Rigid drainage pile and construction method thereof

A construction method and technology of drainage piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that the pile body concrete is easy to shrink, segregate, have no improvement effect, reduce pile side resistance, etc., and achieve bearing capacity High, increased strength, the effect of increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

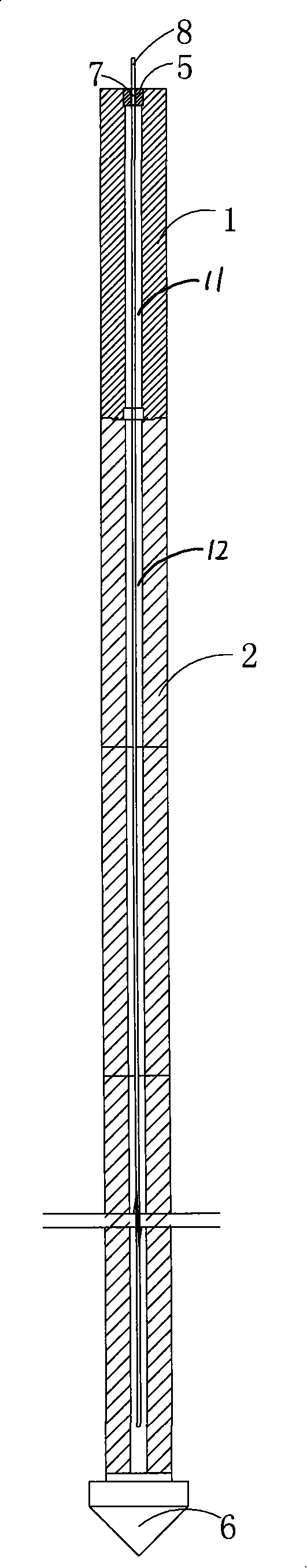

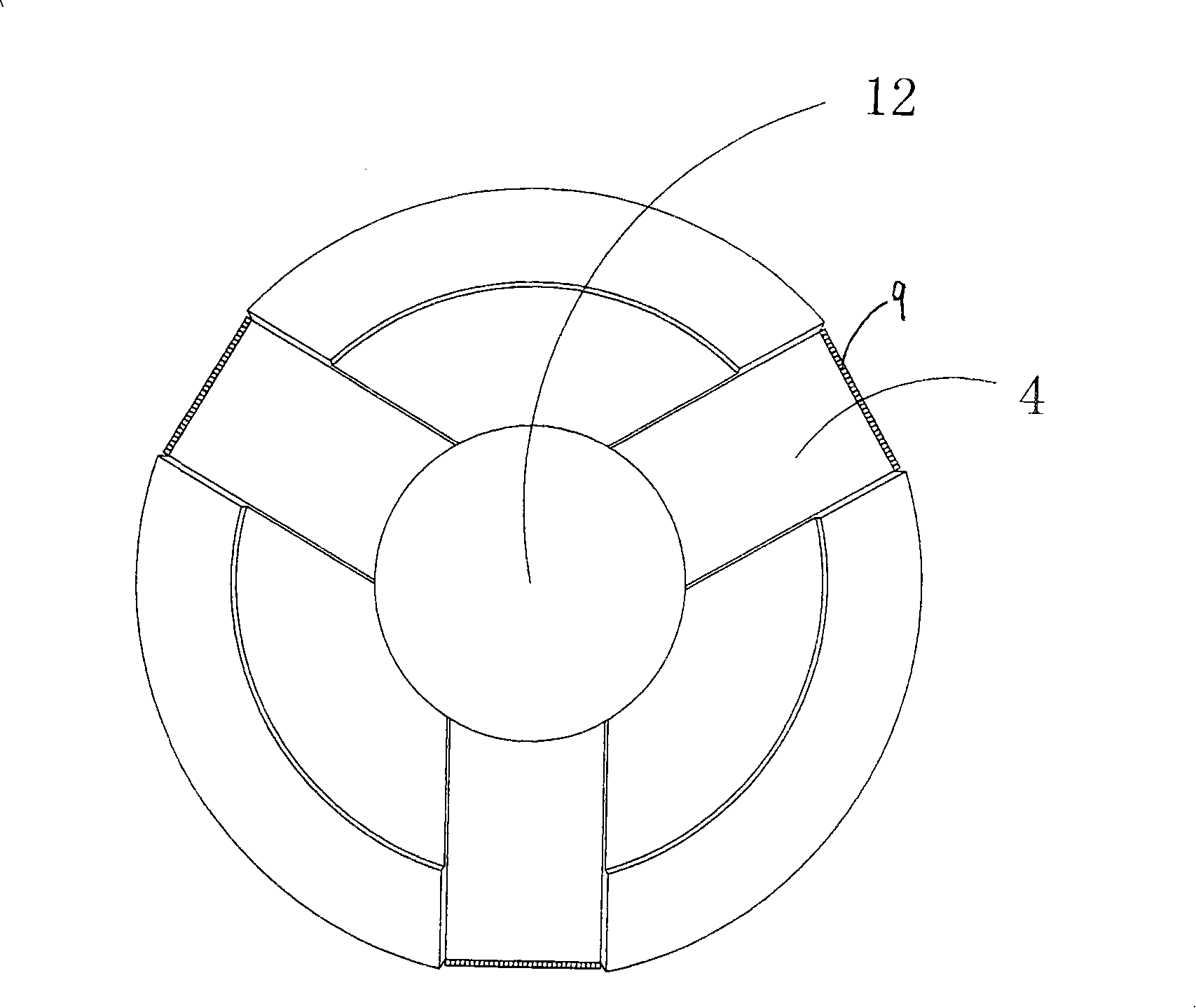

[0023] Embodiment: A rigid drainage pile is composed of a prefabricated impermeable concrete pipe 1 and at least one section of prefabricated permeable concrete pipe 2. The prefabricated impermeable concrete pipe and the prefabricated permeable concrete pipe are respectively provided with first and second axial through holes 11, 12, the first and second through holes are sealed and communicated, and the second through holes on adjacent prefabricated permeable concrete pipes are sealed and communicated with each other.

[0024] A permeable structure of the prefabricated permeable concrete pipe is: the pipe wall is made of permeable concrete.

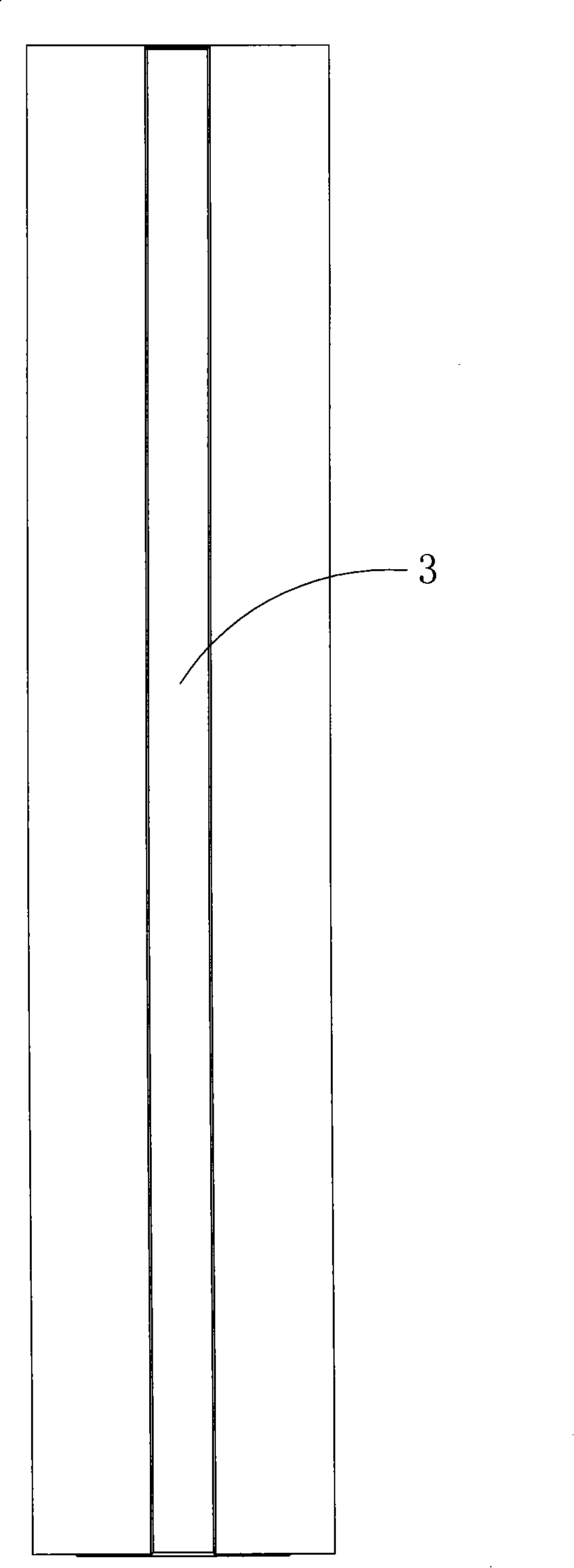

[0025] Another permeable structure of the prefabricated permeable concrete pipe is: the facade of the prefabricated concrete pipe is provided with at least one axial first drainage groove 3, and at least one of the upper and lower end surfaces of the prefabricated concrete pipe is provided with a first drainage groove 3. Two drainage groo...

example

[0041] Example: A project builds 5000m on the weak coastal foundation 3 There are 5 steel oil storage tanks. The foundation of the oil tank is reinforced concrete slab foundation. The load at the bottom of the foundation is 200kPa. The stratum conditions are shown in the table below:

[0042] Physical and mechanical index of foundation soil

[0043] serial number

Thickness (m)

Moisture content (%)

Severity (kN)

Compression modulus (MPa)

Ultimate side resistance (kPa)

Ultimate terminal resistance (kPa)

1

Silty Clay

0.5

27.9

19.1

0.79

5.19

15

2

Silty Clay

0.6

35.8

18.4

0.97

4.19

15

3

Silty clay soil

6.7

55

16.5

1.52

2.01

15

4

muddy silty clay

8.8

46.4

17.2

1.27

2.65

25

5

4.8

3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com