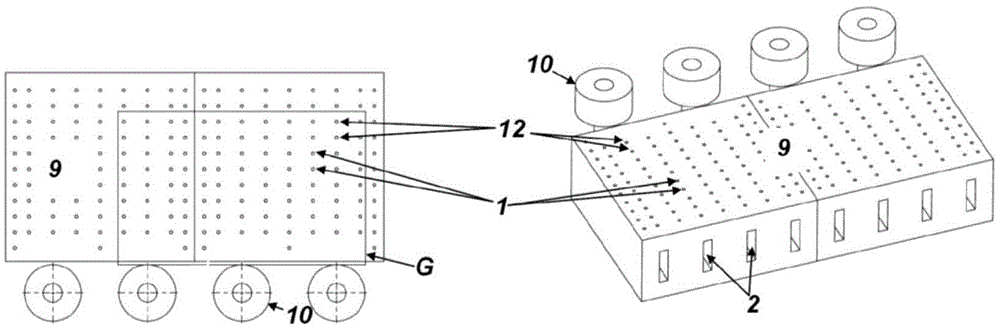

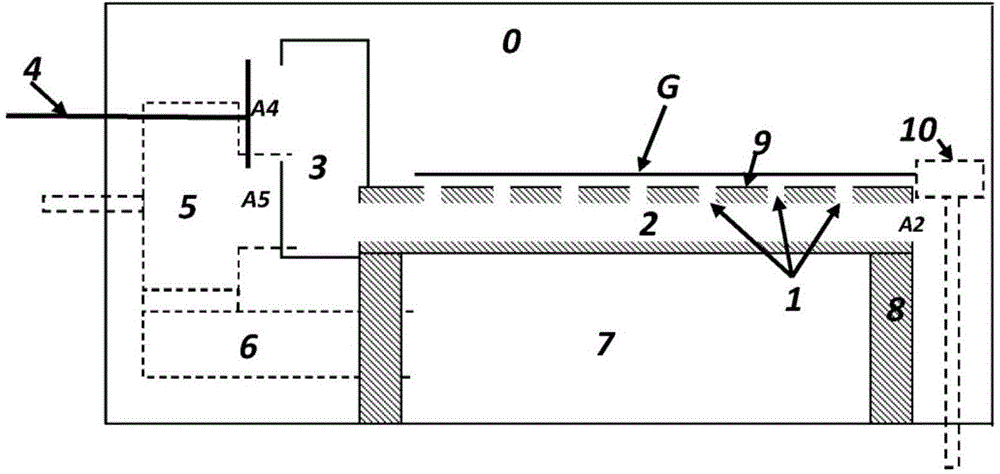

Equipment for conveying glass plates on air bearing table in heating furnace

A technology of supporting table and heating furnace, applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

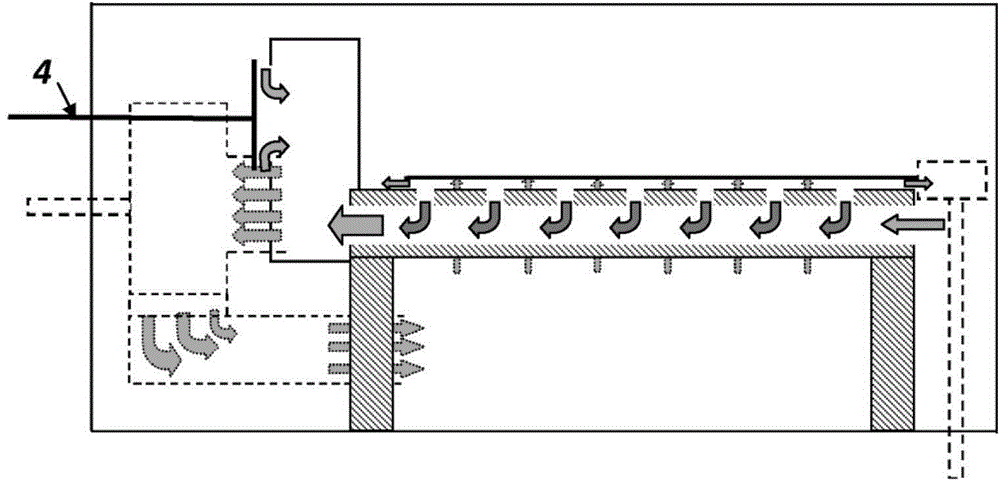

Method used

Image

Examples

example 1

[0052] Example 1: No glass on air bearing (0% load).

[0053] In the apparatus according to the invention, the suction side of the blower is 3 x A free hole area to the furnace.

[0054] In the device according to publication US 8 297 077, the suction side of the blower has a free hole area of 1.125×A leading to the furnace.

example 2

[0055] Example 2: The air bearing table is half covered with glass (loading degree 50%).

[0056] In the apparatus according to the invention, the suction side of the blower is a free hole area of 2.5×A+C×0.5×A to the furnace.

[0057] In the device according to publication US 8 297 077, the suction side of the blower is a free hole area of 0.625×ΣA+C×0.5×A to the furnace.

example 3

[0058] Example 3: The air bearing table is fully covered with glass (100% loading).

[0059] In the apparatus according to the invention, the suction side of the blower is a free hole area of 2*A+C*A to the furnace.

[0060] In the device according to publication US 8 297 077, the suction side of the blower is a free hole area of 0.125×A+C×A leading to the furnace.

[0061] In the above, the coefficient C defines how large the proportion of free vent holes is to the vent holes below the glass. The coefficient C depends on the variation of the most confined surface area of the vent hole, which follows the calculations below.

[0062] The surface area of the mouth of the free vent hole is (п / 4)D 2 , where D is the diameter of the mouth of the exhaust hole. The diameter of the mouth of the vent hole held below the glass is пDH, where H is the height of the air bed. A typical height H of the air bed is 0.5 mm and the diameter of the exhaust opening is 10 mm. Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com