Air tightness detection and wrist overturning system for gloves

An air-tightness detection and wrist-turning technology, applied in the directions of packaging automatic control, packaging, packaging protection, etc., can solve the problems of not being able to detect air leakage well, not having any fastening measures, and not being able to guarantee gaps, etc., and achieving a simple structure. , low cost, high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

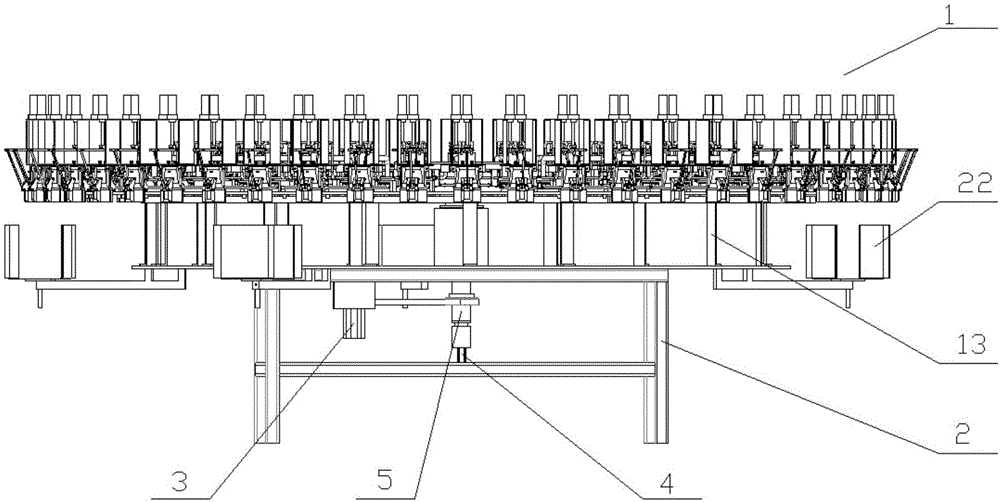

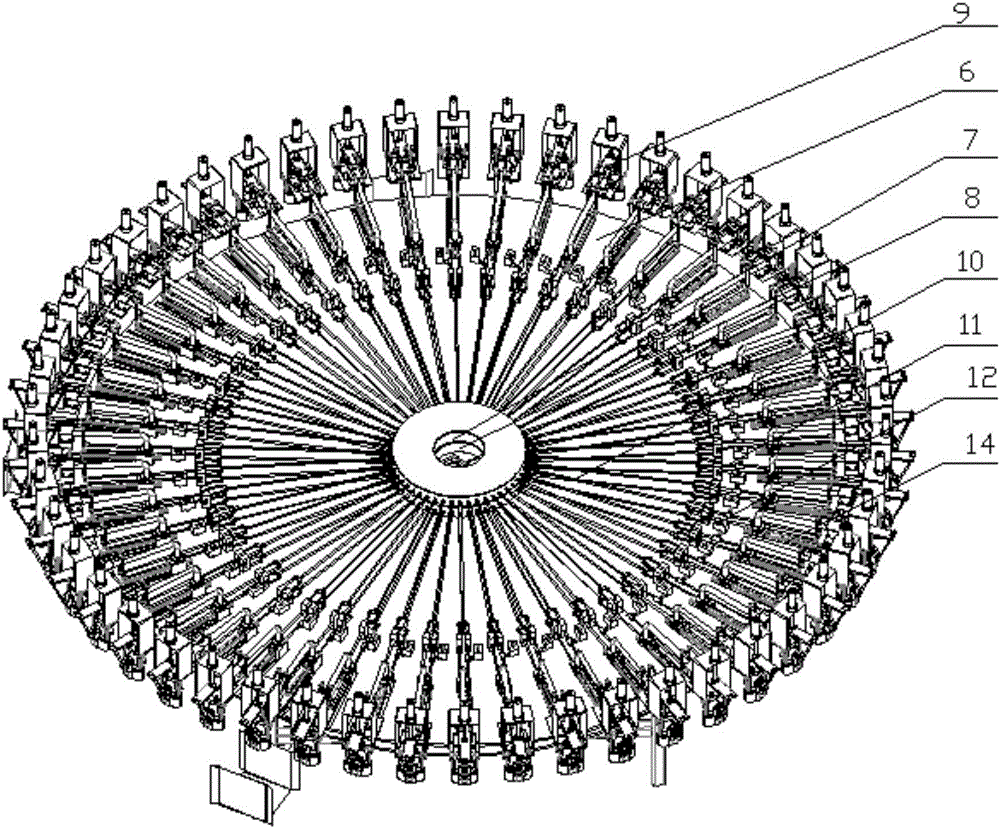

[0044] Such as figure 1 As shown, the glove air tightness detection and wrist turning system includes

[0045] Rack 2;

[0046] Servo motor 3: installed on the frame 2;

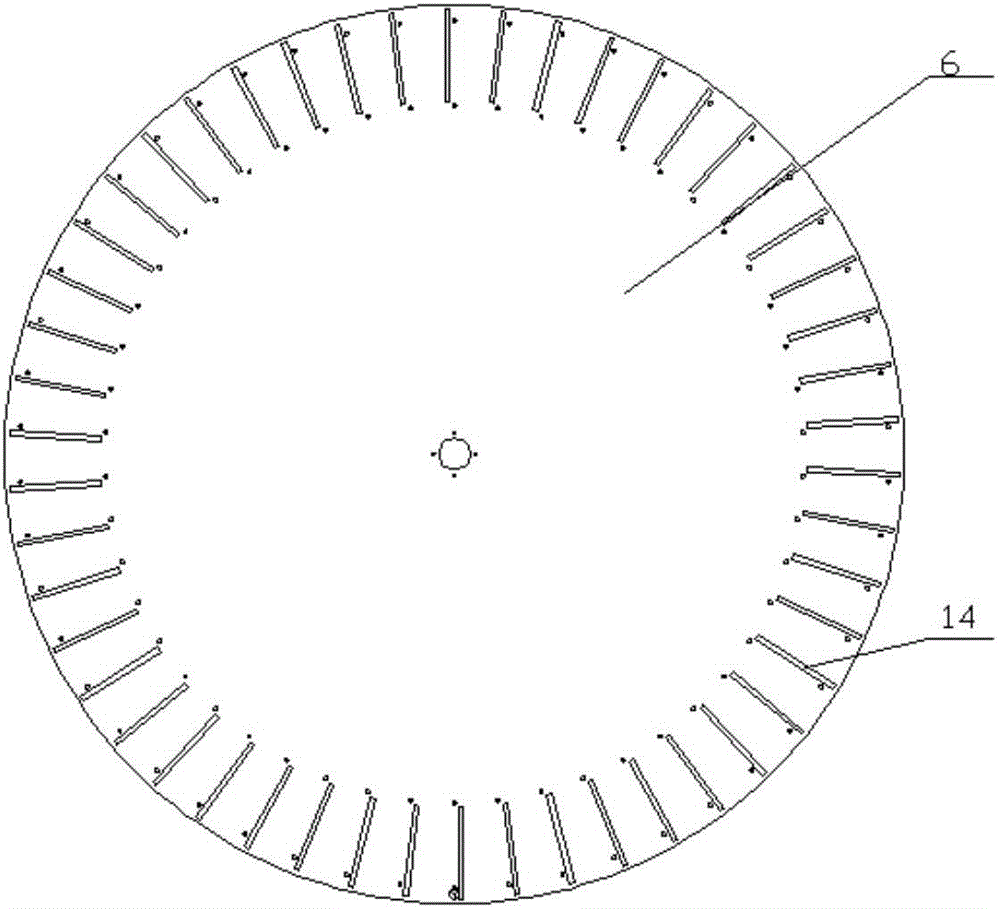

[0047] Track 13: AS Figure 4 As shown, there are protrusions 20 and more than three legs 21, the track 13 and the legs 21 are integrally structured, and the track 13 is fixed on the frame 2 through the legs 21;

[0048] Detection positions: at least 4 are evenly distributed at the bottom of the track;

[0049] Drive shaft 5: fixed on the frame 2 through bearings;

[0050] Pneumatic slip ring 4: installed on the lower end of the driving shaft 5;

[0051] Vacuum pump 23: connected to the gas-electric slip ring 4 through a pipeline;

[0052] Air compressor 24: connected to the gas-electric slip ring 4 through a pipeline;

[0053] Air tightness detection and wrist turning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com