Light guide plate and backlight module

A light guide plate and light collection technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems that glass cannot be formed, limit the application of glass light guide plates, and reduce light use efficiency, so as to achieve the effect of improving light utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

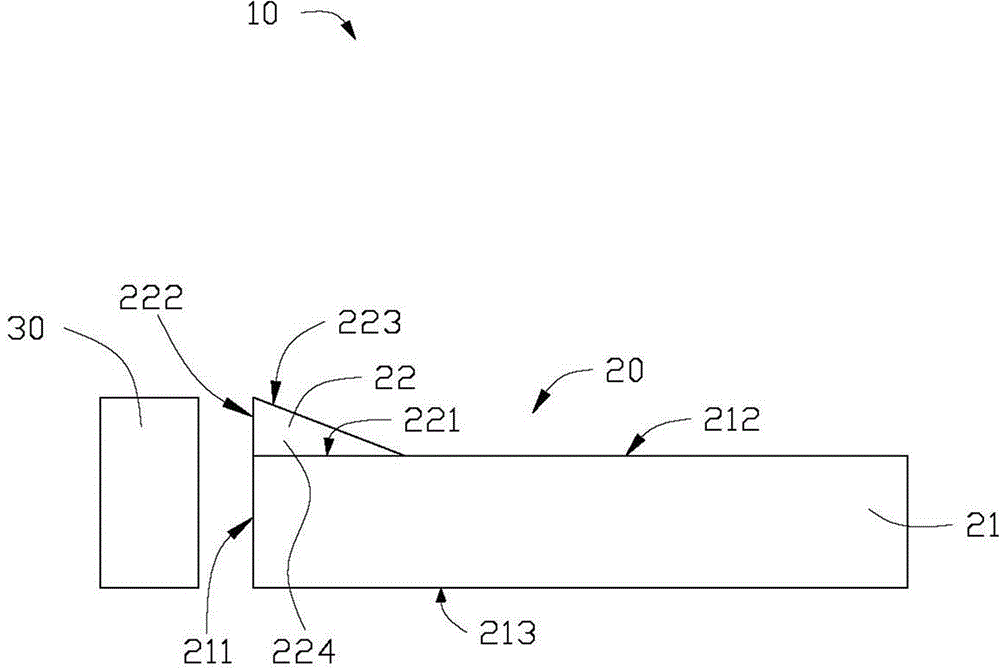

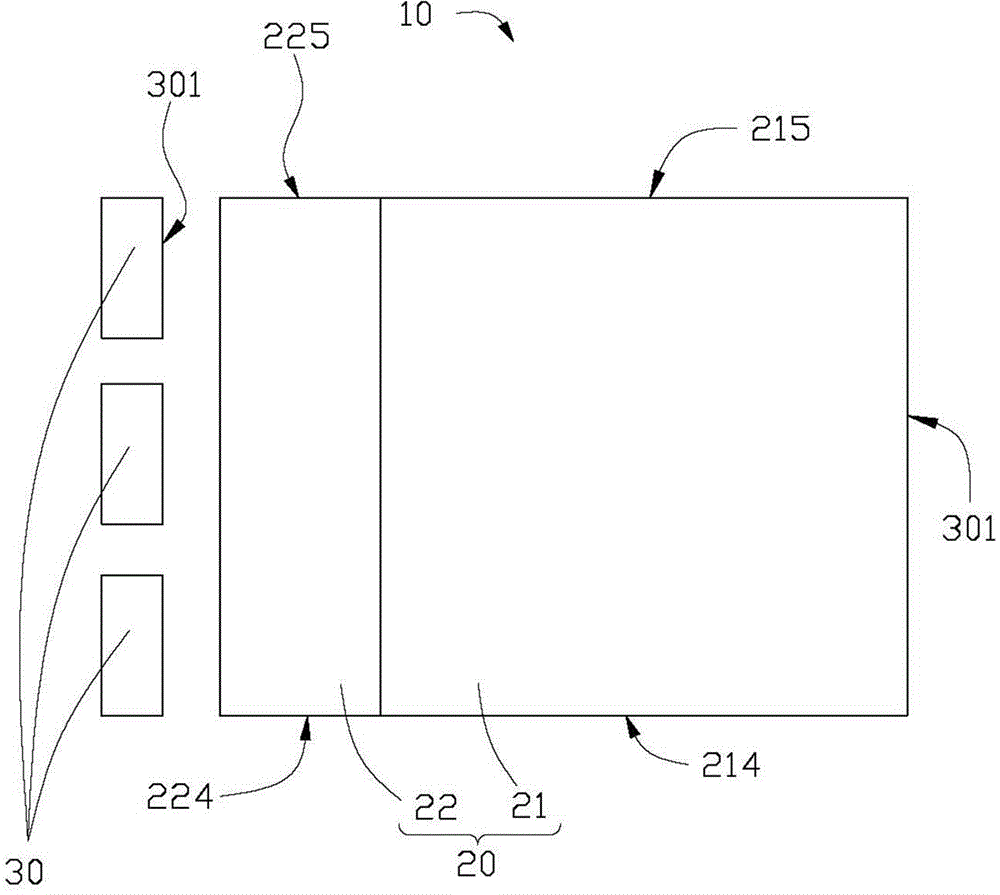

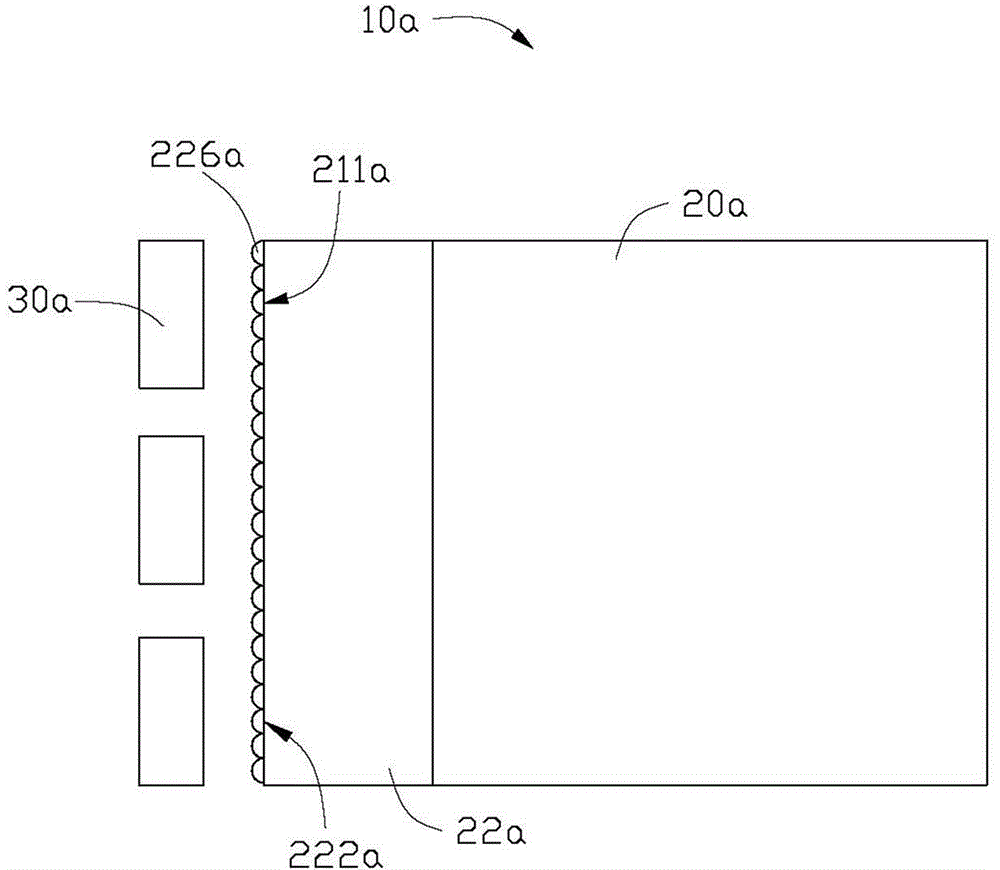

[0018] see figure 1 and figure 2 , the first embodiment of the technical solution provides a backlight module 10 . The backlight module 10 includes a light guide plate 20 and at least one light source 30 .

[0019] The light guide plate 20 includes a light guide body 21 and a light collection structure 22 formed on the light guide body 21 .

[0020] The light guide body 21 can be in the shape of a flat plate or other shapes. In this embodiment, it is in the shape of a flat plate. 212 , the two sides 214 , 215 of the bottom surface 213 . The light emitting surface 212 and the bottom surface 213 are respectively located on opposite sides of the light guide body 21 . The light incident surface 211 is connected between the light exit surface 212 and the bottom surface 213 . The light guide body 21 is made of transparent glass. The reasons for using glass materials are that glass materials have strong thinning ability, high mechanical strength, low absorption rate, wide ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com