Double heating device for jet printing machine adopting micro-piezoelectricity printing head

A technology of secondary heating and jet printer, applied in printing and other directions, can solve the problems of poor printing effect, poor thermal conductivity, nozzle temperature loss, etc., and achieve the effect of improving printing quality, good heating effect and low temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

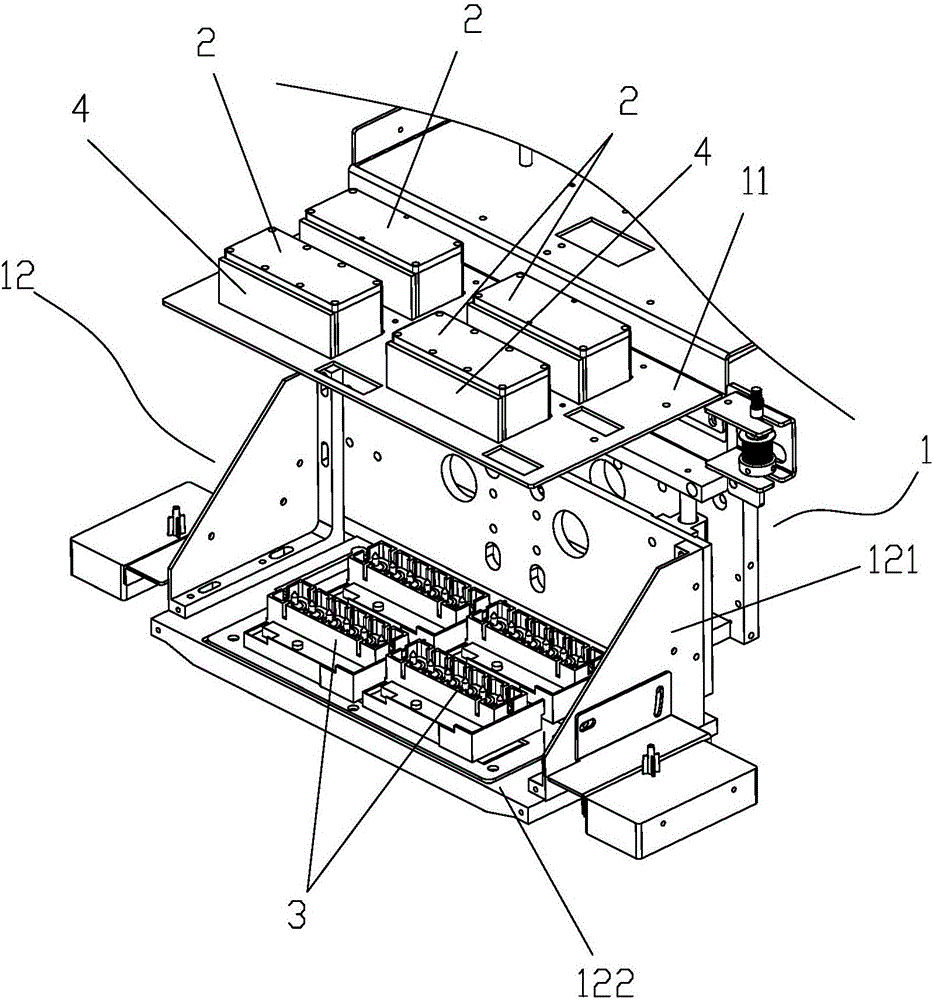

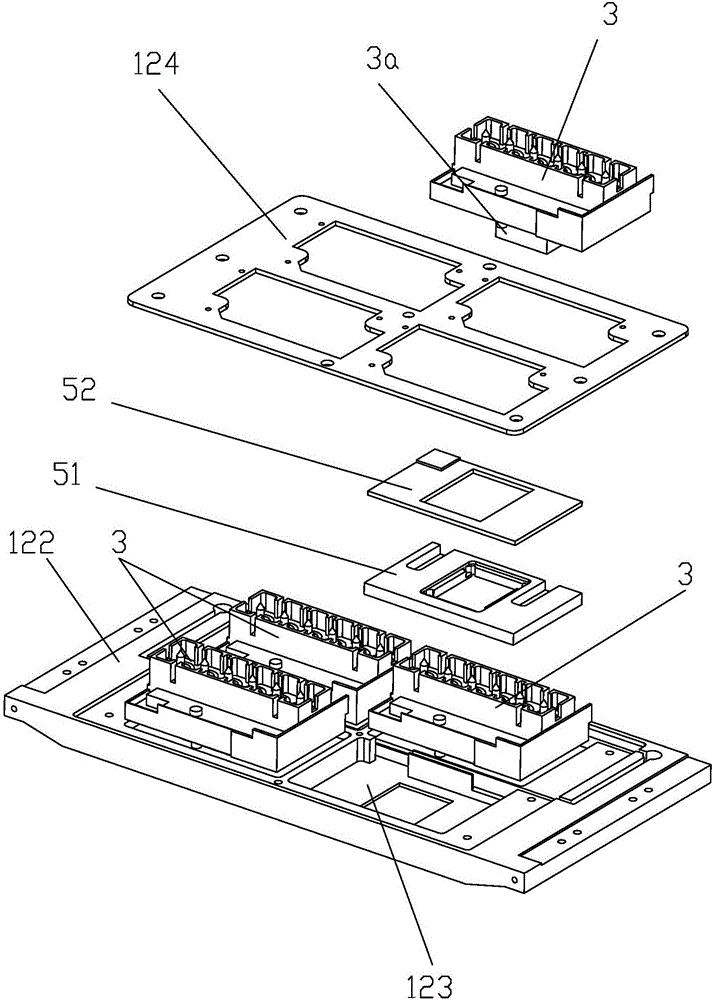

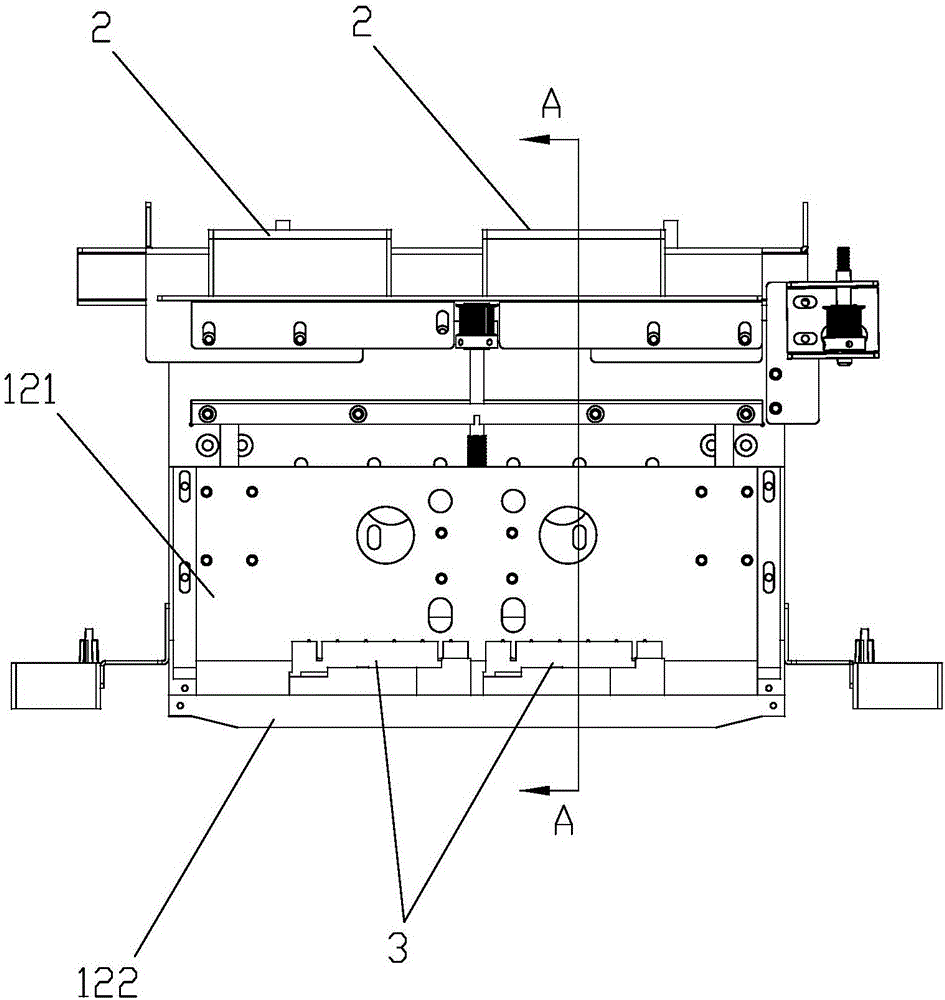

[0024] Such as Figure 1 to Figure 4 Shown, a kind of secondary heating device of the inkjet printing machine that adopts micro-piezoelectric printing head, comprises the inkjet support 1 that can move on the inkjet printing machine, and described inkjet support 1 comprises upper support 11 and with upper support 11 The connected lower bracket 12, the upper bracket 11 is provided with a plurality of ink cartridges 2, the lower bracket 12 is provided with a plurality of nozzles 3, and ink is arranged between the nozzles 3 and the corresponding ink cartridges 2 The ink cartridge 2 is connected with a first heating element 4 for heating the ink in it, and the lower bracket 12 is provided with a second heating element 5 for heating the ink ejection end 3a of the nozzle head 3 . The second heating is formed by the cooperation of the first heating element 4 and the second heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com