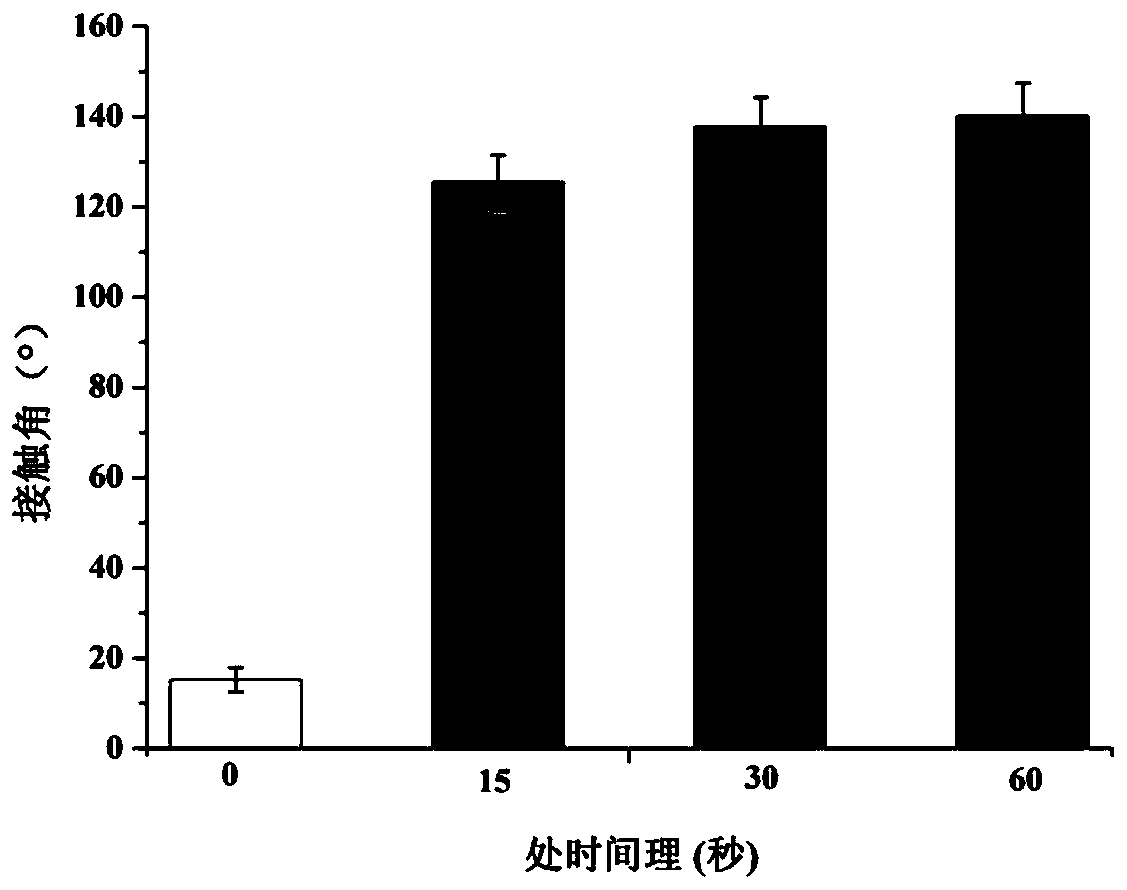

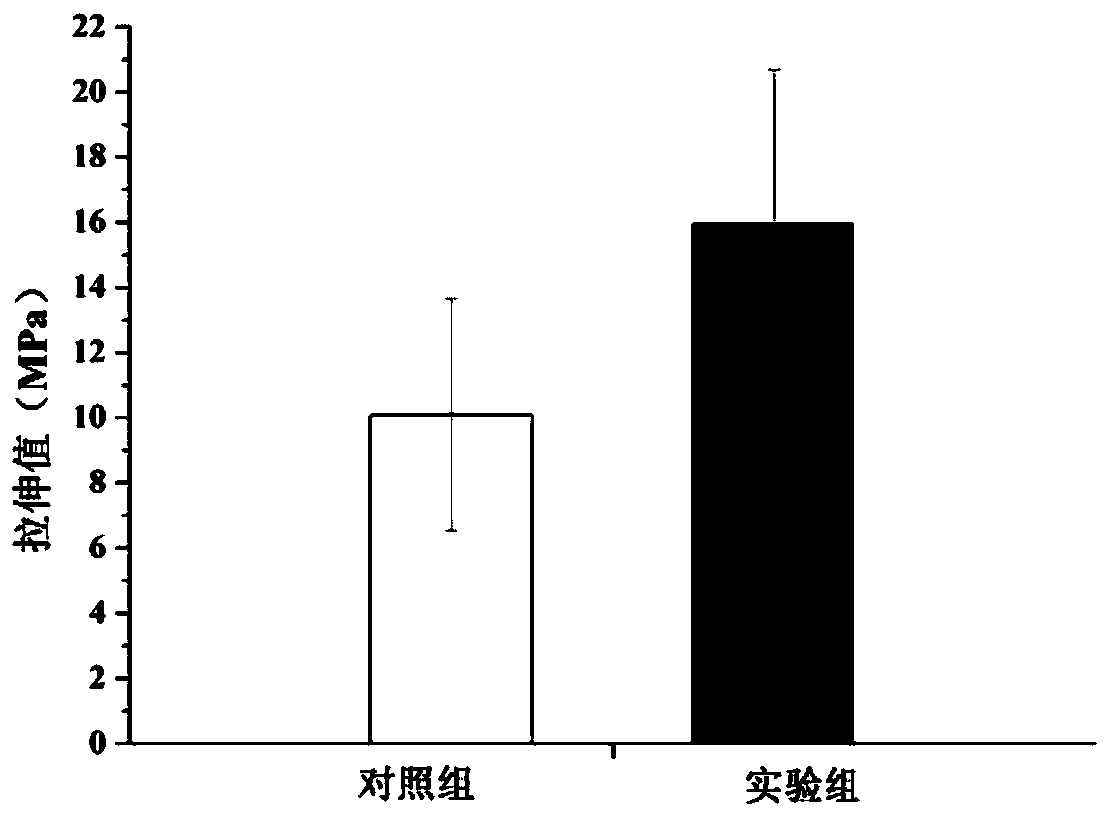

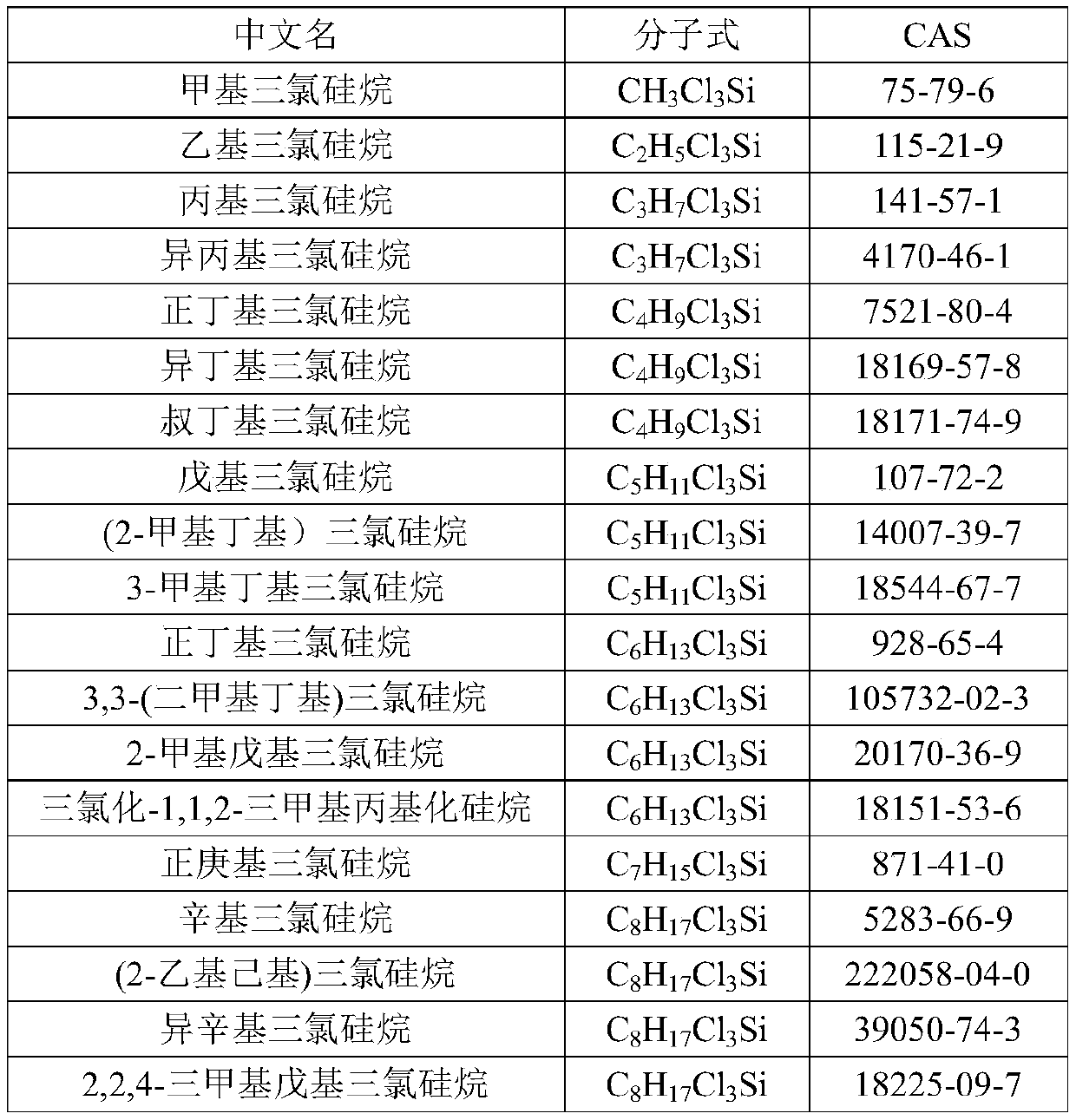

[0025] 1. Component A: 0.1 (V / V)% alkyl trichlorosilane (see attached table 1 for details, taking octadecyl trichlorosilane as an example) ether solution.

[0026] 2. Component B: 20 wt% bisphenol A diglycidyl methacrylate, 40 wt% 10 ethoxylated bisphenol A glycidyl dimethacrylate, 30 wt% 4 ethoxylated bisphenol A glycidyl dimethacrylate , 1wt% camphorquinone, 9wt% silane-treated silica powder, prepared after mixing.

Embodiment 2

[0028] 1. Component A: 1 (V / V)% fluorotrichlorosilane (see attached table 2) ethanol solution.

[0029] 2. Component B: 20 wt% bisphenol A diglycidyl methacrylate, 40 wt% 10 ethoxylated bisphenol A glycidyl dimethacrylate, 30 wt% 4 ethoxylated bisphenol A glycidyl dimethacrylate , 1wt% camphorquinone, 9wt% silane-treated silica powder, prepared after mixing.

Embodiment 3

[0031] 1. Component A: 1 (V / V)% functionalized trichlorosilane (see attached table 3 for details) ethanol solution.

[0032] 2. Component B: 20 wt% bisphenol A diglycidyl methacrylate, 40 wt% 10 ethoxylated bisphenol A glycidyl dimethacrylate, 30 wt% 4 ethoxylated bisphenol A glycidyl dimethacrylate , 1wt% camphorquinone, 9wt% silane-treated silica powder, prepared after mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com