Noise reduction structure for blade of wind turbine generator

A technology of wind turbines and blades, which is applied in the field of noise reduction design of blade tips of wind turbines, and can solve problems affecting the normal life of residents, excessive noise, and obstacles to the development and utilization of wind resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

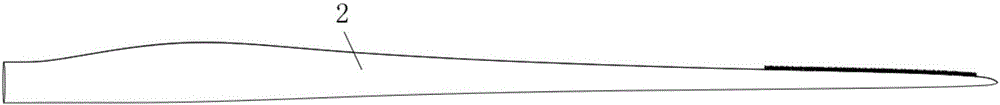

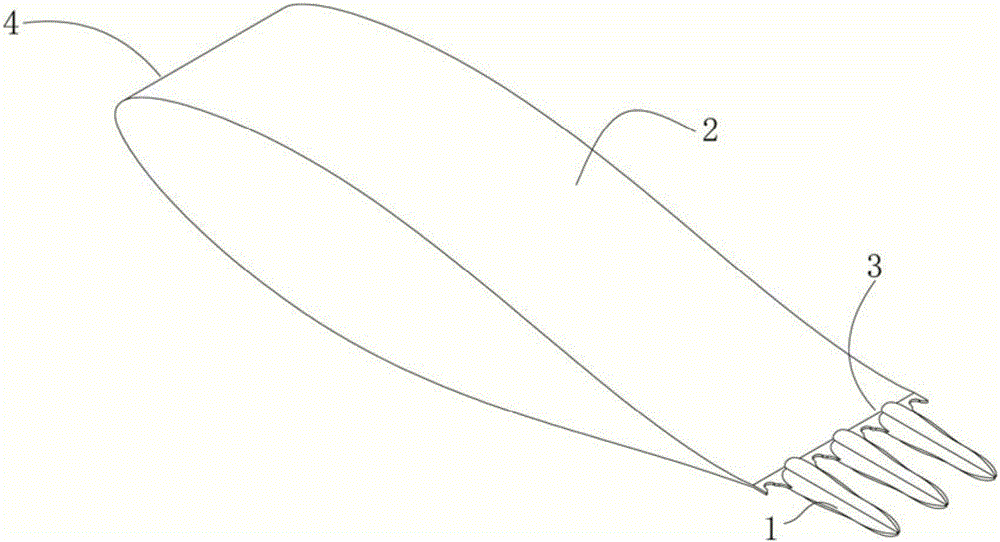

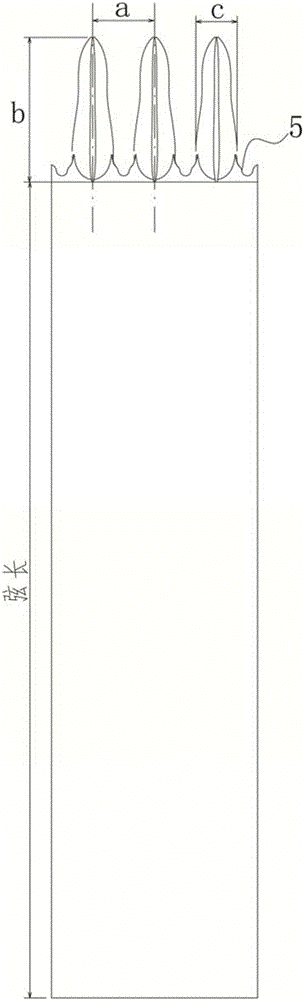

[0025] Such as Figure 1 to Figure 5 As shown, the noise reduction structure of the wind turbine blade described in this embodiment includes a plurality of cross-shaped noise reduction parts 1, and the plurality of cross-shaped noise reduction parts 1 are evenly distributed in the 75%-95% span of the blade 2. % on the trailing edge 3 corresponding to the position or on all the trailing edges 3 of the blade, the leading edge 4 of the blade remains unchanged, and the arrangement distance a of two cross-shaped noise-reducing parts 1 (that is, two adjacent cross-shaped noise-reducing parts 1 in each The distance between the centerlines in the length direction) is 40%-50% of the length b of the cross-shaped noise reduction piece, and each cross-shaped noise reduction piece 1 is composed of two orthogonal gourd-like flat pieces, and the two flat pieces The lengths of the flat parts are completely overlapped, and the narrow end of the flat part faces outwards, its cross-section is el...

Embodiment 2

[0029] Different from Embodiment 1, the flat piece described in this embodiment is distributed with spherical protrusions (such as Figure 6 shown).

Embodiment 3

[0031] The difference from Embodiment 1 is that the flat piece described in this embodiment is distributed with cylindrical protrusions (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com