Concentrated feed additives and preparation technology thereof

A technology for concentrated feed and additives, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve the problems of increased cost, unsuitable for large-scale use, animal indigestion, etc., and achieve good palatability and nutritional value. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 2

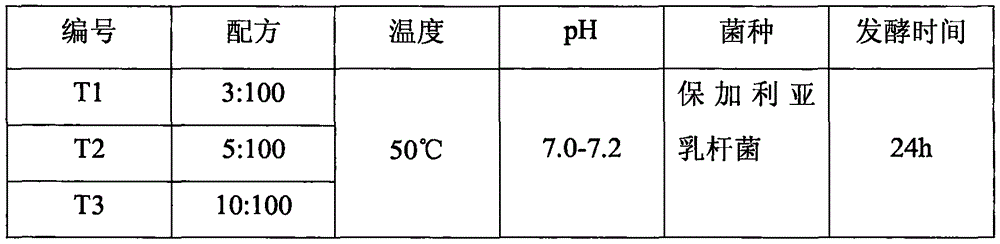

[0018] Implementation 2 Preparation of Concentrated Feed Additives

[0019] Get 3 grams of Astragalus membranaceus and 100 grams of crucian carp powder (weight ratio 3:100), mix them evenly, grind them into powder, pass through a 200-mesh sieve, and autoclave for later use;

[0020] The sterilized mixed material is placed in an anaerobic fermentation tank, the temperature is adjusted to 50° C. and the pH value is 7.0, and Lactobacillus bulgaricus is implanted, and fermented at a constant temperature for 24 hours.

Embodiment 3

[0021] Implementation 3 Preparation of Concentrated Feed Additives

[0022] Get 5 grams of Radix Astragali and 100 grams of crucian carp powder (weight ratio 5:100), mix them evenly, grind them into powder, pass through a 200-mesh sieve, and autoclave for later use;

[0023] The sterilized mixed material is placed in an anaerobic fermentation tank, the temperature is adjusted to 60° C. and the pH value is 7.2, and Lactobacillus bulgaricus is implanted, and fermented at a constant temperature for 48 hours.

Embodiment 4

[0024] Implementation 4 Preparation of Concentrated Feed Additives

[0025] Get 10 grams of Astragalus membranaceus and 100 grams of crucian carp powder (weight ratio 10:100), mix them evenly, grind them into powder, pass through a 200-mesh sieve, and autoclave for later use;

[0026] The sterilized mixed material is placed in an anaerobic fermenter, adjusted to a temperature of 55° C. and a pH of 8.0, implanted with Lactobacillus bulgaricus, and fermented at a constant temperature for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com