Pushing and cutting device

A cutting device and installation box technology, applied in special forming/shaping machines, wood processing appliances, manufacturing tools, etc., can solve the problems of low efficiency of manual cutting, work fatigue of staff, and high maintenance costs, and achieve strong novelty. , The effect of low maintenance cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

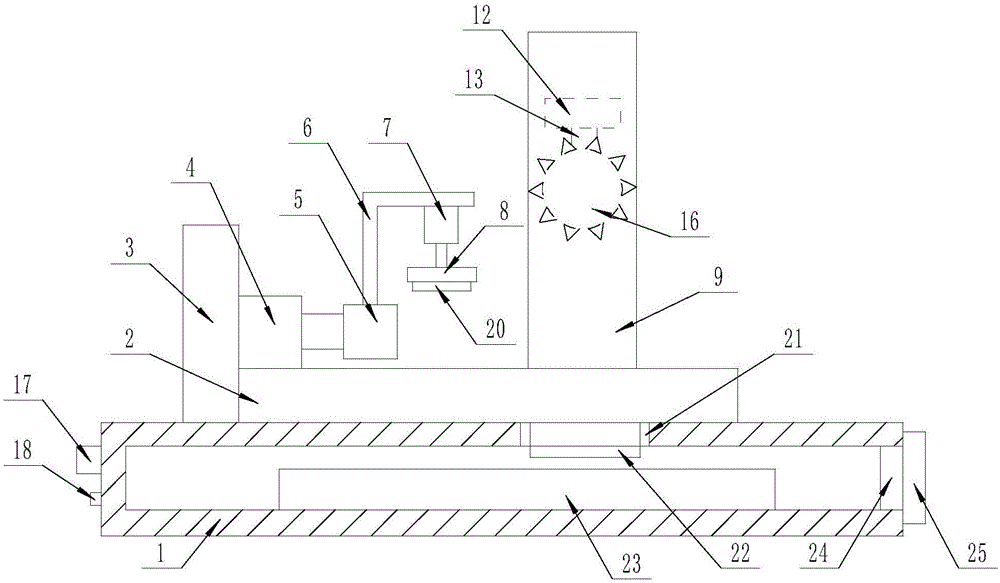

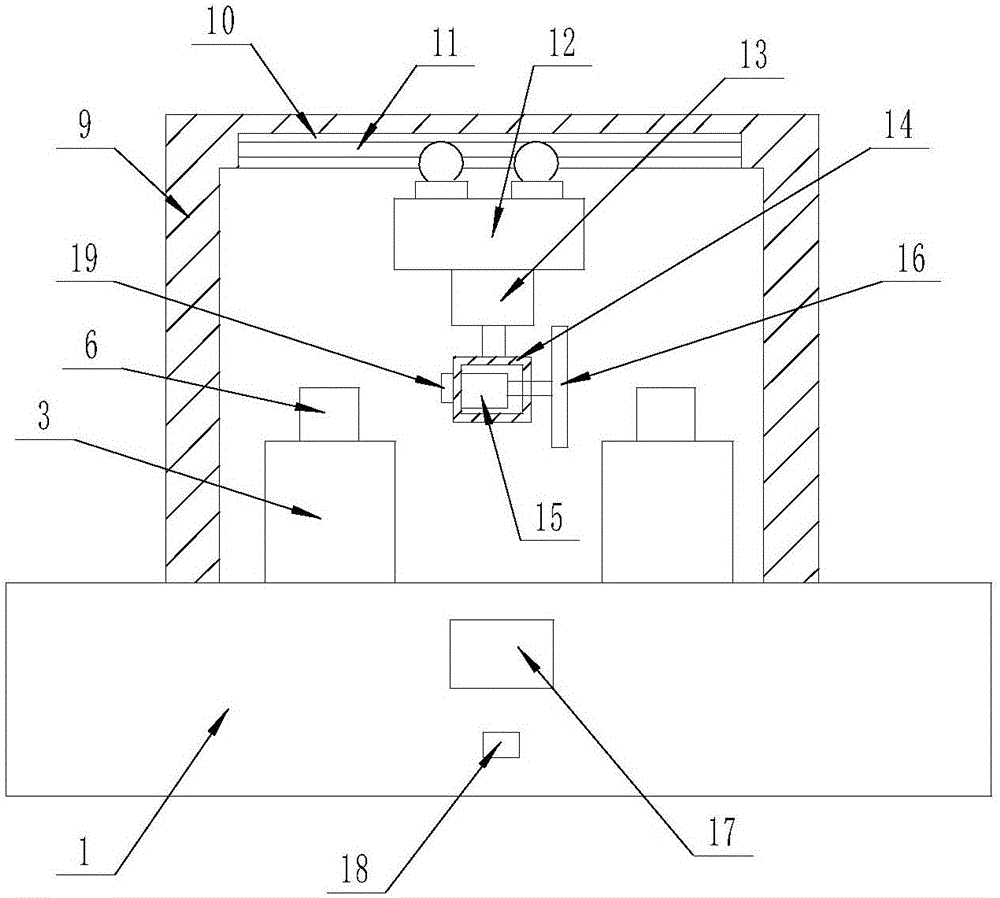

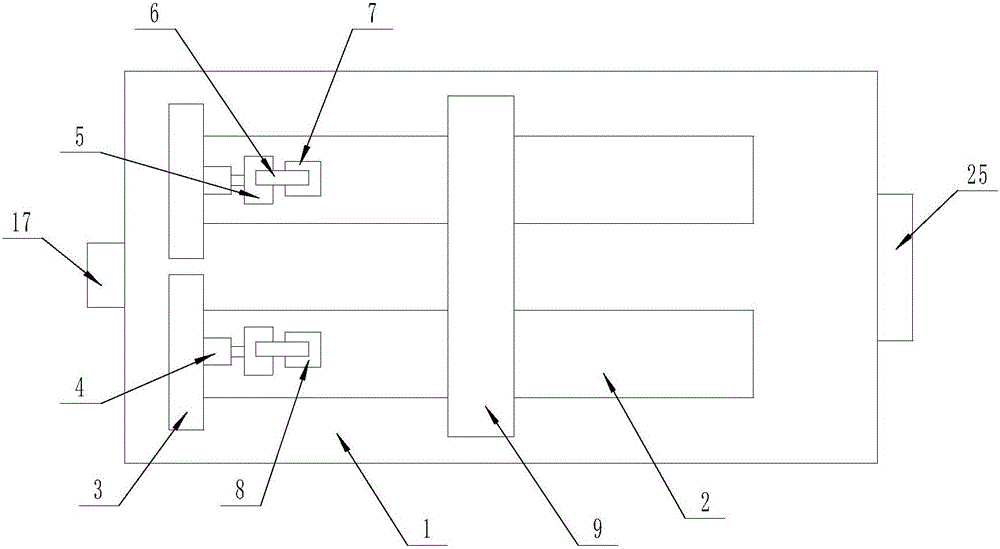

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a push cutting device includes a workbench (1), the interior of the workbench (1) is a cavity structure, the upper surface of the workbench (1) is provided with a group of carrier plates (2) parallel to each other, One end of each of the carrier plates (2) is provided with a top plate (3), and each of the top plates (3) is provided with a linear motor (4) with a telescopic end in a horizontal direction, and each of the linear motors (4) ) telescopic ends are all provided with a top block (5), each of the top blocks (5) is provided with an L-shaped bracket (6) on the upper surface, and each of the L-shaped brackets (6) is provided with a telescopic end on the lower surface Downward micro-telescopic cylinder (7), each of the micro-telescopic cylinders (7) is provided with a pressing plate (8) at the telescopic end, and the upper surface of the workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com