Multiangle spectral sensitivity analysis method for film system and application of method

A sensitivity analysis, multi-angle technology, used in optics, optical components, instruments, etc., can solve problems such as aggravating product optical uniformity and optical performance changes, shortening product development cycles, optimizing product performance, and avoiding product debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

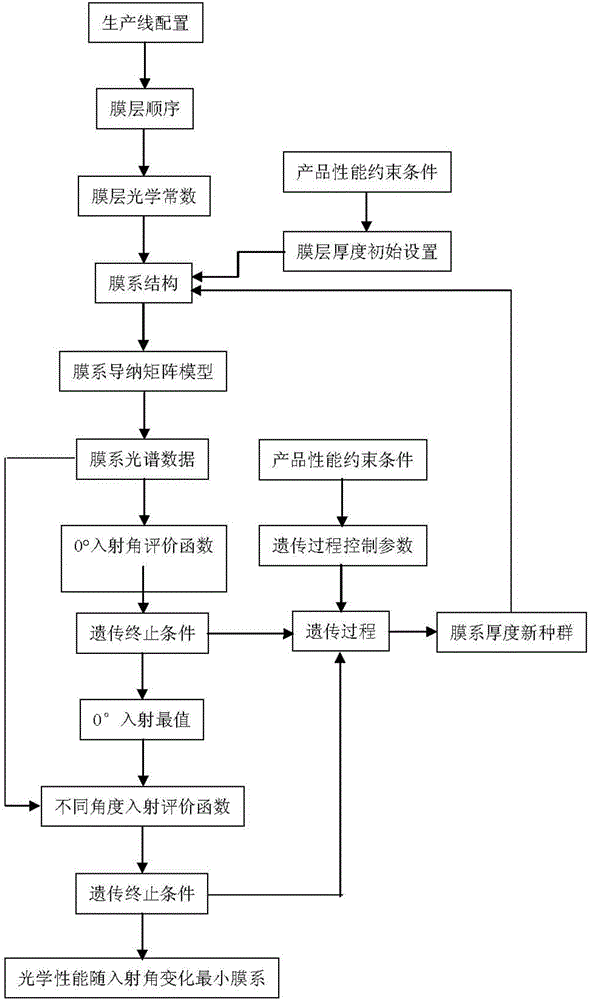

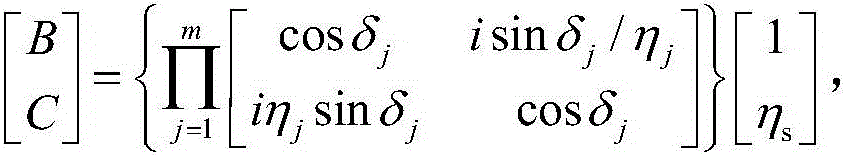

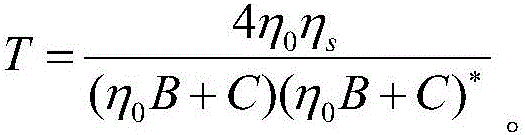

Method used

Image

Examples

Embodiment 1

[0042] Taking magnetron sputtering as an example of a large-area solar selective absorption film, the solar selective absorption film is mainly used for photothermal conversion, and its main goal is to absorb solar energy to the greatest extent and convert it into heat energy, so its main performance is reflected in solar energy. Absorption rate, the greater the solar absorption rate, the better the product performance. Since the absorptivity is not easy to measure directly, and the solar selective absorbing film layer is plated on an aluminum plate, its transmittance is 0. According to the principle of energy conservation, the absorptivity of the product = 1-reflectivity, so if the solar absorptivity of the product Maximum, which corresponds to the minimum solar reflectance. Table 1 shows the target position and material configuration of the production line, and the film layer order determined by it. The substrate is an aluminum plate with a thickness of 1mm; when using magne...

Embodiment 2

[0063] The following uses the antireflection and antireflection coating as an example. The anti-reflection and anti-reflection coating is to increase the transmittance of the substrate and reduce the reflectivity by coating multi-layer films with different optical constants on the surface of the substrate. The substrate can be transparent materials such as glass and resin. The performance of anti-reflection and anti-reflection coatings is mainly aimed at visible light, so the wavelength range of calculation and analysis is 380-780nm in the visible light band. According to the characteristics of performance requirements, the visible light transmittance of the product film system needs to reach the maximum. The present invention uses 3mm borosilicate glass as the substrate, and Table 7 shows the target configuration of the production line and the sequence of the film layers determined. The production conditions prepare a total of 4 layers of anti-reflection and anti-reflection co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com