Servo-pressure contact device for overlarge current primary current-carrying conductor

A technology of current-carrying conductors and contact devices, which is applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of large differences in test results, inability to simulate the working environment, uneven distribution of magnetic fields, etc., and achieve simple structure and safe operation Reliable, easy access effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

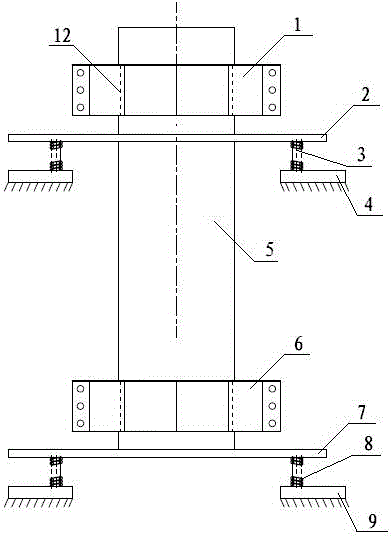

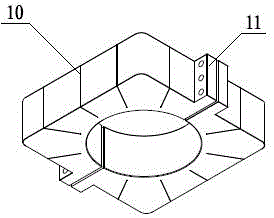

[0016] Such as figure 1 , 2 As shown, the follow-up pressure contact device of the ultra-high current primary current-carrying conductor provided by the present invention, the primary current-carrying conductor 5 is made of a copper rod, the diameter of the copper rod in this embodiment is 200 mm, its own weight is 150 kg, and its length is 1340 mm. The high current is above 40kA, and the duration is above 20 hours. The top of the primary current-carrying conductor is connected to the driving mechanism of the ultra-high current test equipment, and the driving mechanism drives the primary current-carrying conductor to move up and down, so that the ultra-high current transformer with a through-core structure can be put in and taken out. The upper and bottom ends of the primary current-carrying conductor are respectively provided with annular grooves 12, and the hoops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com