A kind of flame retardant and high temperature resistant oriented strand board and its preparation method

A technology of oriented particle board and high temperature resistance, which is applied in the direction of chemical instruments and methods, manufacturing tools, flat products, etc. It can solve the problems of low bonding strength, affecting the bonding of urea-formaldehyde resin adhesives, and the decrease of chip bonding, so as to achieve flame retardancy Good performance, stable flame retardant performance, not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

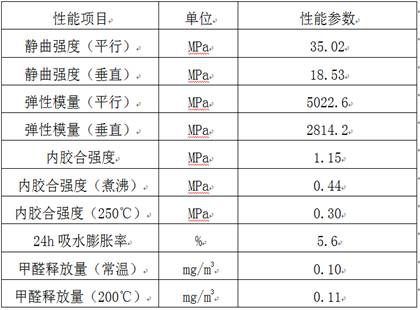

Embodiment 1

[0046] A flame-retardant and high-temperature-resistant oriented strand board, including a surface layer and a core layer;

[0047] The mass ratio of the surface layer to the core layer is 55%: 45%;

[0048] The pavement angle between the surface layer and the core layer is 45°;

[0049] The surface layer is composed of large shavings, the core layer is composed of large shavings and fine shavings, and the mass ratio of the large shavings to the fine shavings is 70%: 30%;

[0050] The size of the large shavings is 60mm in length, 12mm in width and 0.4mm in thickness;

[0051] The size of the fine shavings is 10mm in length, 4mm in width and 0.4mm in thickness.

[0052] A method for preparing flame-retardant and high-temperature-resistant oriented strand board, including shavings, initial washing of shavings, drying, re-washing of shavings, draining, balancing, curing, drying, mixing, sizing, paving, hot pressing, trimming, sanding Light.

[0053] As for the shavings, large...

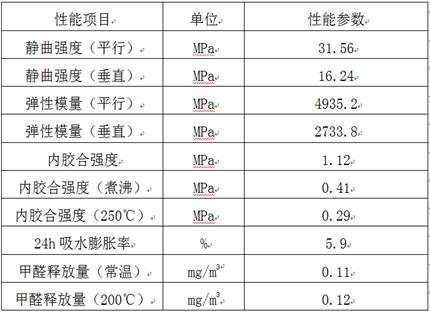

Embodiment 2

[0078] A flame-retardant and high-temperature-resistant oriented strand board, including a surface layer and a core layer;

[0079] The mass ratio of the surface layer to the core layer is 60%: 40%;

[0080] The pavement angle between the surface layer and the core layer is 90°;

[0081] The surface layer is composed of large shavings, the core layer is composed of large shavings and fine shavings, and the mass ratio of the large shavings to the fine shavings is 80%: 20%;

[0082] The size of the large shavings is 90mm in length, 25mm in width and 0.9mm in thickness;

[0083] The size of the fine shavings is 25mm in length, 6mm in width and 0.9mm in thickness.

[0084] A method for preparing flame-retardant and high-temperature-resistant oriented strand board, including shavings, initial washing of shavings, drying, re-washing of shavings, draining, balancing, curing, drying, mixing, sizing, paving, hot pressing, trimming, sanding Light.

[0085] As for the shavings, large...

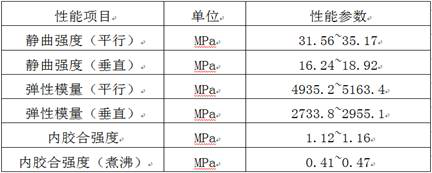

Embodiment 3

[0110] A flame-retardant and high-temperature-resistant oriented strand board, including a surface layer and a core layer;

[0111] The mass ratio of the surface layer to the core layer is 70%: 30%;

[0112] The pavement angle between the surface layer and the core layer is 70°;

[0113] The surface layer is composed of large shavings, the core layer is composed of large shavings and fine shavings, and the mass ratio of the large shavings to the fine shavings is 75%: 25%;

[0114] The size of the large shavings is 120mm in length, 18mm in width, and 0.6mm in thickness;

[0115] The size of the fine shavings is 18mm in length, 5mm in width and 0.6mm in thickness.

[0116] A method for preparing flame-retardant and high-temperature-resistant oriented strand board, including shavings, initial washing of shavings, drying, re-washing of shavings, draining, balancing, curing, drying, mixing, sizing, paving, hot pressing, trimming, sanding Light.

[0117] As for the shavings, lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com