Composite hollow grid-like structural plate and manufacturing method

A production method and technology of structural panels, which are applied in the on-site preparation of building components, building structure, formwork/template components, etc., can solve the problem that the molding effect is not as good as the one-time molding surface layer, the processing technology of special-shaped ribs is complicated, and the product specifications are fixed. and other problems, to achieve the effect of reducing the number of manual cleaning of the surface cement, light weight, and excellent casting and molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

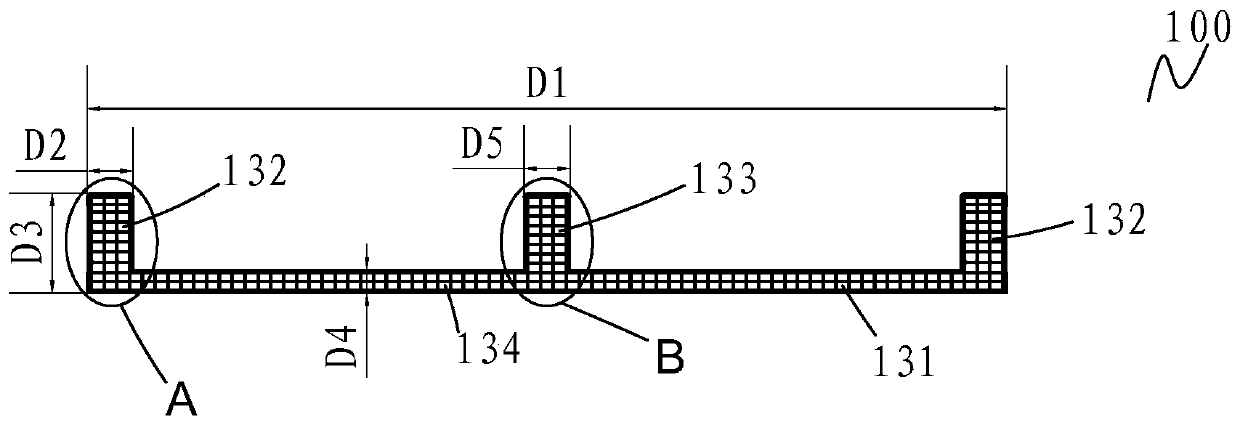

[0082] Example: such as Figure 7 As shown, the upper and lower ends of the composite hollow structural panel 100 shown are respectively sealed with head plates 200 . The head plate is used to seal the upper and lower ends to protect the upper and lower ends, prevent the product from being broken when it falls and prevent slurry leakage, and at the same time provide a connection structure for the upper and lower ends. Two symmetrical blocks 2001 protrude from the lower end of the head plate 200, and the grooves formed by each of the side ribs 132 and the middle rib 133 match the blocks 2001. The two blocks 2001 directly have a receiving groove 2002, and the middle The reinforcing rib 133 is embedded in the receiving groove 2002, and the clamping block 2001 is embedded in the groove so as to install the head plate on the end of the composite hollow structural plate 100, and the head plate 200 and the composite hollow structural plate The left and right side surfaces and the re...

Embodiment 1

[0096] The production line of the manufacturing method includes a single-screw extruder 1, a hydraulic screen changer 2, an extrusion die 3, a shaping die 4, a shaping device 5, a tractor 6, a first set of unwinding racks 7, and a second set of unwinding racks 8. Limiting roller 9, two-channel oven 10, two-roll laminating device 11, single-channel oven 12, groove folding device 13, third set of unwinding rack 14, unwinding rack platform 15, three-channel oven 16, laminating Device 17, twin-screw extruder 18, the second hydraulic screen changer 19, covering mold 20, the second calibrating die 21, the second calibrating device 22, the second tractor 23, cutting machine 24, longitudinal conveying device 25, Lateral conveying device 26;

[0097] Step S1, extruding the plastic filling layer 130; extruding the plastic filling layer 130 through the single-screw extruder 1, adding raw materials in the single-screw extruder 1, for example, ordinary plastic raw materials can be used, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com