Fluorescent Lamp

A technology for fluorescent lamps and luminescent tubes, which is applied in the field of fluorescent lamps, and can solve the problems of decreased radiated light, peeling of fluorescent bodies, weak adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

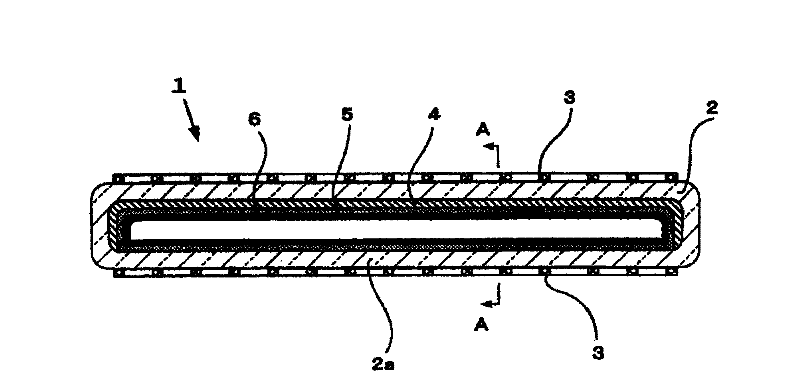

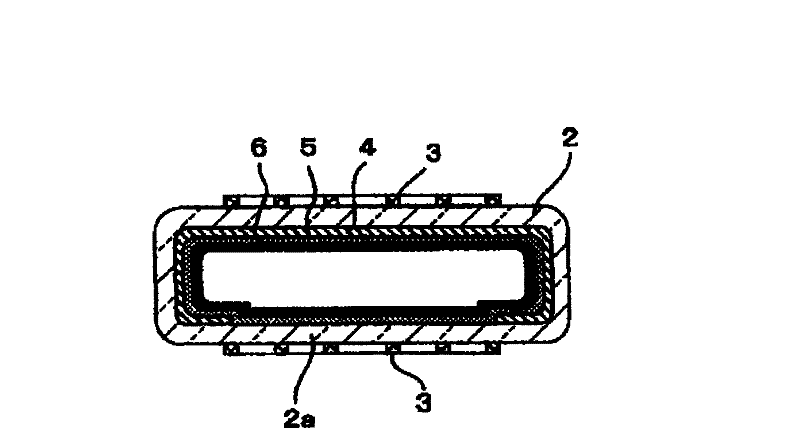

[0018] figure 1 is an axial sectional view of the present invention, figure 2 Is its A-A transverse sectional view.

[0019] exist figure 1 Among them, the phosphor 1 has an arc tube 2 made of quartz glass that is flat as a whole. The size of the luminous tube 2 is, for example, 14mm×42mm×650mm, and the thickness is 2mm.

[0020] A pair of opposite external electrodes 3 and 3 are provided on the upper and lower outer surfaces of the light emitting tube 2 .

[0021] An ultraviolet reflection layer 4 is provided on the inner surface of the arc tube 2 except for the light exit region 2 a where ultraviolet light is taken out from the arc tube 2 . In other words, the ultraviolet reflective layer 4 is formed except for a part of the inner surface of the arc tube 2 along the axial direction, and the region where the ultraviolet reflective layer 4 is not formed constitutes the light emitting region 2 a.

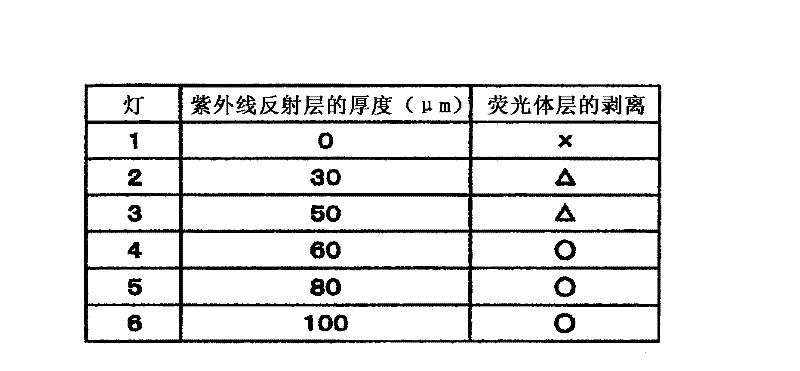

[0022] In addition, inside the ultraviolet reflection layer 4 , a glass la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com