Nano TiO2-modified PEO/PVDF composite ultra-filtration membrane and preparation method thereof

A kind of ultrafiltration membrane and nanotechnology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of weak anti-pollution ability, strong hydrophobicity, low water flux, etc., and achieve improved water purification efficiency and hydrophilic The effect of improving performance and increasing water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

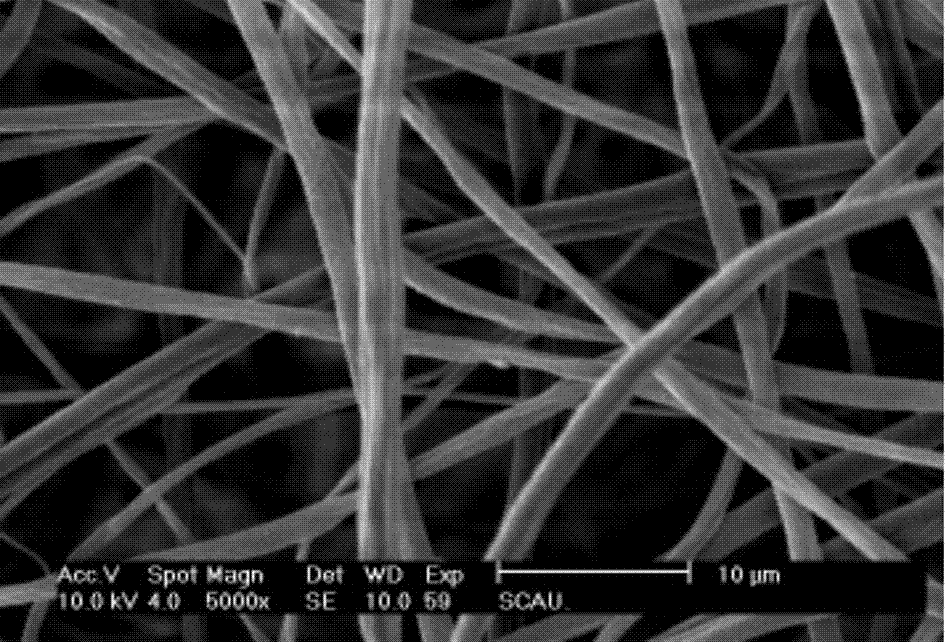

Embodiment 1

[0027] A preparation method of pure PVDF ultrafiltration membrane, comprising the following steps:

[0028] (1) Add 1.0 g of dichloromethane, 5.4 g of acetone, and 3.6 g of N,N-dimethylacetamide into a glass bottle with a lid to make a mixed solvent, then add 1.5 g of PVDF powder, and put Put it into the magnet, cover the lid, put it in a constant temperature water bath magnet stirrer at a constant temperature of 50°C and stir for 2 hours. After stirring, take it out and let it stand for defoaming to obtain pure PVDF spinning solution.

[0029] (2) Take a 10ml syringe, absorb N,N-dimethylacetamide to clean the syringe, and draw more than 5ml of spinning solution, fix the syringe in the electrospinning machine, and spread it on the receiving tray Put a layer of tin foil on it, adjust the voltage to 16KV, spin the spinning rate to 0.5ml / h, and spin the amount to 5ml. Spinning is performed after the parameters are adjusted.

[0030] Before absorbing the above spinning solution...

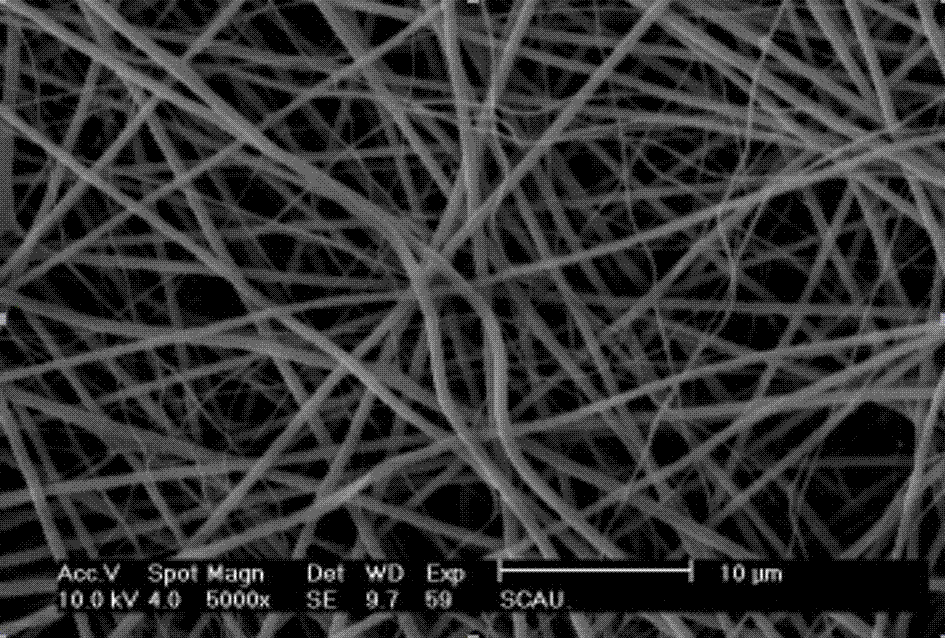

Embodiment 2

[0040] A preparation method of PEO / PVDF composite ultrafiltration membrane, comprising the following steps:

[0041] (1) Add 1.0 g of dichloromethane, 5.4 g of acetone, and 3.6 g of N,N-dimethylacetamide into a glass bottle with a lid to make a mixed solvent, then add 0.02 g of nano-PEO particles, Put in the magnet, cover the lid, put it in a constant temperature water bath magnetic stirrer at a constant temperature of 60°C and stir until the PEO is completely dissolved, then add 1.5g of PVDF powder, continue to put it in a constant temperature water bath magnetic stirrer at a constant temperature of 50°C and stir for 2 Hour. After stirring, take it out and let it stand for swelling for 12 hours to obtain blended spinning solution A. According to the above steps, 0.04g, 0.06g, 0.08g of nano-PEO particles were added respectively, and the amounts and steps of other substances remained unchanged, and the blended spinning solutions B, C, and D could be obtained respectively.

[...

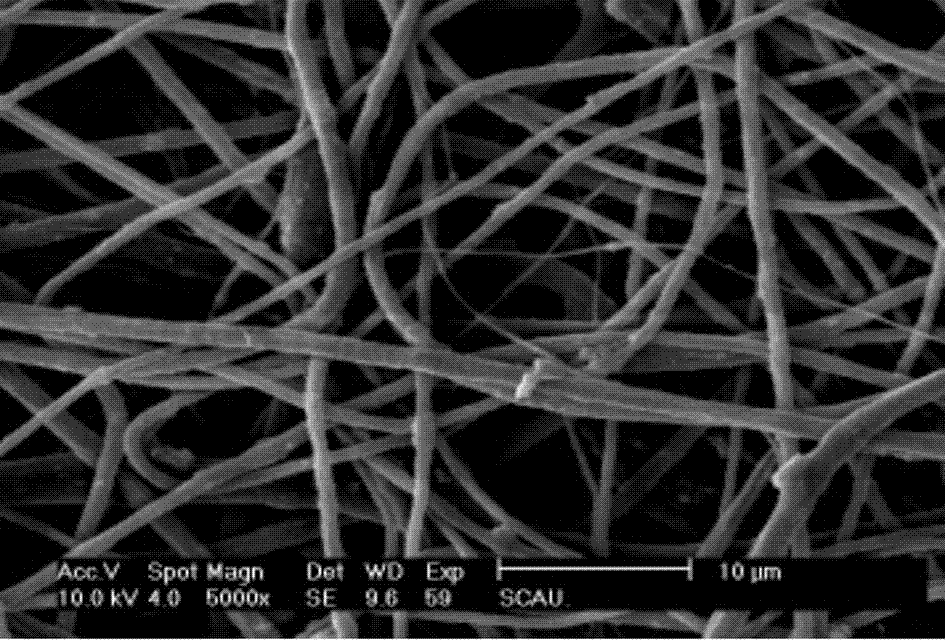

Embodiment 3

[0049] A kind of nano TiO 2 The preparation method of modified PEO / PVDF composite ultrafiltration membrane comprises the following steps:

[0050] (1) Add 1.0 g of dichloromethane, 5.4 g of acetone, and 3.6 g of N,N-dimethylacetamide into a glass bottle with a lid to make a mixed solvent, then add 0.06 g of nano-PEO particles, Put in the magnet, cover the lid, put it in a constant temperature water bath magnetic stirrer at a constant temperature of 60 ℃ and stir until the PEO is completely dissolved, then add 1.5g of PVDF, put it in a constant temperature water bath magnetic stirrer at a constant temperature of 50 ℃ and stir until the PVDF After complete dissolution, add 0.02g nano-TiO 2 The granules were further placed in a constant temperature water bath magnetic stirrer and stirred at a constant temperature of 50° C. for 2 hours. After stirring, take it out and let it stand for swelling for 12 hours to obtain the blended spinning solution E. According to the above steps,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com