A positioning device and positioning method for a stacking material channel

A positioning device and stacking technology, which is applied to the positioning device of the stacking channel and the field of the material channel, can solve the problems of inability to change models and realize long-term unmanned automation, etc., to achieve simple model changes and long-term unmanned The effect of automation and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

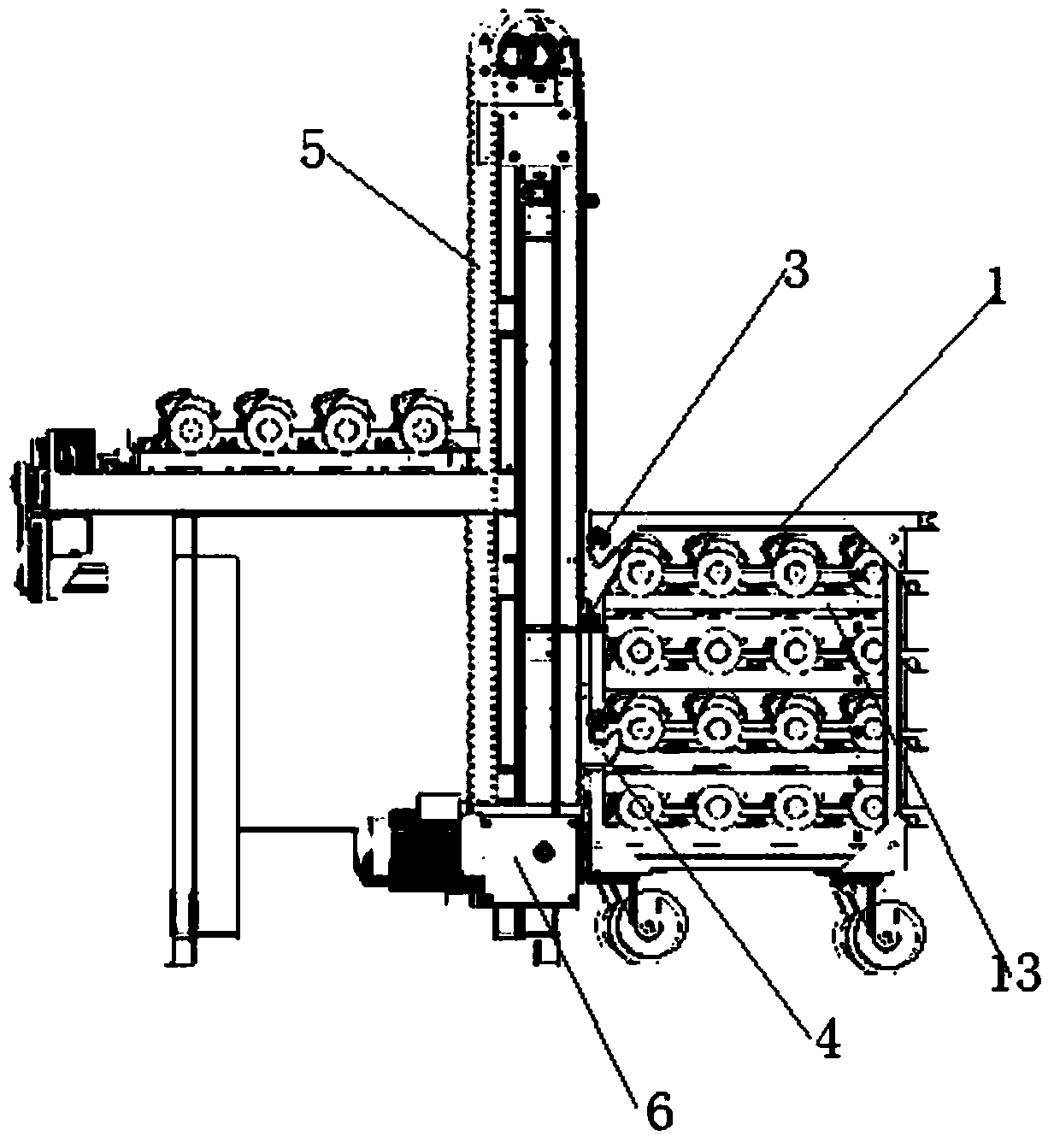

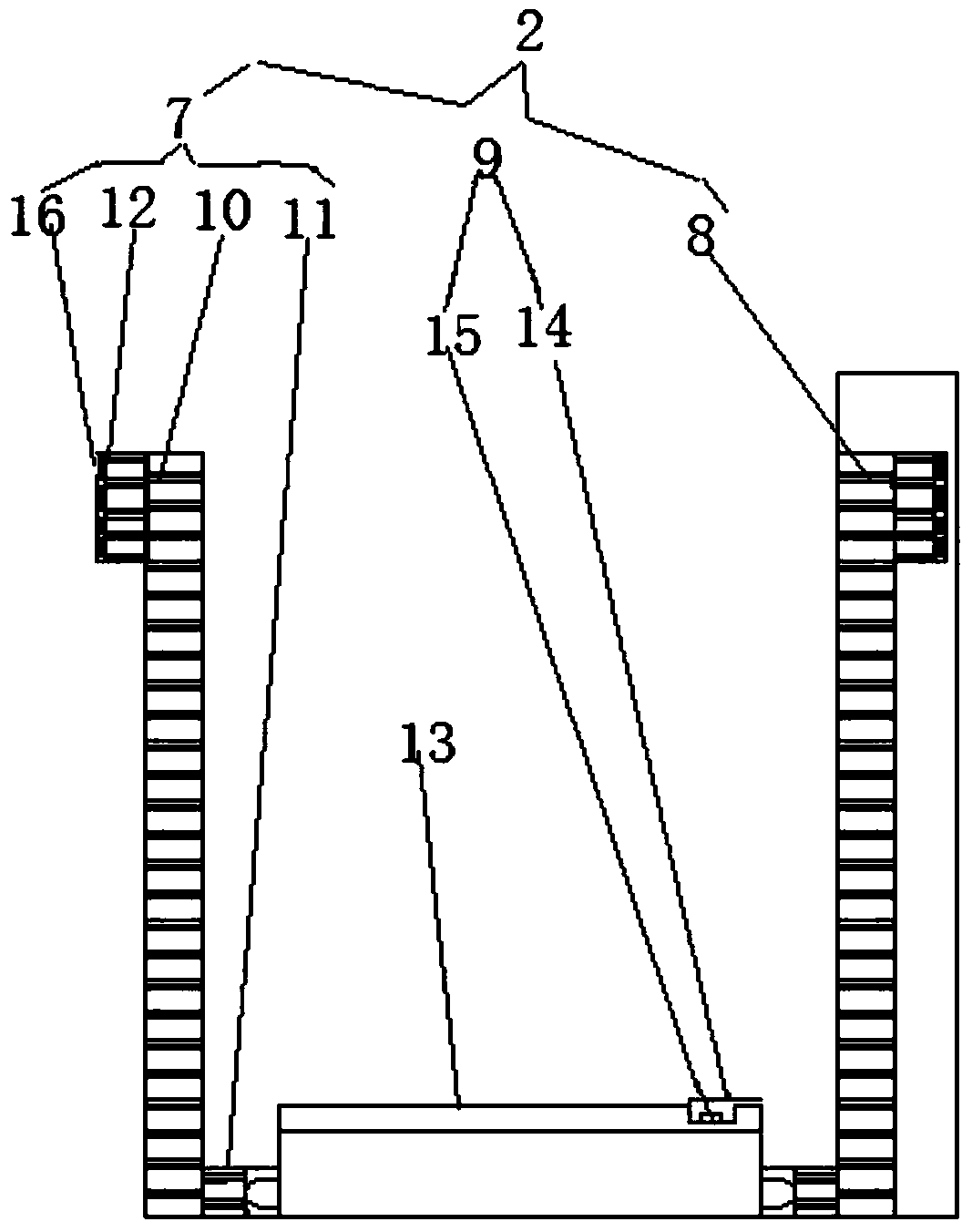

[0019] Such as figure 1 with figure 2 As shown, the positioning device of the stacking channel of the present invention includes a drawer-type stacking material box 1 and a positioning assembly 2, and a hanging column 3 arranged on the side of the drawer-type stacking box; the hanging column 3 passes through a hook 4 And the conveyor belt 5 is connected to the servo motor 6; the positioning assembly 2 includes a left grating positioning piece 7, a right grating positioning piece 8 and a layer grating positioning piece 9; the left grating positioning piece 7 and the right grating positioning piece 8 include a grating guide rail 10 , And a grating light-emitting element 11 installed on the grating guide rail at one end, and a grating light emitting element 11 installed on the side of the box at the other end; and a grating receiver 12 installed on the top of the other side of the grating rail; the layer grating positioning element 9 includes a drawer type The rail groove 14 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com