A CNC milling tenon machine system and its operating method

An operation method and numerical control milling technology, applied in tenon making device, electrical program control, making tongue or tongue and groove, etc., can solve the problems of high labor cost and long time, and achieve the improvement of processing efficiency, simple operation and system structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

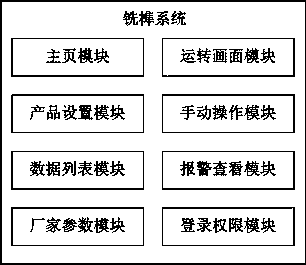

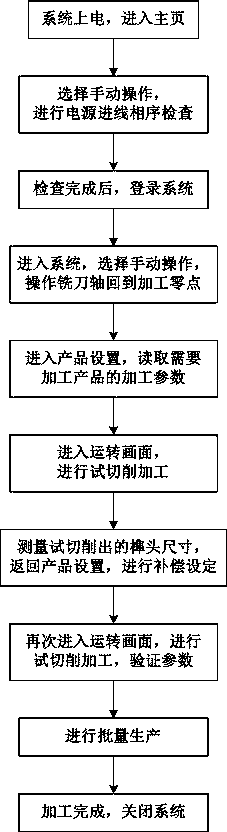

[0036] Such as figure 1 As shown, a CNC milling and tenoning machine system, which includes a homepage module, a product setting module, a running screen module, a manual operation module, a data list module, an alarm viewing module, a manufacturer parameter module and a login authority module;

[0037] The home page module provides date and time display, and provides buttons for entering the product setting module, operation screen module, manual operation module, data list module, alarm viewing module, manufacturer parameter module and login authority module;

[0038] The product setting module provides various parameter settings of products to be processed;

[0039] The operation screen module displays the operation screen of milling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com