Ultrasonic transducer with vibration reduction function

An ultrasonic and transducer technology, applied in the field of ultrasonic transducers, can solve the problems such as the decrease in the repeatability of the transducer positioning accuracy, the inability to produce high-precision products, and the inability to guarantee the stability of the transducer, so as to save post-maintenance. , avoid errors, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

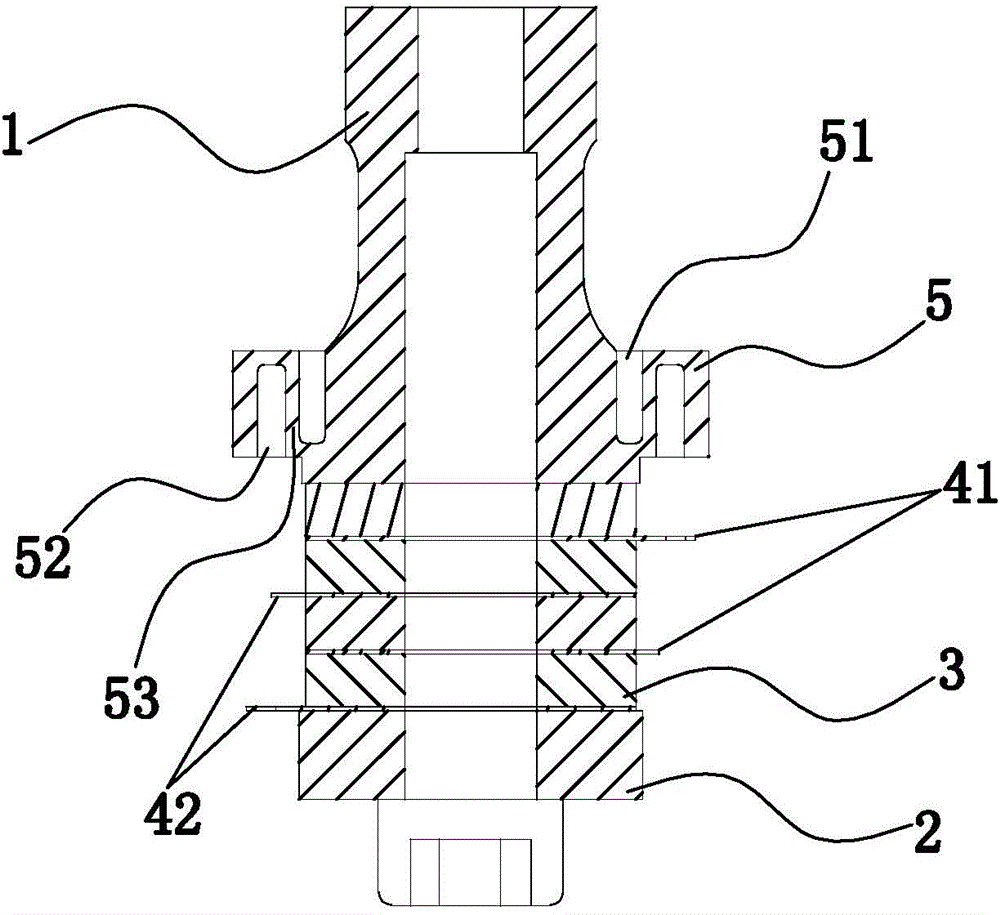

[0014] like figure 1 As shown, the present invention provides an ultrasonic transducer with vibration damping function, comprising a front cover 1 and a rear cover 2, and between the front cover 1 and the rear cover 2 are a plurality of ceramic sheets arranged at intervals 3 and electrode pads. In practical applications, the number of ceramic sheets 3 and electrode sheets arranged at intervals between the front cover plate 1 and the rear cover plate 2 are both two, four or six. In this embodiment, four ceramic sheets 3 and four electrode sheets are arranged between the front cover plate 1 and the rear cover plate 2, and the ceramic sheets 3 and the electrode sheets are arranged at intervals. The electrode sheet includes a positive electrode sheet 41 and a negative electrode sheet 42, and the positive electrode sheet 41 and the negative electrode sheet 42 are spaced apart from each other. The ceramic sheet 3 is in contact with the front cover 1 , and the electrode sheet is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com