Hyaluronic acid oral care film, preparation method and application

A technology of hyaluronic acid and oral care, which is applied in the preparation of hyaluronic acid oral care film and the field of hyaluronic acid oral care film, can solve the problems of unfavorable promotion and single function, and achieves improved use safety, high safety, The effect of improving joint function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiment:

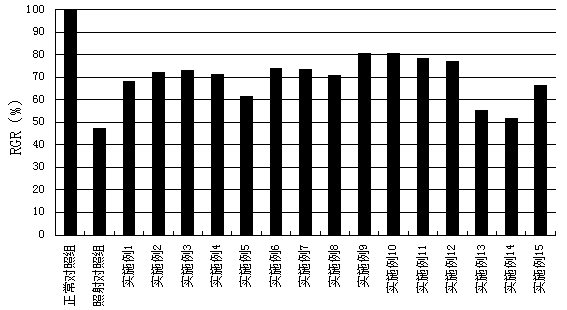

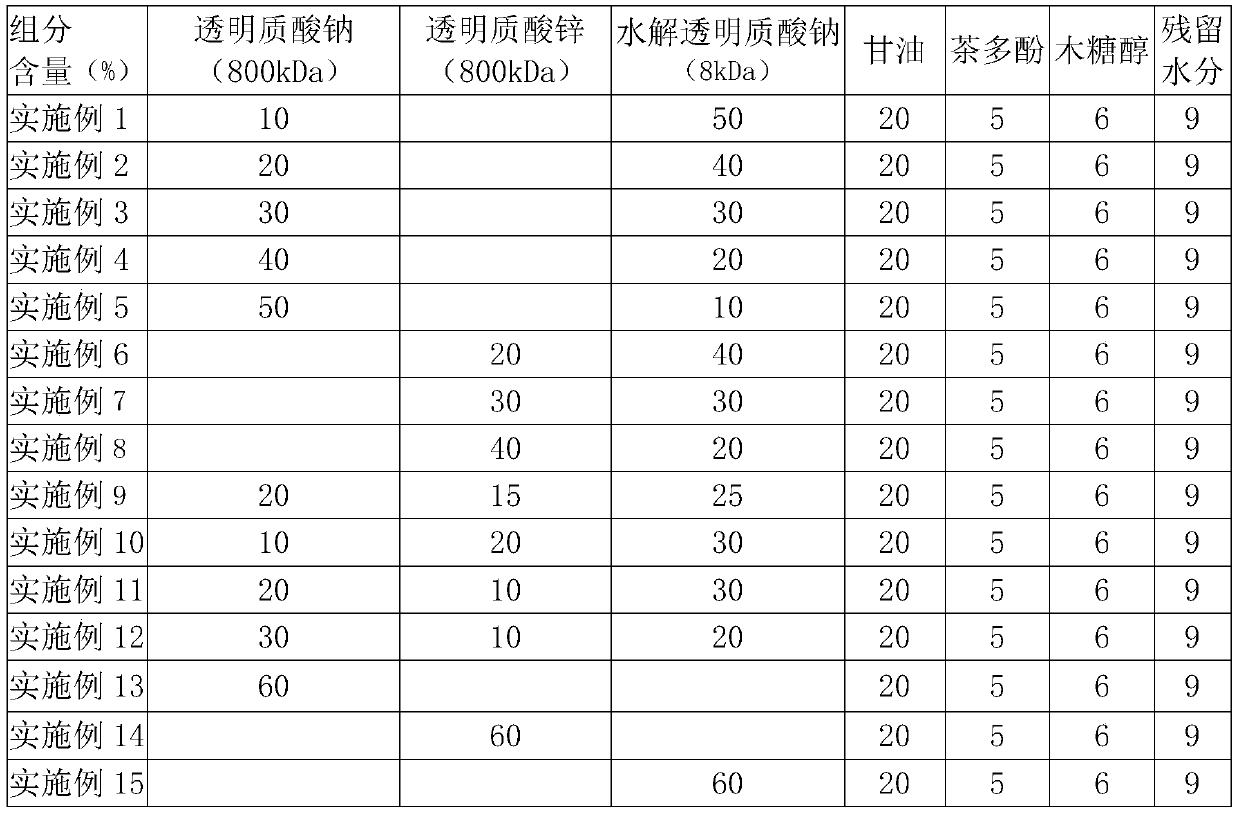

[0038] 1. Embodiment formula is formed

[0039]

[0040] Note: The values in the table are the weight percentages of each component in the dry film.

[0041] 2. the preparation technology of embodiment:

[0042]Each embodiment prepares 100g solution respectively. First add sodium hyaluronate and (or) zinc hyaluronate, and hydrolyzed sodium hyaluronate into a corresponding amount of water, heat to 60-65°C under stirring, and continue stirring to fully dissolve. Then, add the rest of the ingredients, stir to dissolve and mix evenly, then spread it on a stainless steel plate with a thickness of 0.3mm, and dry it at 45-50°C to form a film (the residual moisture in the dry film is controlled to be 9%).

[0043] 3. Membrane Mechanical Properties Test

[0044] Method: Use a universal material testing machine to perform a tensile test on the samples of each example. The fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com