Valve drive lubrication for internal combustion engines

A transmission device and lubrication device technology, which is applied in the direction of engine lubrication, valve accessories lubrication, valve device, etc., can solve the problems of increased rotation resistance of the camshaft, deterioration of the installation of the camshaft, etc., and achieve the effect of suppressing the sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

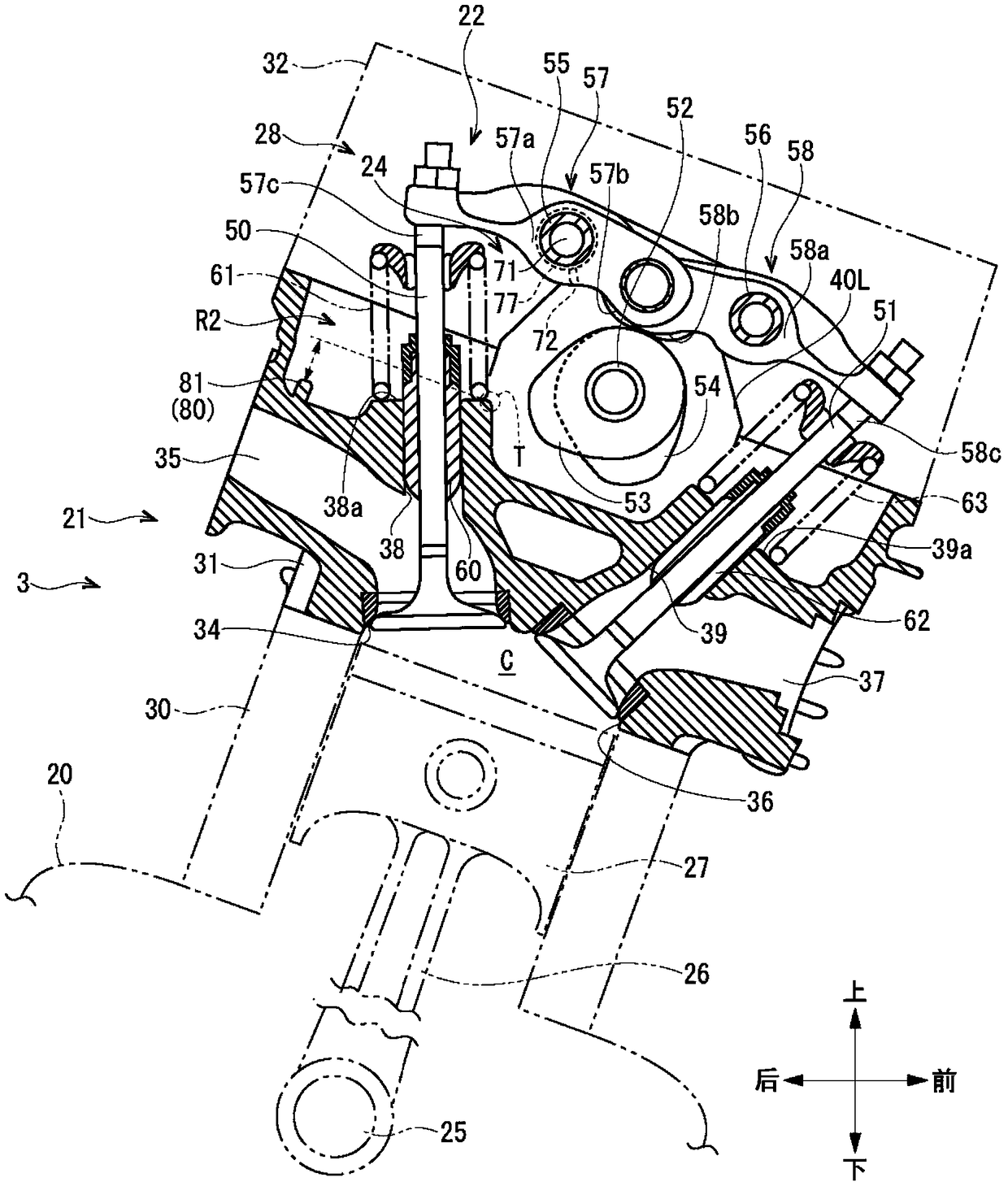

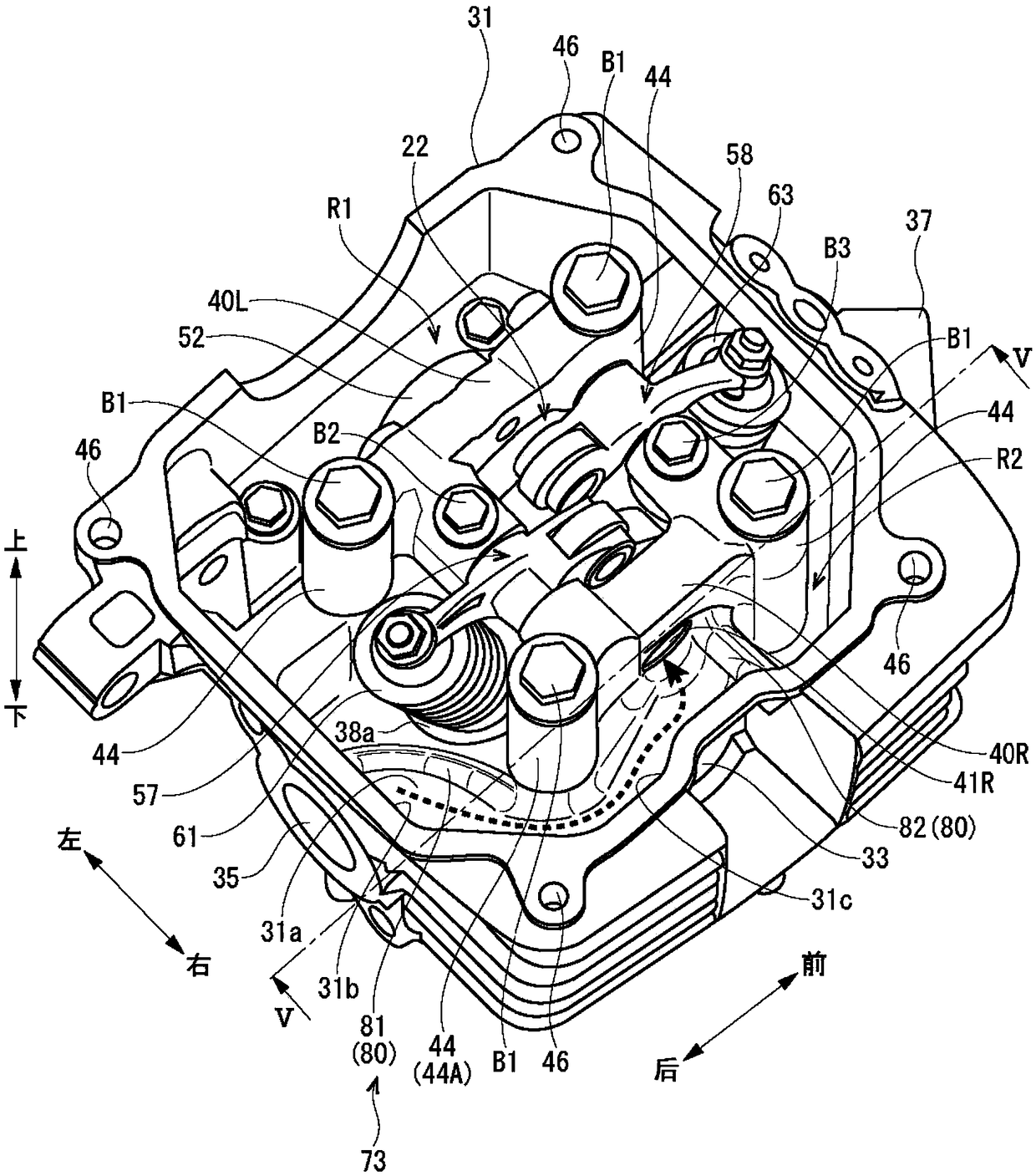

[0073] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

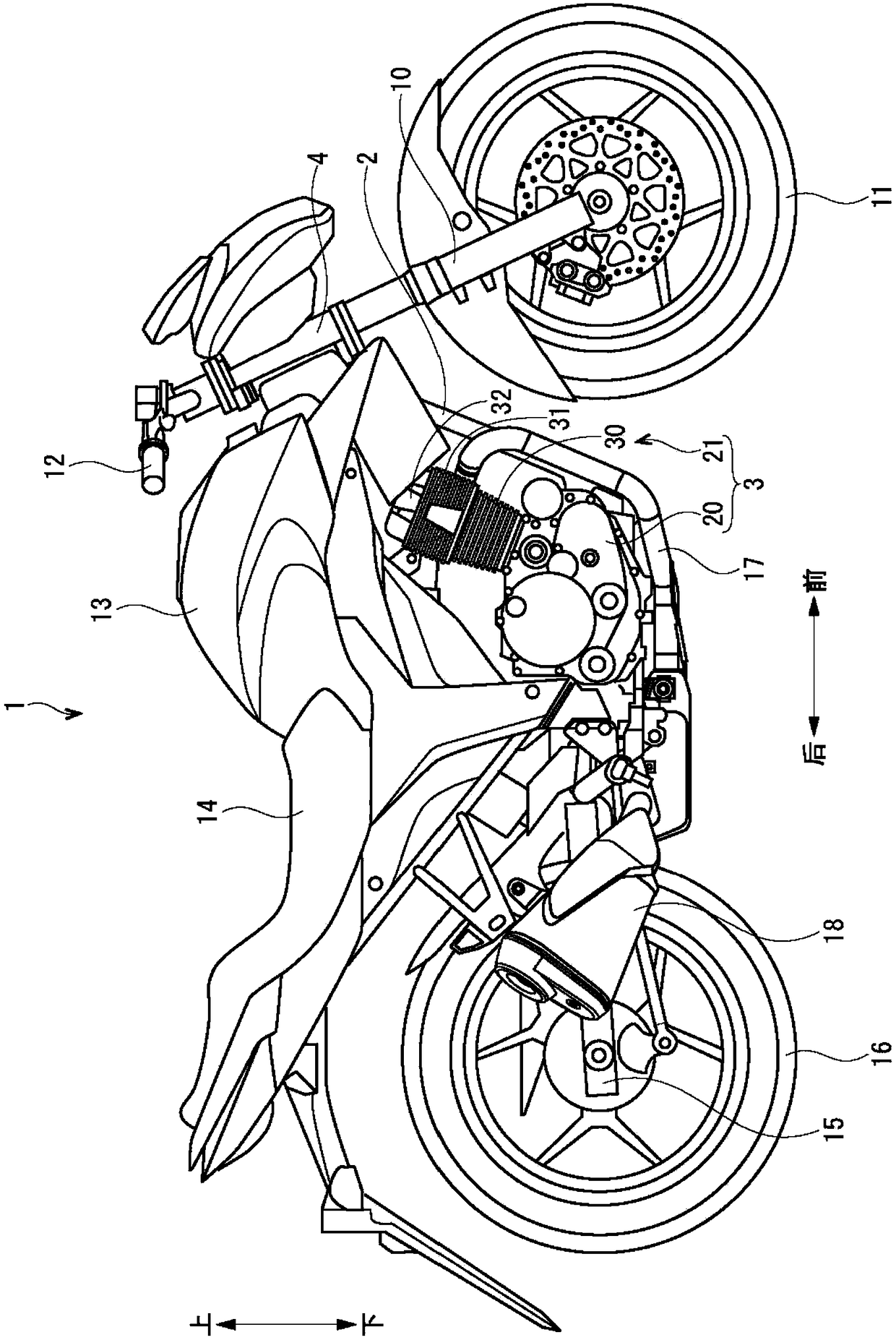

[0074] refer to figure 1 The overall structure of the motorcycle 1 will be described. figure 1 A side view of the motorcycle 1 is shown. In addition, below, each direction is set based on the occupant who rides on the motorcycle 1, and it demonstrates based on the direction shown in each figure.

[0075] The motorcycle 1 is roughly configured to include a body frame 2 and an engine 3 .

[0076] The vehicle body frame 2 is formed by welding pipes made of steel or aluminum alloy. A head pipe 4 is fixed to a front portion of the vehicle body frame 2 , and the head pipe 4 rotatably supports a pair of left and right front forks 10 . The front wheel 11 is rotatably supported on the lower portion of the front fork 10 . A handle 12 is provided on an upper portion of the front fork 10 .

[0077] A fuel tank 13 for storing fuel (such as gasoline) is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com