Automatic bearing charging device

An automatic material feeding and material guiding device technology, applied in the direction of conveyor control device, support frame, transportation and packaging, etc., can solve the problem of high labor intensity of operators, monotonous and boring operation, and the failure to effectively guarantee the qualified rate of assembly, etc. problems, to achieve the effect of ensuring continuity and timeliness, improving reliability and stability, and avoiding untimely supply of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

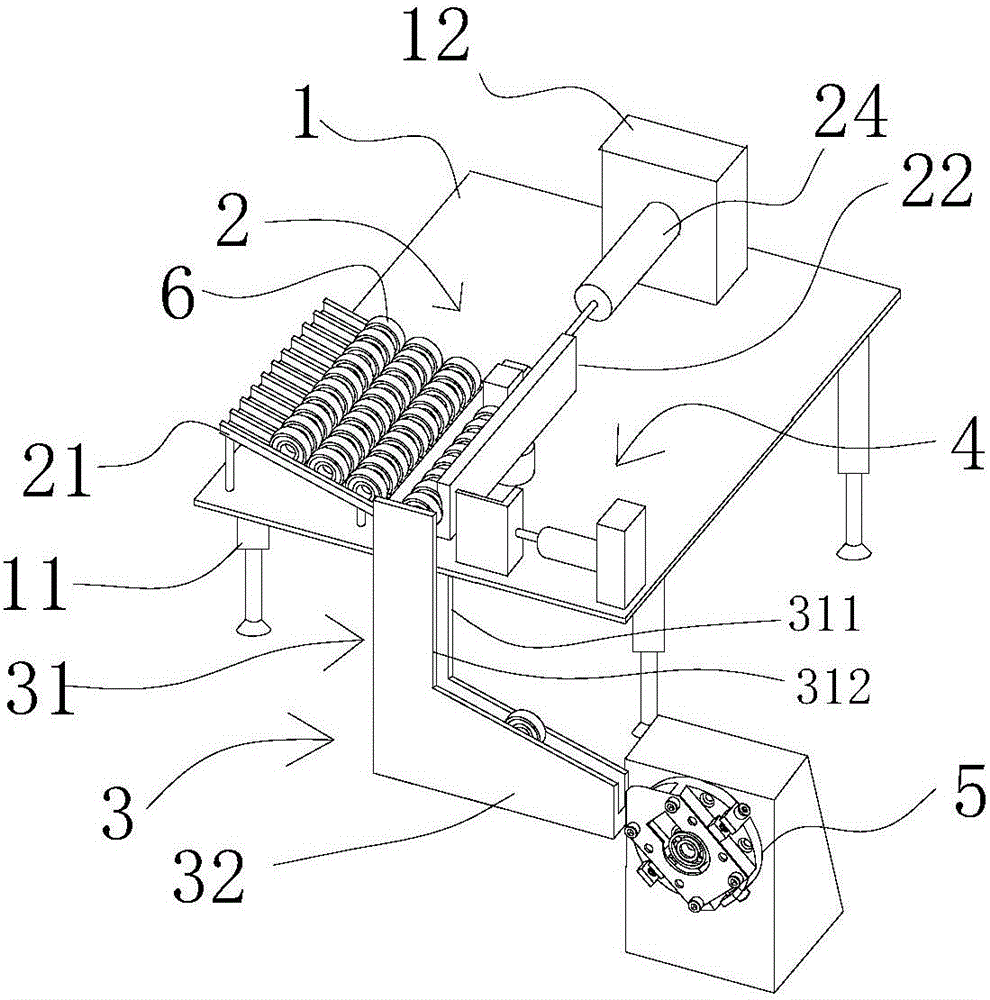

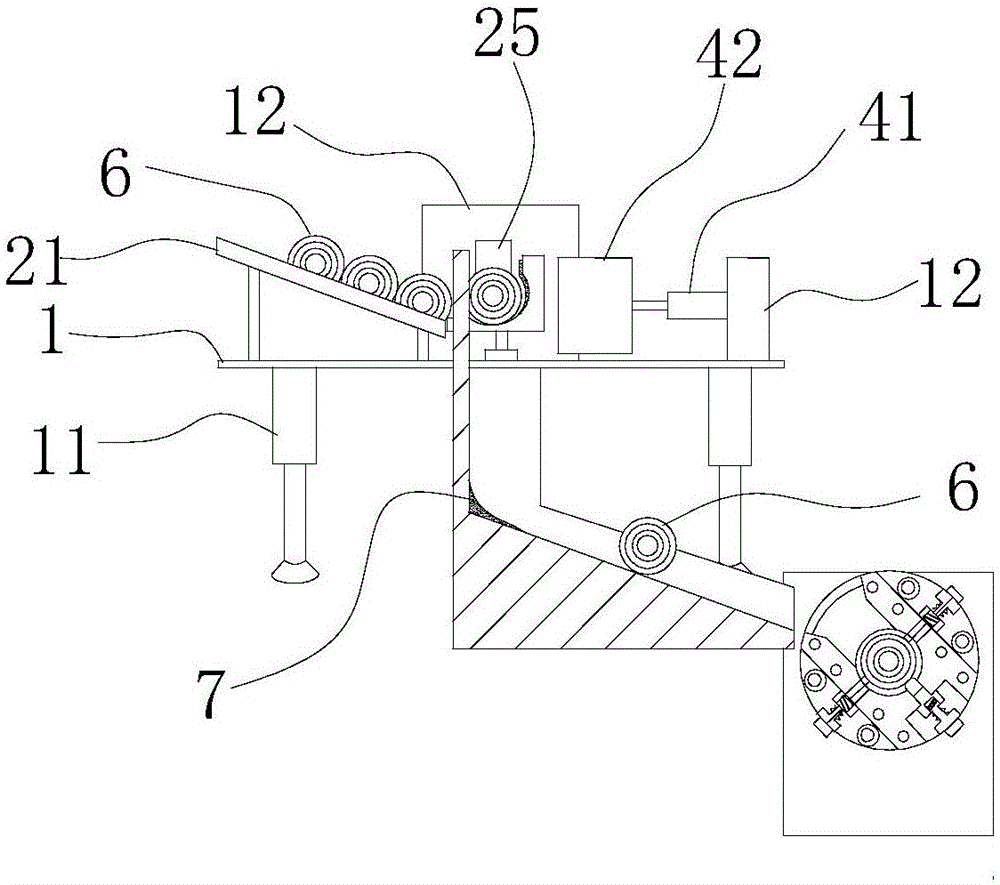

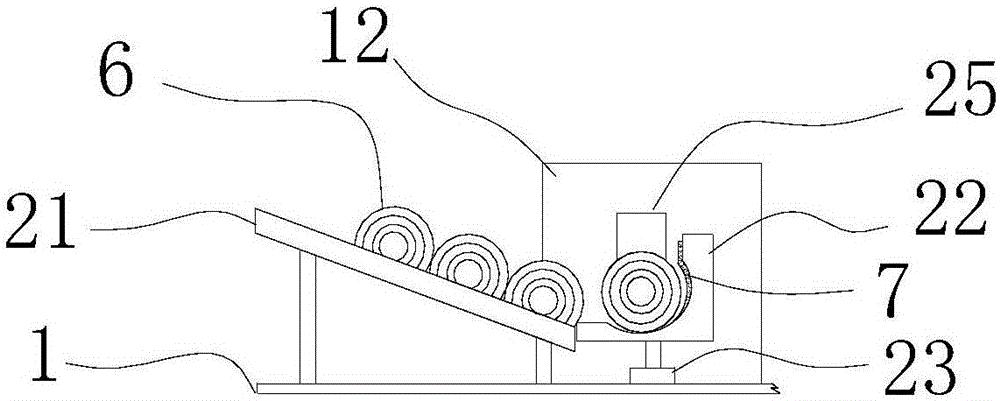

[0032] Such as figure 1 As described above, an automatic bearing feeding device, as an improvement of the present invention, includes a support platform 1, a material guide device 2 arranged on the support platform 1, and a guide device 3 arranged on the side of the support platform 1 on the side of the material guide device 2 , the material stopper 4 that is arranged between the guide device 2 and the guide device 3, the bearing crimping seat 5 that is connected with the lower end of the guide device 3, the material guide device 2 is provided with a code rack 21 with an included angle relative to the horizontal plane, The pusher baffle 22 that is L-shaped at the bottom of the code rack 21, the lifting cylinder 23 that is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com