Mask plate-based secondary exposure method for integrated circuit substrate

An integrated circuit-based, secondary exposure technology, applied in the semiconductor field, can solve the problems of affecting production, reducing the exposure efficiency of laser exposure machines, and consuming a lot of time, so as to achieve the effects of increasing production capacity, accelerating exposure efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the specific details of the present invention described below are only for illustrating the present invention, and do not constitute a limitation to the present invention. Any modifications and variations made in accordance with the teachings of the invention as described are also within the scope of the invention.

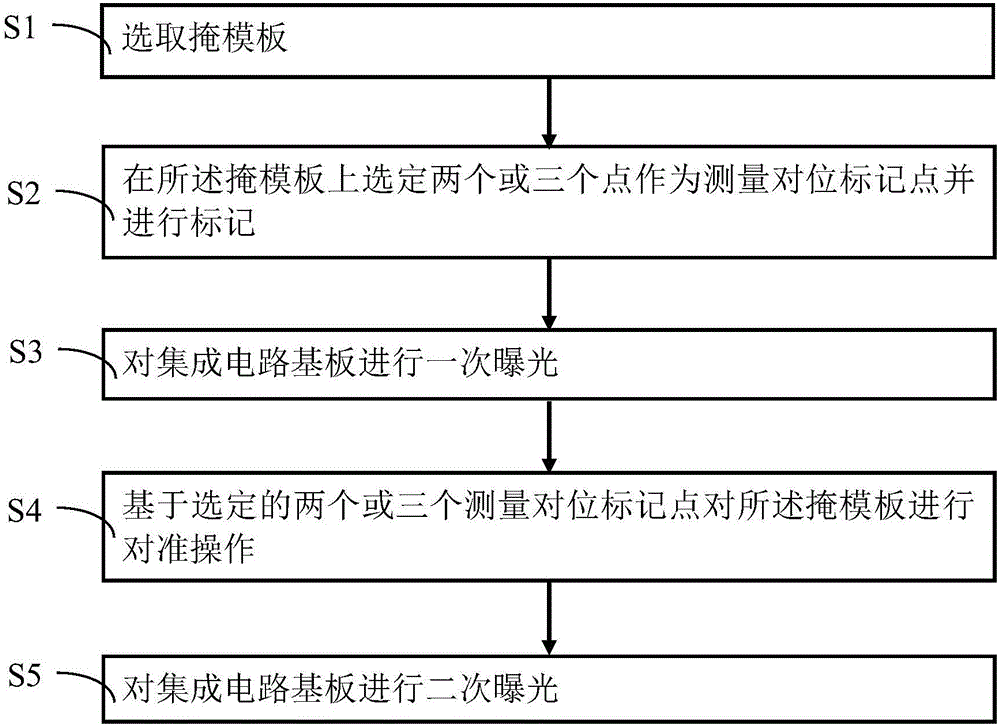

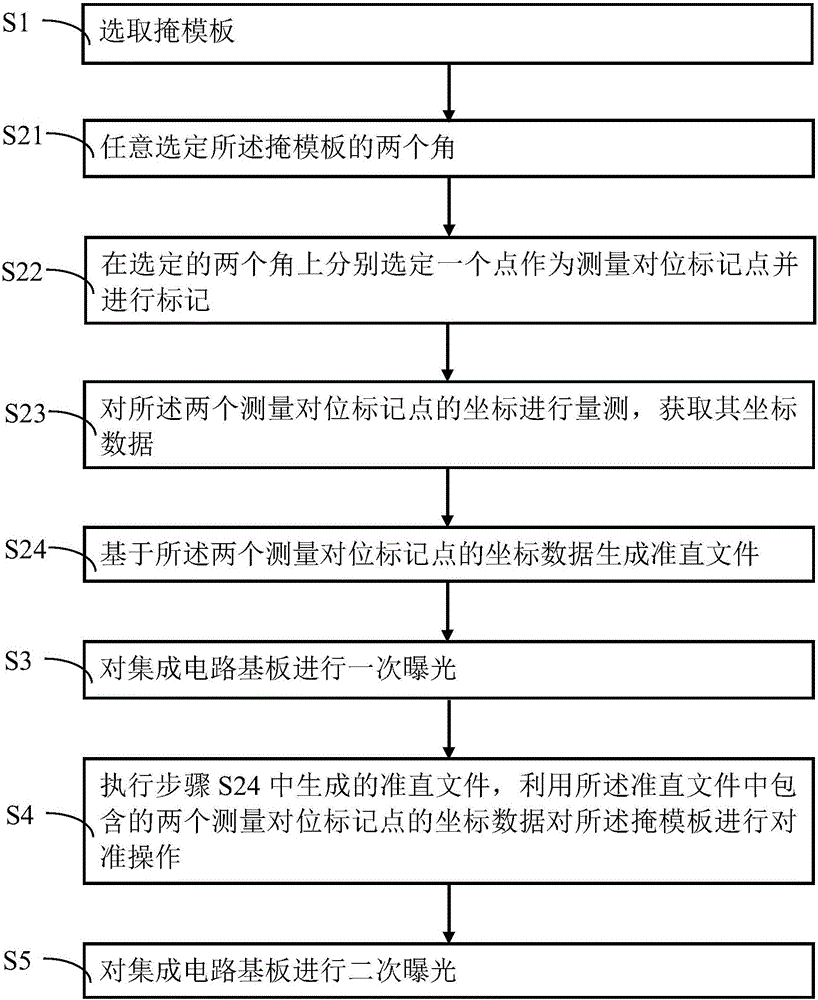

[0040] like figure 1 As shown, it is a schematic flow chart of an embodiment of a mask-based integrated circuit substrate secondary exposure method provided by the present invention. It can be seen from the figure that the integrated circuit substrate secondary exposure method includes: S1 Selecting a mask ; S2 selects two or three points on the mask as the measurement alignment mark points and marks them; S3 exposes the integrated circuit substrate once; S4 aligns the mask based on the selected two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com