Automatic reciprocating spraying device

A spraying device, a reciprocating technology, applied to the spraying device and other directions, can solve the problems such as the inability to guarantee the uniformity and stability of the coating on the surface of the workpiece, the difficulty in installation and debugging, and the complex structure, and achieve economical and movement accuracy. and easy maintenance, flexible and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

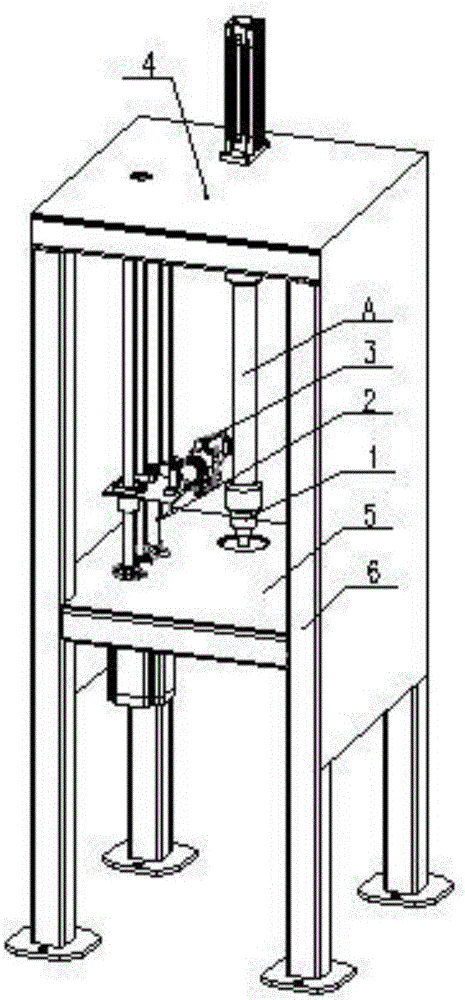

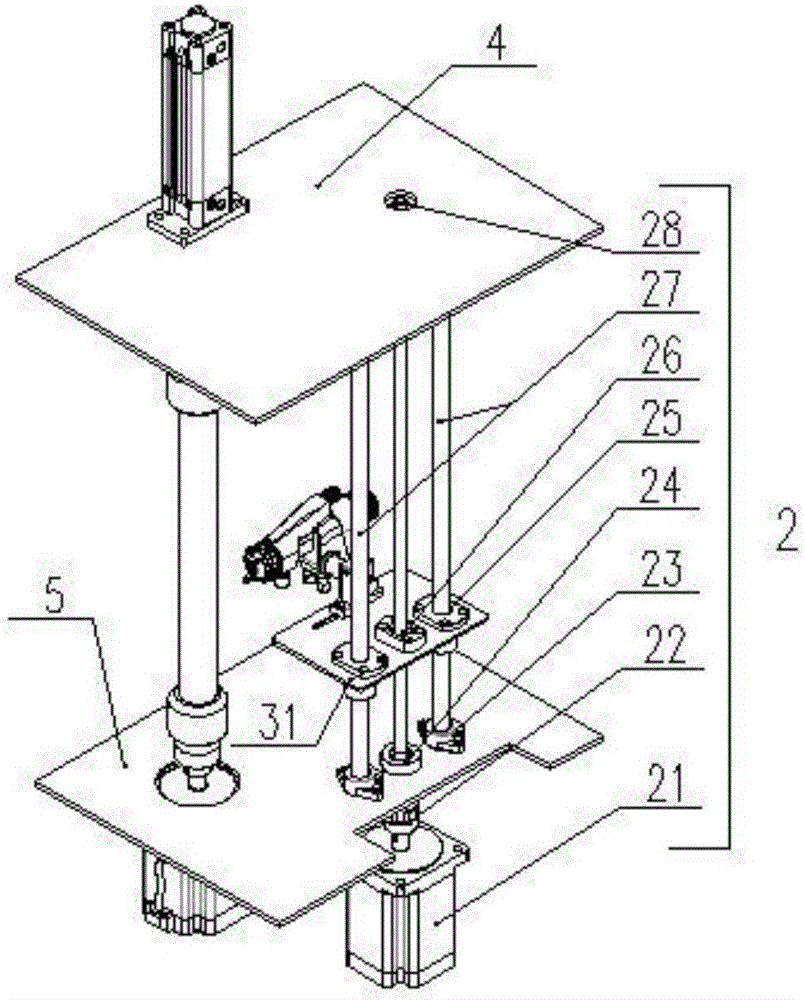

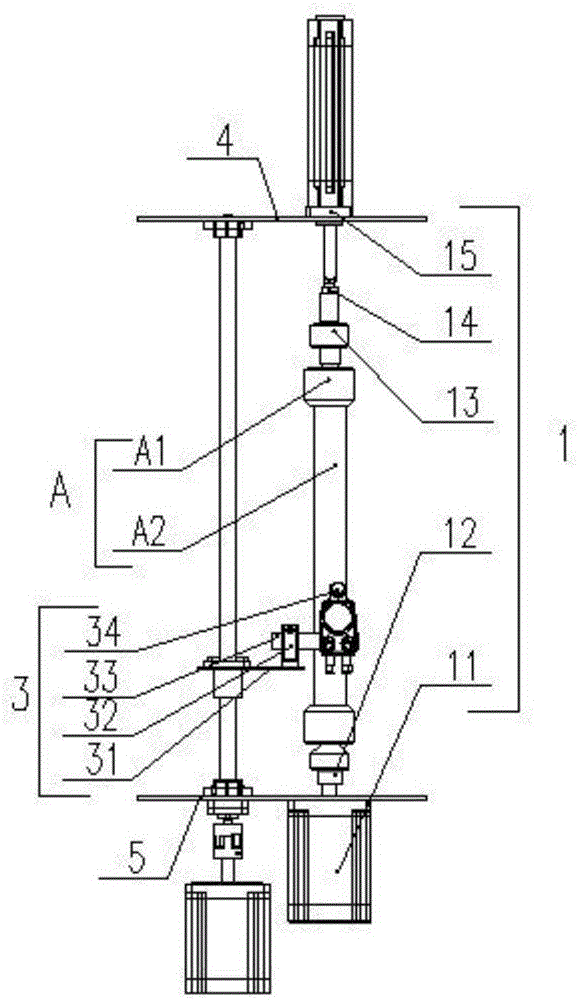

[0027] The specific process of the present invention will now be described through the following embodiments in conjunction with the accompanying drawings.

[0028] As shown in the drawings, an automatic reciprocating spraying device of the present invention includes a frame 6, an upper mounting plate 4, a lower mounting plate 5, a spraying workpiece assembly A, a clamping and rotating unit 1, a spraying adjustment unit 3 and a reciprocating unit 2. Frame 6 is welded by twelve square tubes, four base plates and steel plates on both sides; The spraying workpiece assembly A includes a protective cover A1 and a workpiece A2, and the two protective covers A2 are installed at both ends of the workpiece A1 to protect the two ends of the workpiece A1 from being sprayed.

[0029] The clamping and rotating motion unit 1 includes a No. 1 stepper motor 11, a fixed lower center 12, a rotatable upper center 13, a locknut 14 and a clamping cylinder 15; the No. 1 stepper motor 11 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com