Synchronous driving type rectangular coordinate robot

A Cartesian coordinate and synchronous drive technology, applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of increased failure rate, slow dynamic response, large system inertia, etc., to achieve reduced failure rate, fast dynamic response, and institutional inertia low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

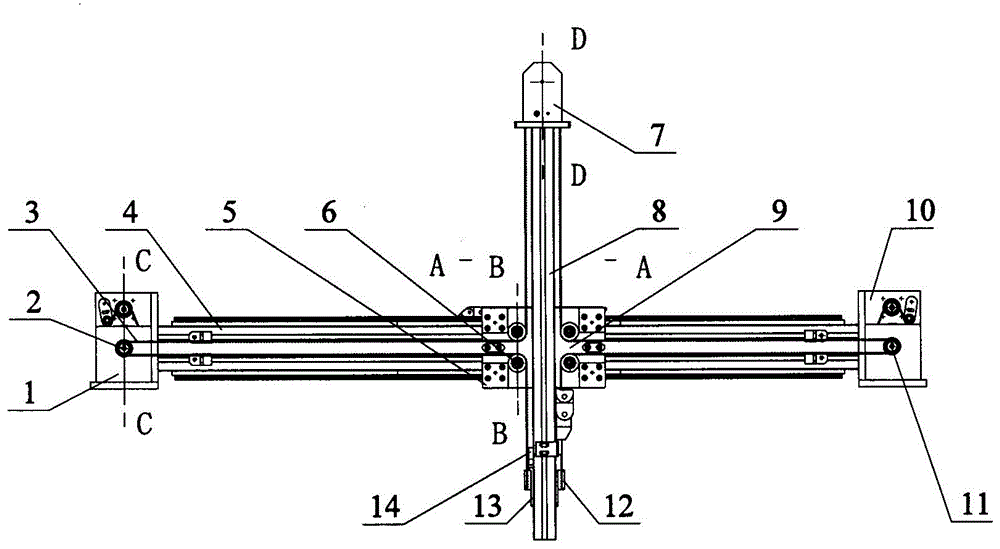

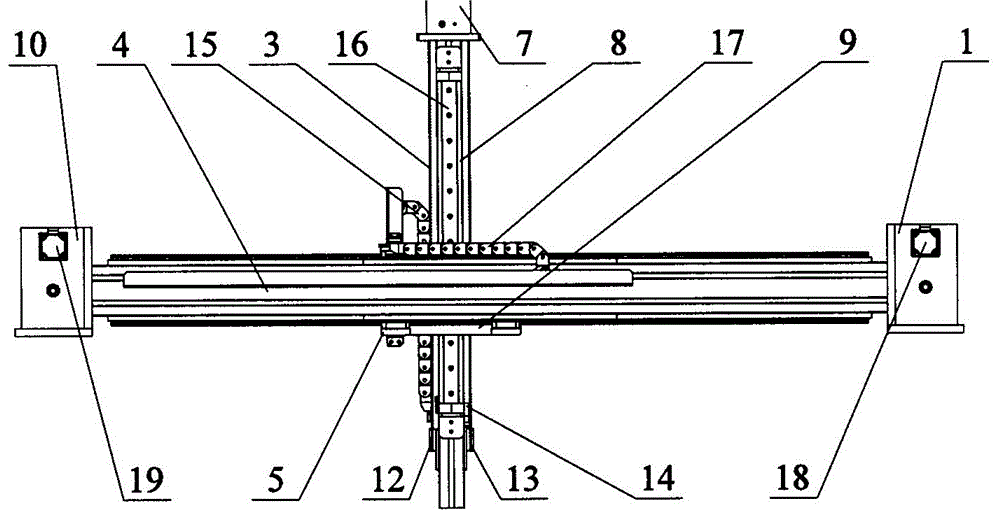

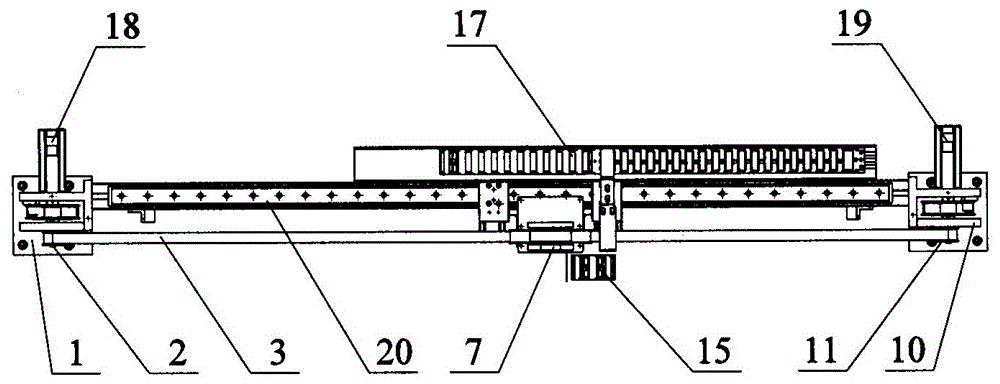

[0027] according to Figure 1-7 The specific structure of the present invention will be described in detail. The synchronously driven rectangular coordinate robot includes a transverse frame main body, a transverse sliding base, a longitudinal main body and a driving mechanism. The transverse fixed beam 4 of the transverse frame main body is connected to the longitudinal base beam 8 of the longitudinal main body through the linkage slide plate 9 of the transverse sliding base, forming mutually perpendicularly distributed transverse movement axes and longitudinal movement axes driven by the same drive mechanism.

[0028] The driving mechanism includes a first transmission assembly 1 and a second transmission assembly 10 with the same structure assembled at both ends of the transverse fixed beam 4 , a longitudinal transmission assembly 7 on the longitudinal base beam 8 and an open-loop transmission timing belt 3 and other components. The open-loop transmission synchronous belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com