Spindle sleeve part inner/outer diameter detection equipment

A technology for testing equipment and inner and outer diameters, which is applied in the direction of measuring devices and instruments, can solve the problems that the inner hole, outer circle size, roundness, and taper cannot be tested at the same time, so as to achieve good consistency of test data, fast efficiency, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

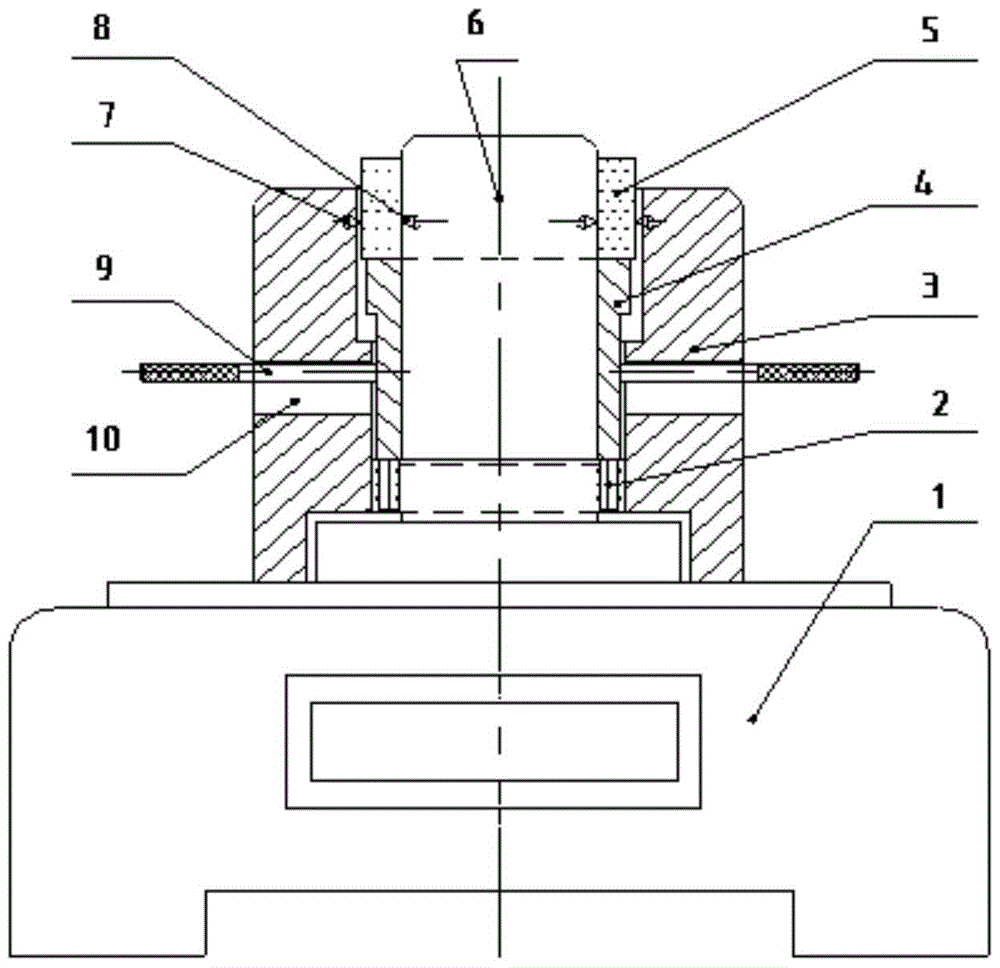

[0017] like figure 1 As shown, the present invention is made up of measuring mechanism and positioning, sliding mechanism, comprises workbench 1, compression spring 2, positioning sleeve 3, sliding sleeve 4, positioning mandrel 6, outer diameter sensor probe 7, inner diameter sensor probe 8, Handle 9 and limit ring groove 10.

[0018] The positioning sleeve 3 and the positioning mandrel 6 are installed on the workbench 1, and the positioning mandrel 6 is arranged at the center of the sliding sleeve 4, which is convenient for installing the product 5 under test. The positioning sleeve 3 is sleeved on the outside of the sliding sleeve 4. The positioning sleeve 3 and the sliding sleeve 4, and the sliding sleeve 4 and the positioning mandrel 6 are clearance fit. The middle part of the sliding sleeve 4 is provided with a handle 9, which is limited by the limit ring groove 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com