Cap opener and operating method thereof

A technology of cap opener and bottle cap, which is applied in the disassembly of threaded caps and finger-shaped hooks, etc. It can solve the problems of time-consuming and labor-intensive opening of medicine bottles, experimental safety accidents, and affecting mentality, so as to improve the safety of use, Improve test efficiency and solve time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

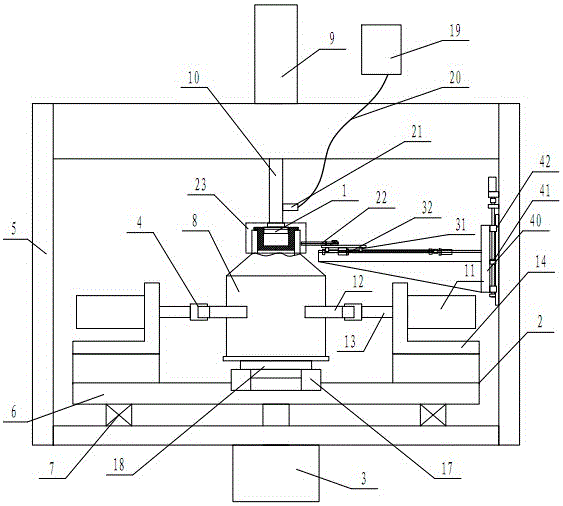

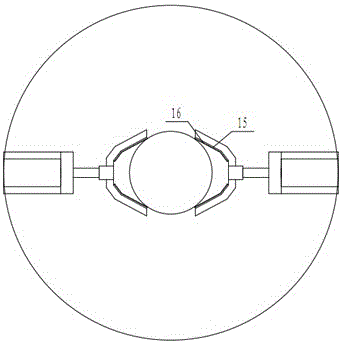

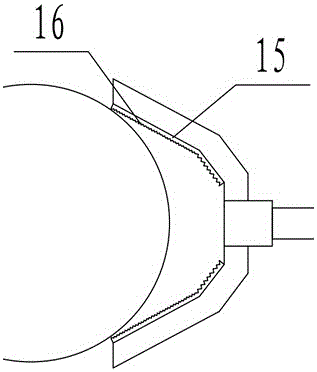

[0034] Embodiment 1: as Figure 1-Figure 7 As shown, a cap opener includes a bottle cap clamping mechanism 22 that can move up and down and a rotating and fixing mechanism 2. The rotating and fixing mechanism 2 includes a drive motor 3 and a clamping mechanism 4. The drive motor 3 is fixedly connected to the bottom of the support frame 5 , its output shaft is fixedly connected to the rotating support plate 6, a rotating guide rail 7 coaxial with the output shaft of the drive motor 3 is provided under the support plate 6, and a clamping mechanism 4 for clamping a medicine bottle 8 is installed on its upper surface, and the bottle Cap clamping mechanism 22 is installed on bottle cap 23 one side, is used for fixing bottle cap 22, and the rotation linkage with driving motor 3 when moving upwards, promptly driving motor 3 rotates a circle, and bottle cap clamping mechanism 22 moves upwards a pitch.

[0035] Preferably, the above-mentioned lid opener also includes a vacuum suction c...

Embodiment 2

[0044] Embodiment 2: a kind of operation method of cap opener, this method comprises the following steps:

[0045] (1) Place the medicine bottle on the placement table;

[0046] (2) Start the lead screw drive motor, drive the slide plate to move to a suitable position, and start the hydraulic cylinder three, so that the cylinder rod three of the hydraulic cylinder three drives the movable clamping piece of the bottle cap clamping mechanism to realize the clamping of the bottle cap;

[0047] (3) Start the two hydraulic cylinders of the clamping and fixing mechanism to clamp and fix the medicine bottle;

[0048] (4) After clamping and fixing, start the drive motor and the longitudinal screw drive motor to rotate the support plate and move the bottle cap upward. After the support plate rotates, the bottle cap will turn out from the bottle mouth under the condition of relative movement, and stop the hydraulic cylinder three. , the screw drive motor drives the screw nut to retract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com