A core-pulling mechanism and core-pulling method for a plastic trash can mold lid

A technology of core-pulling mechanism and trash can, which is applied in household appliances, other household appliances, household components, etc., can solve the problems of little improvement in production efficiency, and achieve the effects of compact structure, convenient demoulding, and reasonable mechanism layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

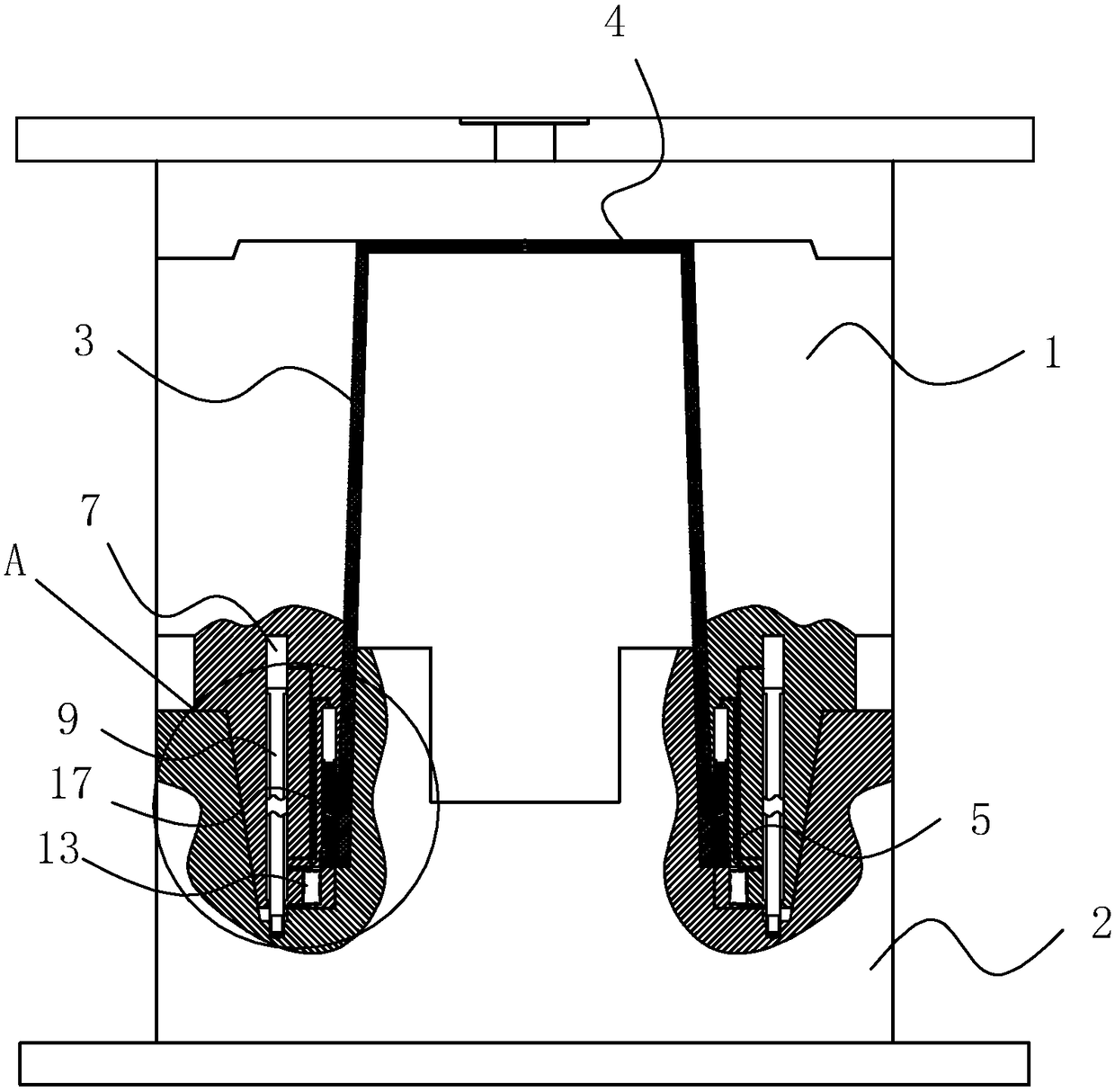

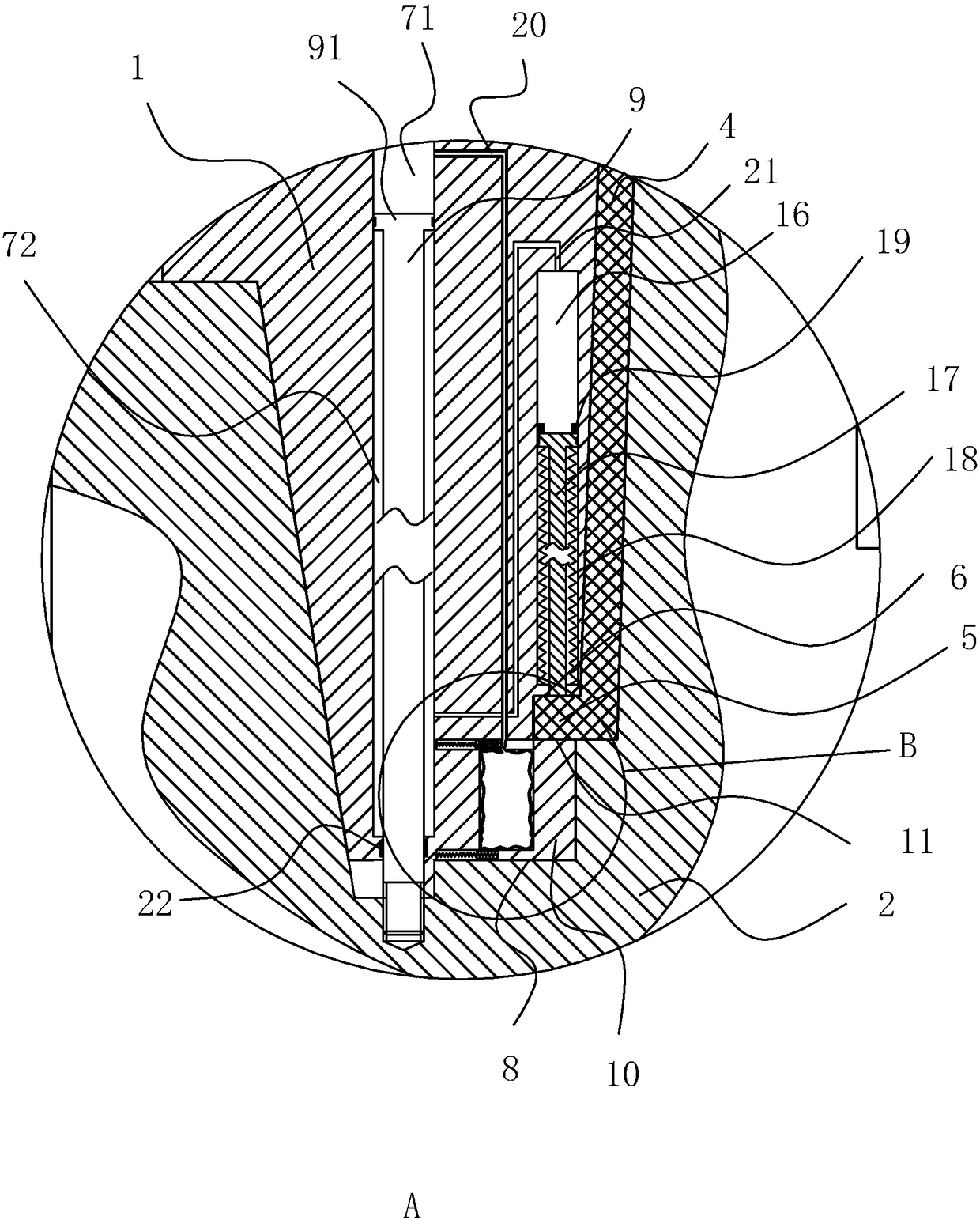

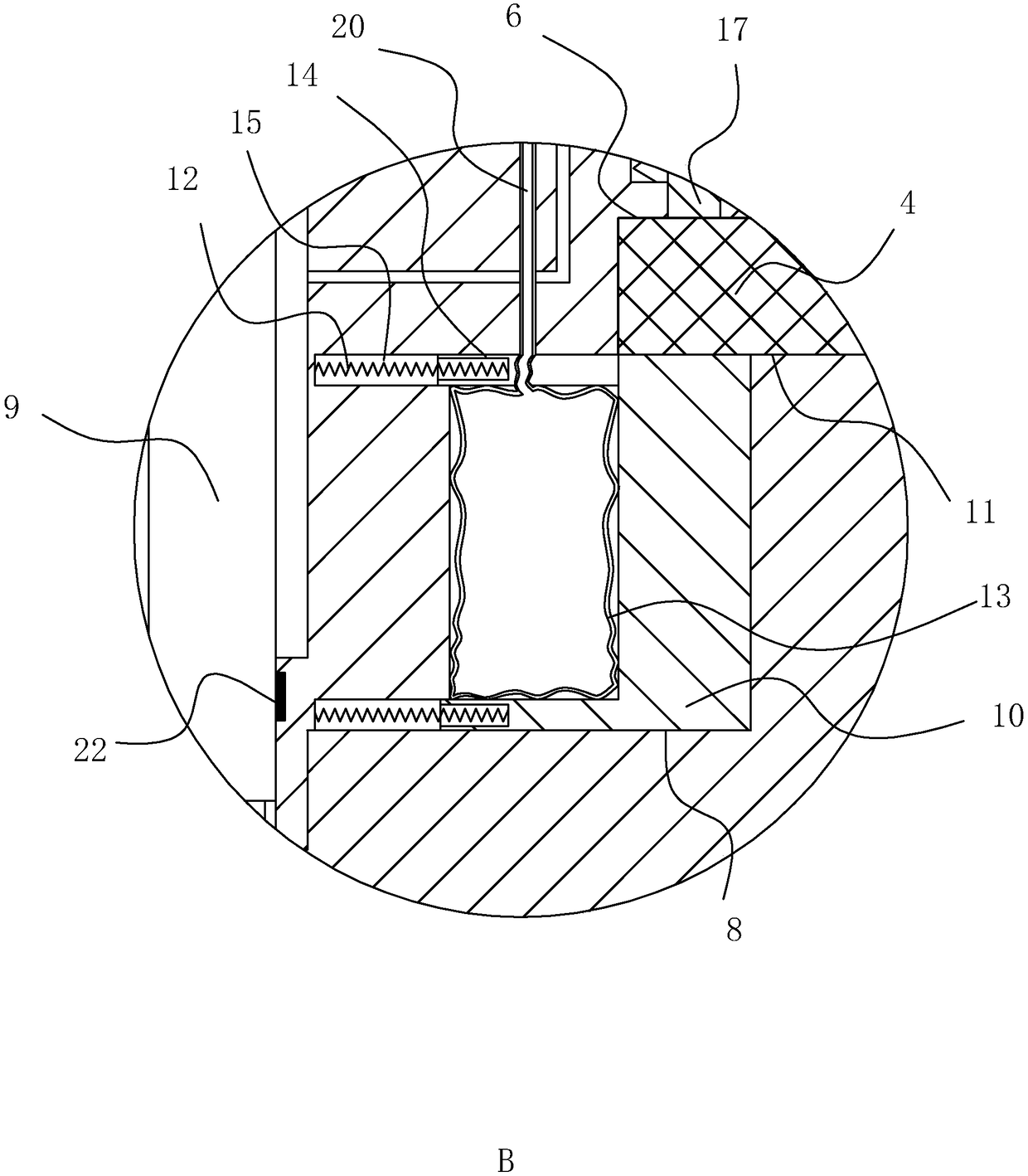

[0048] see figure 1 as well as figure 2 As shown, a core-pulling mechanism for a plastic trash can 4 mold lid includes a fixed mold 1 and a movable mold 2, and the fixed mold 1 and the movable mold 2 will separate from each other or move closer to each other. In this state, a mold cavity 3 is formed between the fixed mold part 1 and the movable mold part 2. After the molten injection molding solution is injected into the mold cavity 3, a garbage can 4 will be formed in the mold cavity 3, and the garbage after molding The mouth of the barrel 4 faces the side of the movable module 2, and the mouth of the molded trash can 4 is provided with a mouth baffle 5, which is a flanging, and the mouth baffle 5 is folded in the direction Towards the outside of the trash can 4, the mold cavity 3 on one side of the fixed mold part 1 is provided with a first forming surface 6 for forming the mouth baffle 5 close to the side of the trash can 4 barrel body, between the fixed mold part 1 and t...

Embodiment 2

[0059] A kind of core-pulling method of plastic trash can 4 mold bung core-pulling mechanism as described in embodiment one, comprises the following steps:

[0060] S1: Driven by external power, and make the fixed mold part 1 and the movable mold part 2 close to each other;

[0061] S2: The movable module 2 pushes the piston rod 9 to move upward along the piston cavity 7, the volume of the upper plug cavity 71 gradually becomes smaller, and the gas in the upper plug cavity 71 is squeezed into the expansion air bag 13 through the expansion air channel 20, The inflatable air bag 13 is extruded to form the block 10 and overcomes the pulling force of the first tension spring 12, so that the second forming surface 11 on the forming block 10 is moved to the side where the mouth baffle 5 is away from the trash can 4 body;

[0062] At the same time of step S2, the volume of the lower plug chamber 72 gradually increases, the gas in the thrust chamber 16 will be drawn into the lower plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com