Device for achieving wet spinning through fine spray and achieving bundling yarn forming

A bunching and yarn forming technology, applied in textiles and papermaking, etc., can solve the problems of not being able to produce various yarns and various special-shaped yarns, complicated operation and maintenance, high energy consumption, etc., to reduce labor and equipment investment, easy to The effect of less damage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

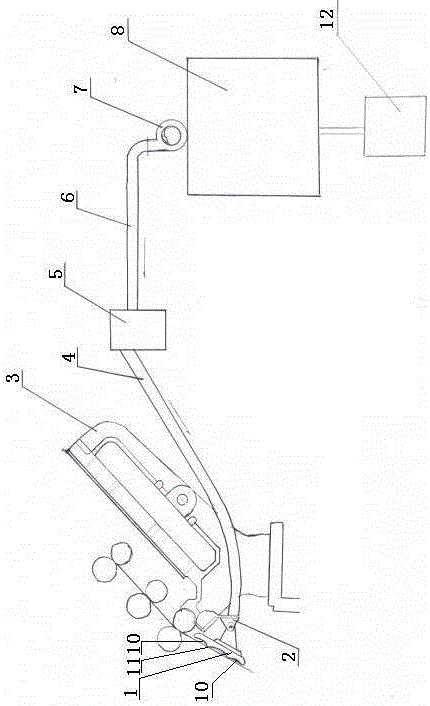

[0019] like figure 1 As shown, the present invention has a trough-shaped spray tank 9 for the yarn to pass through in the tank, and a nozzle 10 is arranged at the bottom of the spray trough, and the nozzle 10 communicates with the atomizing generator 8 through an air duct, so that the atomizing generator 8 The generated mist is sprayed on the yarn in the spray tank 10 through the spray tank.

[0020] A fan 7 is arranged between the atomizing generator and the nozzle, and the fan 7 delivers the mist generated by the atomizing generator to the nozzle through the first air pipe 6 , the main air pipe 5 and the second air pipe 4 .

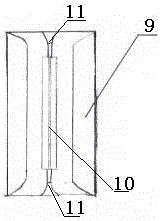

[0021] The spray tank assembly 1 includes a spray tank 9, a nozzle 10, and a groove contact 11. The spray tank assembly 1 is connected with a hinged seat 2 by a living connection structure, and the hinged seat 2 is fixed on the front roller bearing of the roller stool 3. The adjustable mechanism is used to adjust the swing angle of the spray tank after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com