Circuit board outer box with water-proof and dust-proof functions

A waterproof and dustproof, circuit board technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, chassis/cabinet/drawer parts, etc. Affecting heat dissipation performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

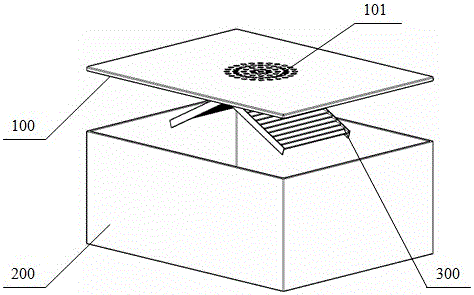

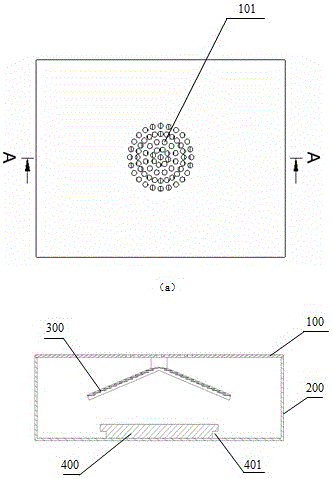

[0013] The invention provides a circuit board outer box with waterproof and dustproof functions. In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

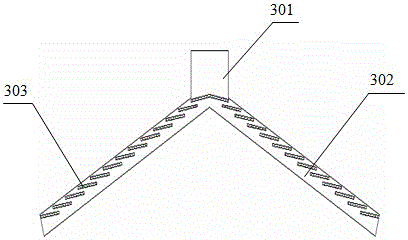

[0014] See attached figure 1 , attached figure 2 And attached image 3 , a circuit board outer box with waterproof and dustproof functions, including a box cover 100, a box body 200, the box cover 100 is provided with a heat dissipation mesh 101, and also includes a protective shed 300, the protective shed 300 is connected by a connecting end 301 , a frame 302 and water-retaining and dust-proof blades 303; the connection end 301 is connected to the top of the frame 302, the water-retaining and dust-proof blades 303 are fixed inside the frame 302, and the water-retaining and dust-proof blades 303 are equidistantly distributed in parallel inside the frame 302, and Adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com