Online optical fiber laser oxygen concentration monitoring and early warning system for inner floating roof light oil product tank

An oxygen concentration, light oil technology, applied in containers, packaging, transportation and packaging, etc., can solve the problems of high construction requirements, inconvenient maintenance, lax sealing rings, etc., so as to reduce the risk of lightning strikes and explosions. , the effect of high detection accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

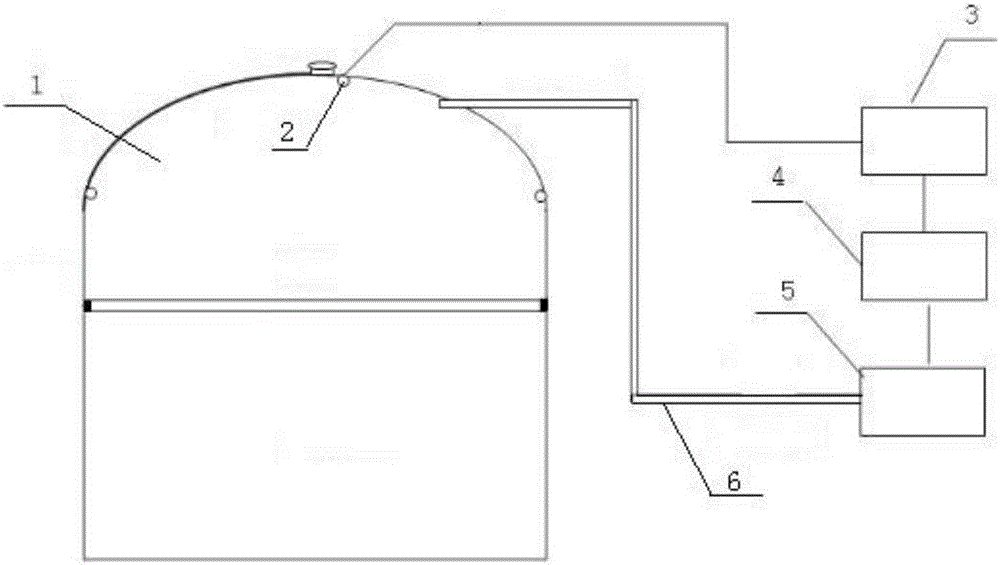

[0011] Such as figure 1 As shown, the structure of this embodiment includes an oxygen concentration sensor 2, an oxygen concentration analyzer 3, an oxygen-oil gas concentration explosion limit warning system 4, and an inert gas dilution system 5, and the oxygen concentration sensor is arranged on the inner floating top light oil product The inner side of the vault of the tank 1 is connected to the oxygen concentration analyzer 3 through a jumper, and the oxygen-oil gas concentration explosion limit warning system 4 is respectively connected to the oxygen concentration analyzer 3 and the inert gas dilution system 5, and the inert gas dilution system 5 The pipeline 6 communicates with the inside of the light oil tank 1, and the oxygen-oil gas concentration explosion limit warning system 4 is used for early warning of the oxygen limit concentration in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com