Moving coil type loudspeaker

一种动圈式扬声器、一起的技术,应用在扩音器、传感器、换能器膜片等方向,能够解决影响扬声器、制约扬声器低频性能、扬声器位移监控准确度有限等问题,达到精确检测的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

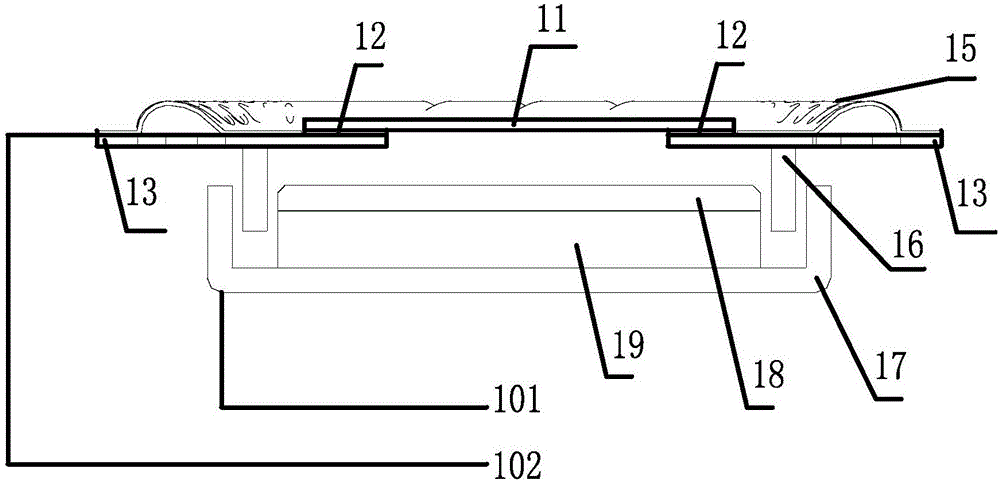

[0040] see figure 1 The structure of the dynamic speaker provided by the first embodiment of the present invention is shown as follows:

[0041] The moving coil loudspeaker includes a vibration system, a magnetic circuit system located below the vibration system, and a housing for accommodating the vibration system and the magnetic circuit system.

[0042] The vibration system includes a diaphragm, a damper 13 , and a voice coil 16 combined from top to bottom. The diaphragm includes a diaphragm body part 15 with a ring and a diaphragm reinforcing part 11 combined at the center below the diaphragm body part 15 . The center of the damper 13 is a hollow structure, and the edge of the damper 13 is fixed to the housing. Wherein, the diaphragm reinforcement part 11 includes a first conductive material layer, the damper 13 includes a second conductive material layer, and the diaphragm reinforcement part 11 and the spider 13 are bonded by a conductive adhesive 12, And the conductiv...

Embodiment 2

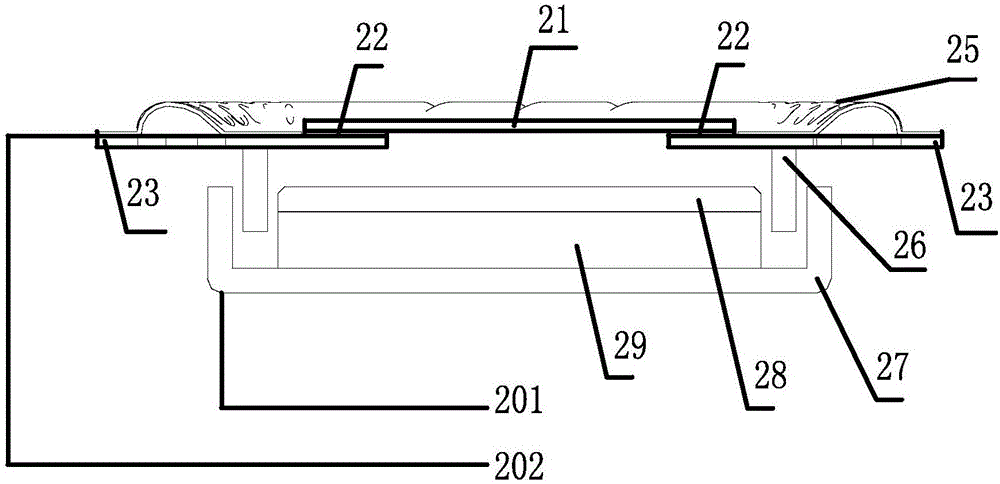

[0052] see figure 2 The structure of the dynamic speaker provided by the second embodiment of the present invention is illustrated as follows:

[0053] The moving coil loudspeaker includes a vibration system, a magnetic circuit system located below the vibration system, and a housing for accommodating the vibration system and the magnetic circuit system.

[0054] The vibration system includes a diaphragm, a damper 23 , and a voice coil 26 combined from top to bottom. The diaphragm includes a diaphragm body part 25 with a ring and a diaphragm reinforcing part 21 combined at a central position below the diaphragm body part 25 . The center of the damper 23 is a hollow structure, and the edge of the damper 23 is fixed with the housing. Wherein, the diaphragm reinforcing part 21 includes a first conductive material layer, and the damper 23 includes a second conductive material layer, and the diaphragm reinforcing part 21 and the spider 23 are bonded by an insulating adhesive 22 ...

Embodiment 3

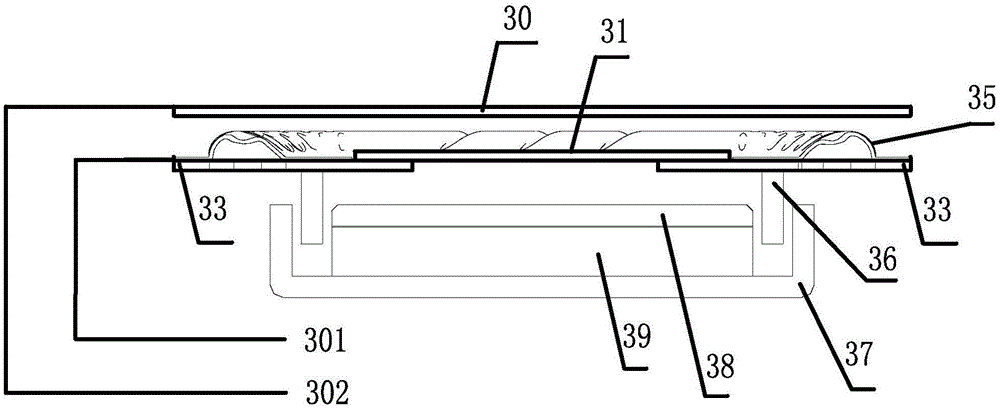

[0063] see image 3 The structure of the dynamic speaker provided by the third embodiment of the present invention is illustrated as follows:

[0064] The moving coil speaker includes a front cover, a vibration system, and a magnetic circuit system from top to bottom, and the moving coil speaker also includes a housing combined with the front cover.

[0065] The vibration system includes a diaphragm, a damper 33 , and a voice coil 36 combined from top to bottom. The diaphragm includes a diaphragm body part 35 with a ring and a diaphragm reinforcing part 31 combined at a central position below the diaphragm body part 35 . The center of the damper 33 is a hollow structure, and the edge of the damper 33 is fixed with the housing. Wherein, the diaphragm reinforcing part 31 includes a first conductive material layer, the damper 33 includes a second conductive material layer, and the diaphragm reinforcing part 31 and the damper 33 are bonded together. Preferably, the whole diaphr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com