High-efficiency and low-cost heat dissipation protection mechanism of LED light

A technology for LED lamps and protection mechanisms, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., and can solve problems such as excessive consumables, increased initial purchase costs of LED lamps, and low heat transfer and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

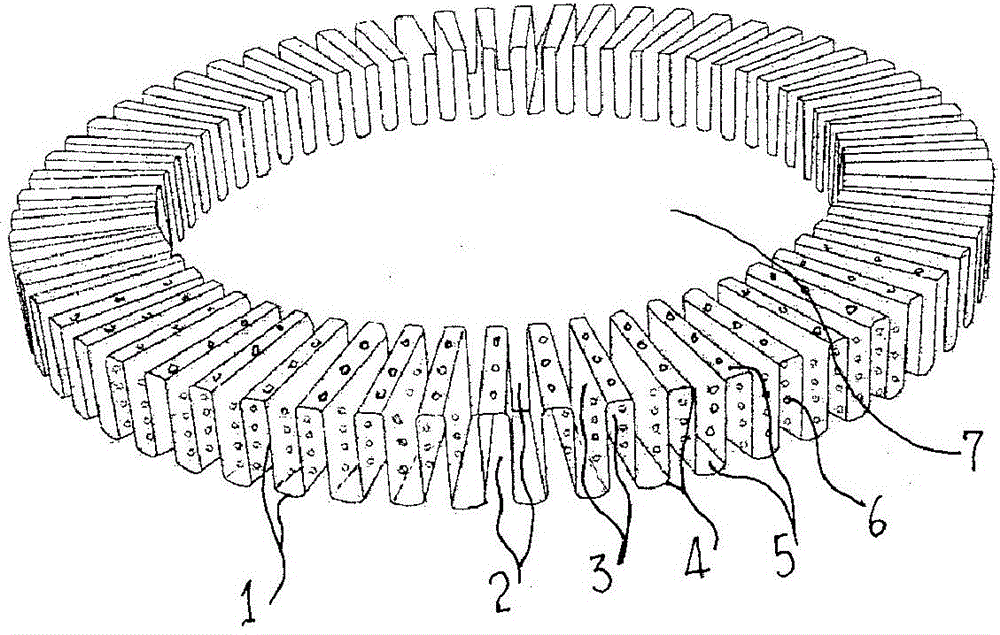

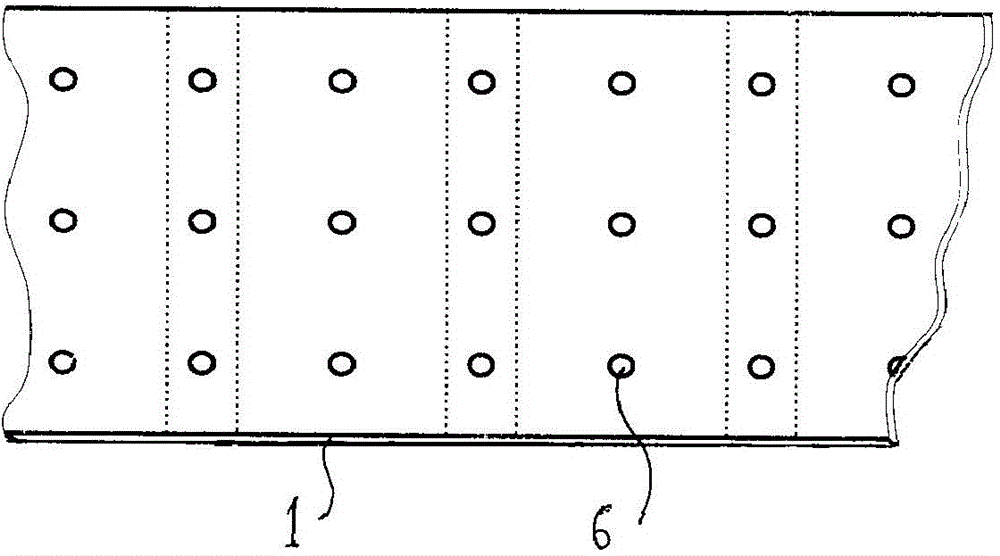

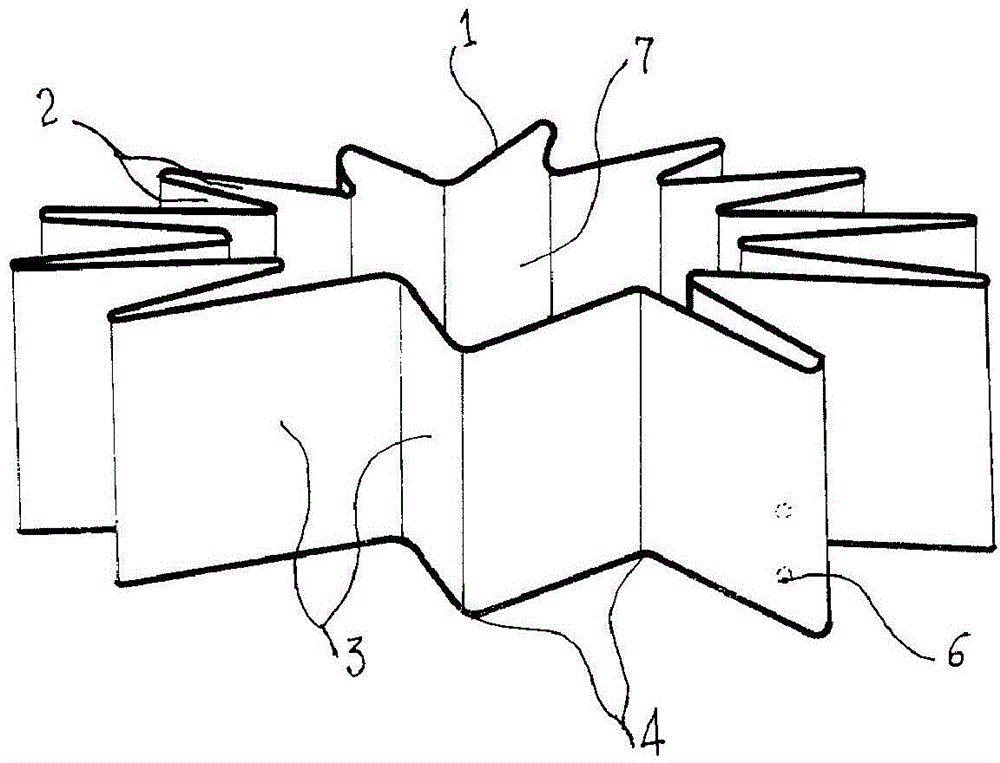

[0026] Such as figure 1 - As shown in 6, the high-efficiency and low-cost LED lamp heat dissipation protection mechanism has a heat transfer material layer 1, and the heat transfer material layer 1 is bent or bent to form a heat dissipation body with heat dissipation intervals 2 and heat transfer walls 3. The heat transfer wall 3 can be placed vertically, horizontally, or obliquely, or the heat transfer material layer 1 is bent or bent to form a wave-like heat transfer wall, a concave-convex heat transfer wall, etc., and the heat dissipation interval formed between adjacent heat transfer walls 1 2 can have three faces, two faces, and the other faces are open.

[0027] The heat transfer material layer 1 can be molded (cast), and the heat transfer material layer is bent to form a heat dissipation body with a heat dissipation interval 2 and a heat transfer wall 3. The heat dissipation interval 2 and the heat transfer wall 3 are formed through the heat transfer material Layer 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com