System and method for removing foam of desulfurization slurry tank by ultrasonic waves

A desulfurization slurry and ultrasonic technology, applied in separation methods, foam dispersion/prevention, chemical instruments and methods, etc., can solve problems affecting desulfurization efficiency and increase operating costs, so as to promote gas-liquid reaction, avoid corrosion, and improve desulfurization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

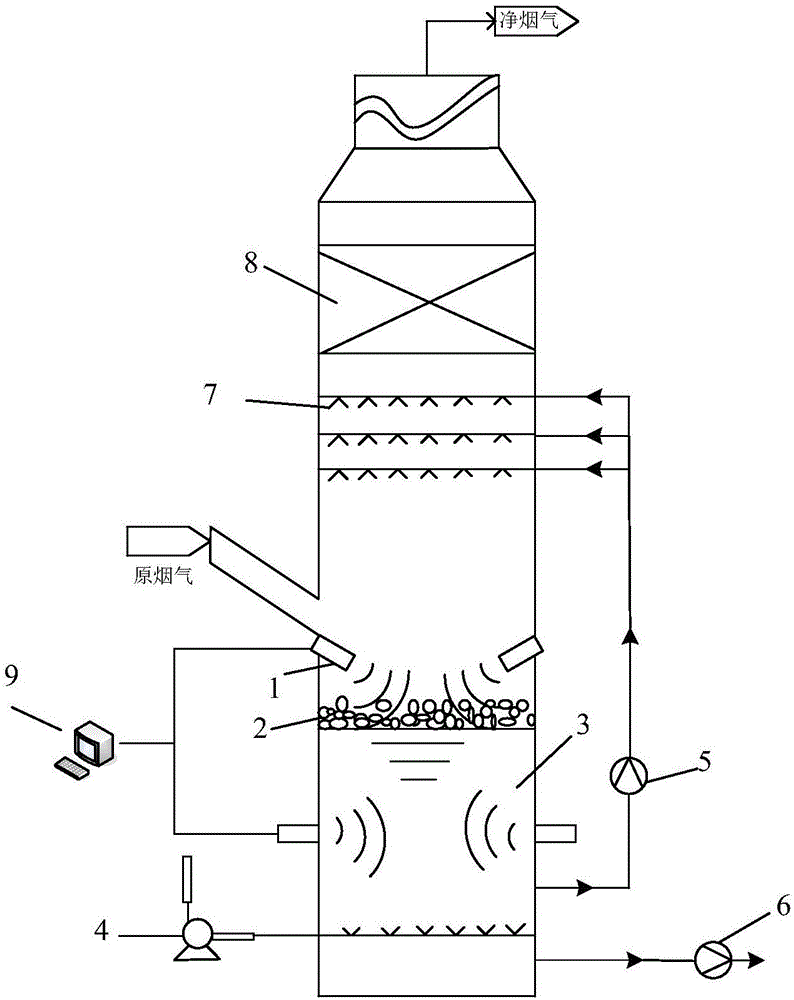

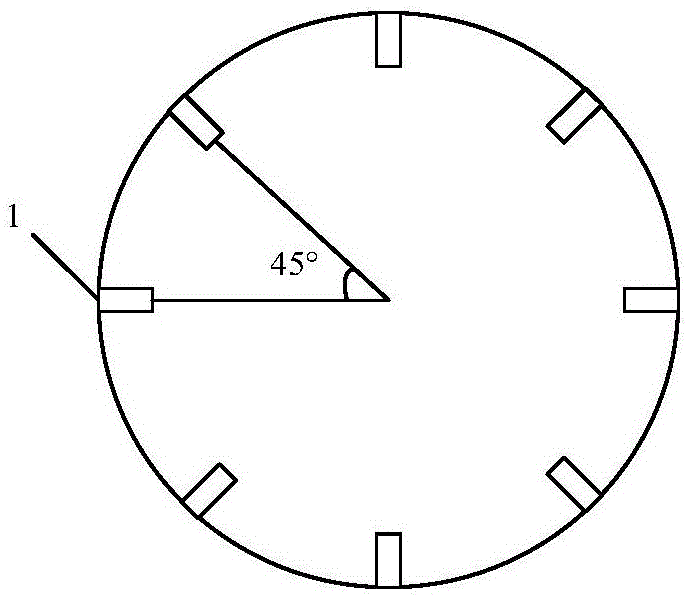

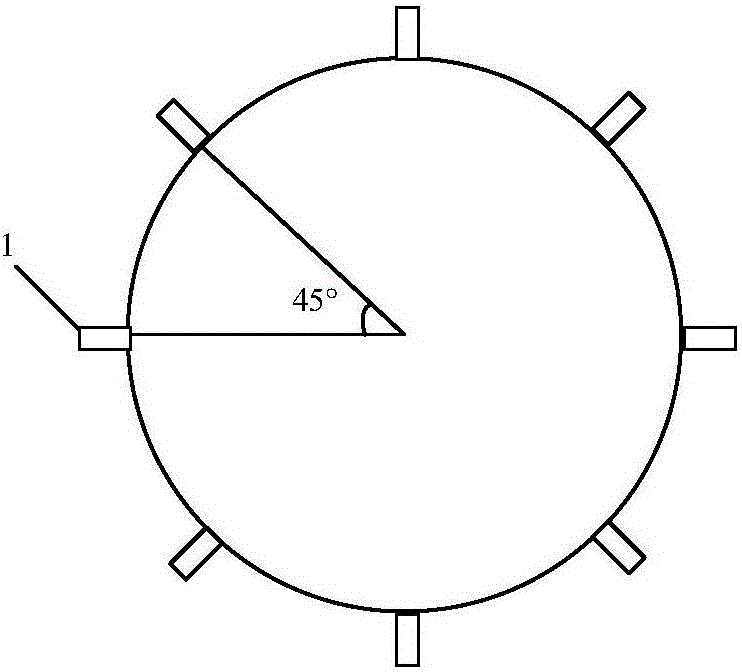

[0024] The invention discloses a method for eliminating foam in a desulfurization slurry tank by ultrasonic waves. The ultrasonic wave is used to vibrate and compress the foam on the liquid surface of the slurry tank 3 in a wet desulfurization system, so as to promote foam rupture and realize foam elimination. Wherein, the frequency of the ultrasonic wave is 60-300 Hz, and the transmitting power is 3-6KW. The ultrasonic waves act on the foam on the liquid surface of the slurry tank 3 and the upper part of the oxidation section in the slurry tank 3 at the same time. While eliminating foam, the use of ultrasonic waves at two different positions can promote the chemical reaction in the desulfurization slurry to a certain extent during the stirring process of the desulfurization slurry and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com