Cellulose/tannin micro-nano fibers and preparation method thereof

A cellulose, micro-nano technology, applied in the field of materials, can solve the problems of adding process steps, complicated operations, long preparation routes, etc., and achieves the effects of simple process, reduced production cost, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

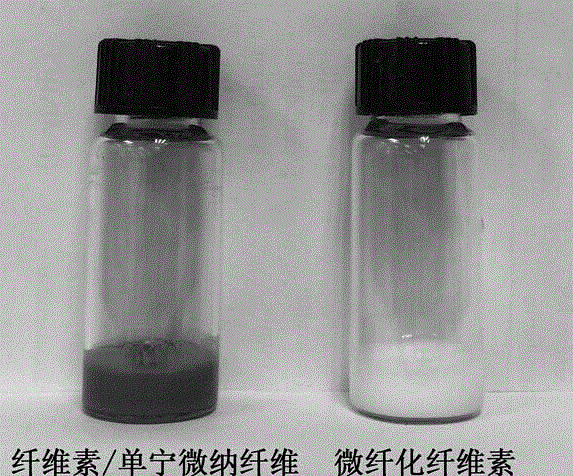

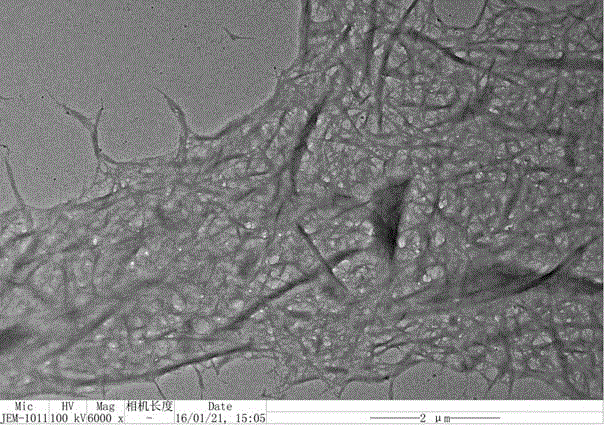

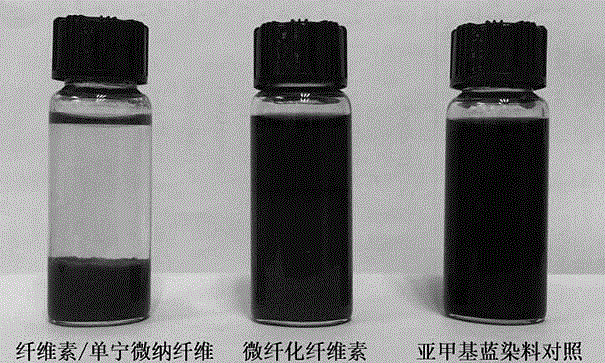

[0023] A cellulose / tannin micro-nano fiber is a product obtained by reacting a mixture of microfibrillated cellulose and tannin aqueous solution with an immobilizing agent (epichlorohydrin). The mass concentration of the tannin aqueous solution is 5wt%, the ratio of the microfibrillated cellulose to the tannin aqueous solution is 1:10 (g:ml), and the volume ratio of the immobilization reagent (epichlorohydrin) to the tannin aqueous solution is 1: 100. The aspect ratio of microfibrillated cellulose is: 1:200~1:600, and the diameter is 15~30nm.

[0024] Its preparation method comprises the following steps:

[0025] (1) Dissolving tannin in distilled water to obtain a tannin aqueous solution with a mass concentration of 5 wt %; the tannin is Vitex bark tannin.

[0026] (2) Add the microfibrillated cellulose into the tannin aqueous solution according to the proportion, and fully stir and disperse evenly to obtain the microfibrillated cellulose-tannin mixture; the microfibrillate...

Embodiment 2

[0030] A cellulose / tannin micro-nano fiber is a product obtained by reacting a mixture of microfibrillated cellulose and tannin aqueous solution with an immobilizing agent (50 wt % glutaraldehyde aqueous solution). The mass concentration of tannin aqueous solution is 15wt%, the ratio of microfibrillated cellulose to tannin aqueous solution is 1:20 (g:ml), the volume ratio of immobilization reagent (50wt% glutaraldehyde aqueous solution) to tannin aqueous solution It is 3:100. The aspect ratio of microfibrillated cellulose is: 1:200~1:600, and the diameter is 15~30nm.

[0031] Its preparation method comprises the following steps:

[0032] (1) Dissolving a certain amount of tannin in distilled water to obtain an aqueous solution of tannin; the tannin is quebracho tannin.

[0033] (2) Add the microfibrillated cellulose to the tannin aqueous solution according to the proportion, and fully stir and disperse evenly to obtain the microfibrillated cellulose-tannin mixture; the micro...

Embodiment 3

[0037] A cellulose / tannin micro-nano fiber is a product obtained by reacting a mixture of microfibrillated cellulose and tannin aqueous solution by adding an immobilizing agent (30wt% citric acid aqueous solution). The mass concentration of the tannin aqueous solution is 15wt%, the ratio of the microfibrillated cellulose to the tannin aqueous solution is 3:10 (g:ml), and the volume ratio of the immobilization reagent (30wt% citric acid aqueous solution) to the tannin aqueous solution is 5:100. The aspect ratio of microfibrillated cellulose is: 1:200~1:600, and the diameter is 15~30nm.

[0038] Its preparation method comprises the following steps:

[0039] (1) Dissolving a certain amount of tannin in distilled water to obtain an aqueous solution of tannin; the tannin is bayberry tannin.

[0040] (2) Adding the microfibrillated cellulose into the tannin aqueous solution according to the proportion, and fully stirring and dispersing evenly to obtain the microfibrillated cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com