Integral type observation cover plate used for semiconductor coating equipment

A kind of coating equipment and integrated technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of air leakage, safety, and hidden dangers in the vacuum system, and achieve the avoidance of safety hazards, reasonable structure, and improved positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

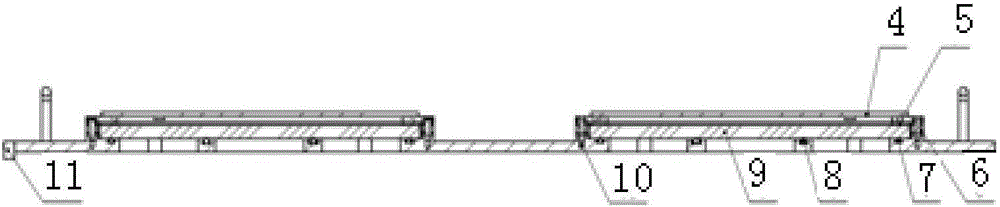

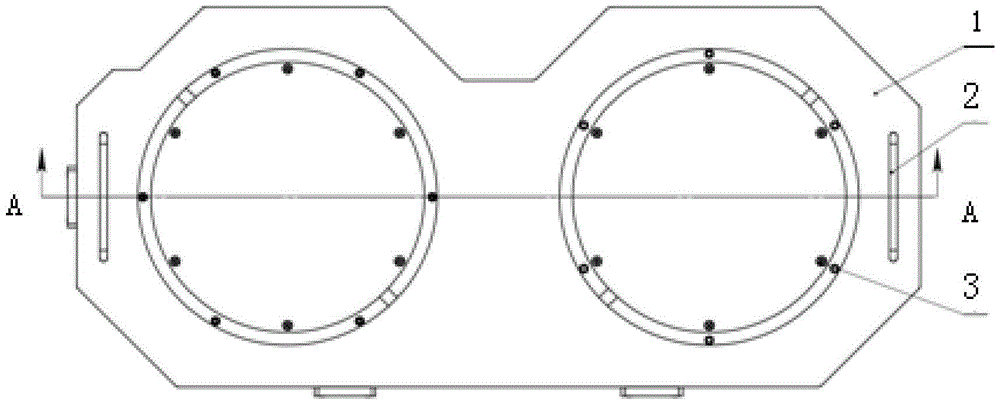

[0013] refer to figure 1 and figure 2 , an integral observation cover plate for semiconductor coating equipment, including a large cover plate 1, a handle 2, flat head screws 3, a plastic protection plate 4, a plastic gasket 5, a metal pressure plate 6, a large sealing ring 7, and a small sealing ring 8 , quartz glass 9, hexagon socket head cap screw 10 and positioning block 11. Sealing ring A7 and sealing ring B8 are respectively embedded in the sealing groove of the above-mentioned large cover plate 1, and a quartz glass 9 is arranged on the end face of the large cover plate 1 embedded in the sealing ring, and a plastic gasket 5 is arranged on the quartz glass 9, and a metal pressing plate 6 Press on the plastic gasket 5, and then tighten the hexagon socket head cap screws 10 diagonally. Then the plastic protection plate 4 is fixed on the top of the metal pressing plate 6 with flat head screws 3 . A handle 2 is arranged on the top of the above-mentioned large cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com