Injection device of precision injection machine

An injection device and injection molding machine technology, applied in the field of precision injection molding machines, can solve the problems of limited space, inability to assemble and apply the transmission structure, low energy consumption and low cost, and achieve small footprint, avoid accidental burns, and good use safety and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

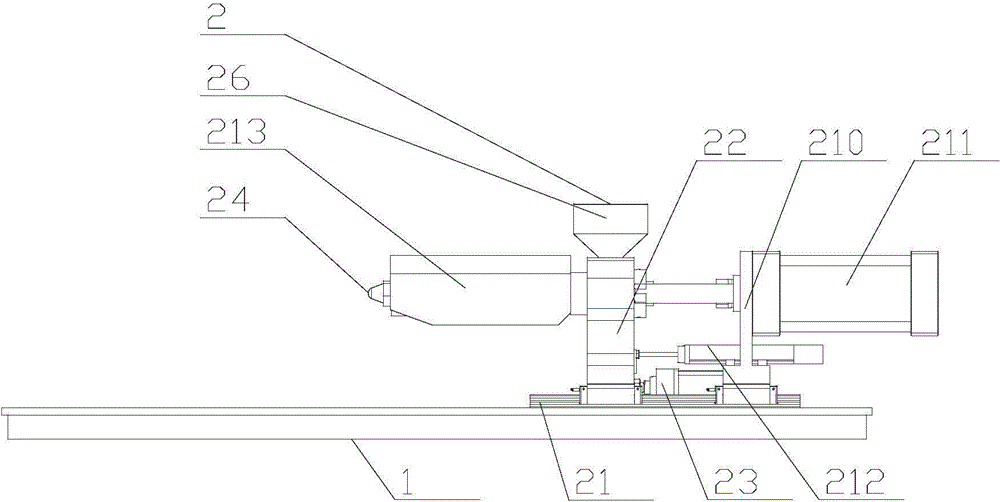

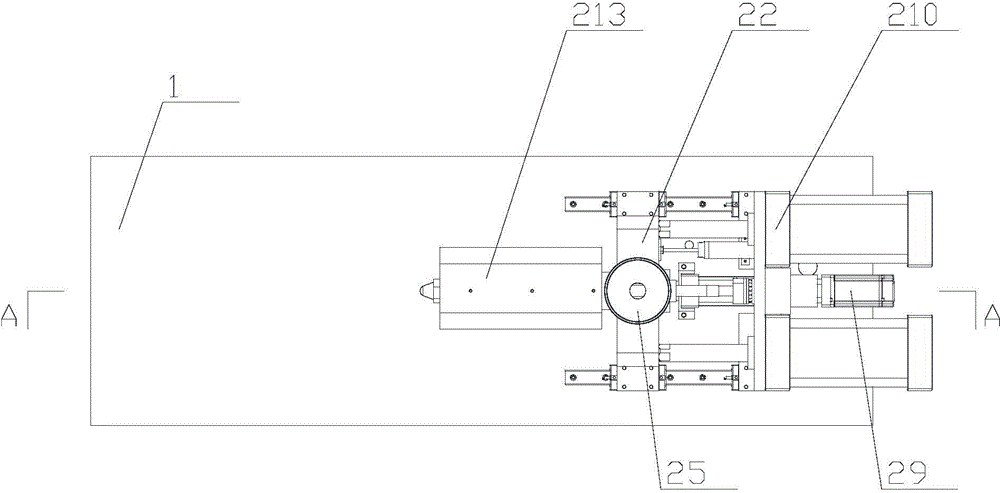

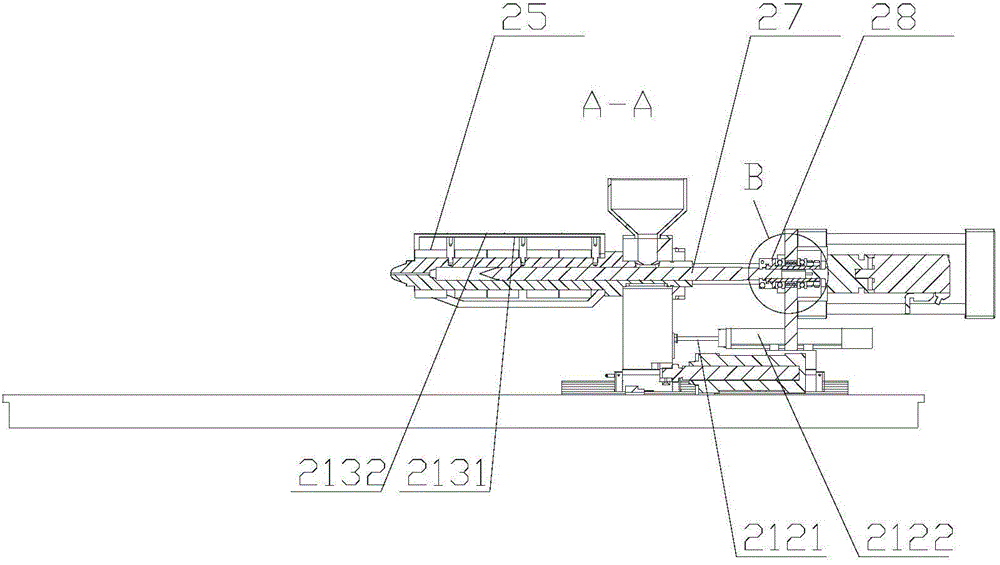

[0020] The present invention as Figure 1-5 As shown, including workbench 1, injection device 2 and clamping device 3,

[0021] The injection device 2 includes a slide rail 21, a base 22, a base driver 23, an injection tube 24, a heating jacket 25, a feed hopper 26, a screw 27, a coupling 28, a screw driver 29, a slide 210 and Slider driving device 211; the slide rail 21 and the base driving device 23 are arranged in the same direction, and are fixedly connected to the top surface of the workbench 1 of the injection molding machine, the base 22 and the slide seat 210 are arranged in parallel, and The bottoms of both are slidingly connected on the slide rail 21, so that the base 22 is driven by the base driving device 23 to do linear reciprocating motion along the slide rail 21; the sliding seat driving device 211 is fixedly connected to the sliding seat 210 The end surface of the base 22 is facing away from the base 22 and has a power rod that passes through the slide seat 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com