A kind of rubber composition and its preparation method and application

A rubber composition, butyl rubber technology, applied in tire parts, transportation and packaging, special tires, etc., can solve the problems of high cost of butyl wind tires, astonishing tire consumption, hindering development, etc., to achieve guaranteed performance, relieve environmental pressure, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

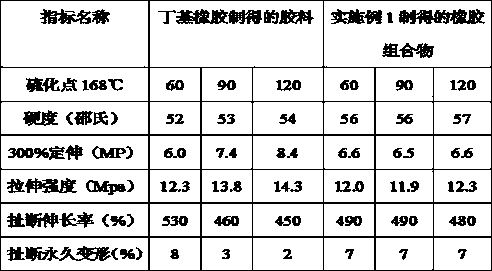

Examples

preparation example Construction

[0022] The preparation method of described rubber composition, comprises the following steps:

[0023] 1) One-stage mixing process: put butyl rubber and chlorobutyl reclaimed rubber into the F160 internal mixer, mix the rubber for 85~95s, operate for 20s, and rotate the rotor at 28~32 rpm; then lift the upper Stearic acid and high wear-resistant carbon black are added to the top bolt, the pressing time is 115~125s, and the operation time is 15s; the top bolt is lifted for 115~125s, and the operation time is 5s; 125s, operation time 5s; degumming 20s, degumming temperature 170~180℃; then on the open mill with a roller distance of 8mm and keeping the left and right sides consistent, turn over for no less than 6 times, and then cool down the next piece to obtain a section of kneading glue;

[0024] 2) Two-stage mixing process: Put 2 / 3 of the first-stage mixed rubber into the F160 internal mixer, the non-pressing time is 25~35s, and the operating time is 20s; then lift the bolt, ...

Embodiment 1

[0031] 1) One-stage mixing process: put 100 parts of butyl rubber and 86.64 parts of chlorinated butyl reclaimed rubber into the F160 internal mixer, mix the rubber for 90s, operate for 20s, and the rotor speed is 30 rpm; Add 1.29 parts of stearic acid and 60 parts of high wear-resistant carbon black to the top bolt. The pressing time is 120s, and the operation time is 15s; the top bolt is lifted up for 120s, and the operation time is 5s; The operation time is 5s; the glue removal is 20s, and the glue removal temperature is 178°C; then, on the open mill with a roller distance of 8mm and keeping the left and right sides consistent, turn over 6 times and then cool down the next piece to obtain a section of mixed rubber;

[0032] 2) Two-stage mixing process: put 2 / 3 of the first-stage rubber into the F160 internal mixer, the non-pressing time is 30s, and the operating time is 20s; then lift the bolt, and put the remaining 1 / 3 of the first-stage rubber into the F160 In the interna...

Embodiment 2

[0039]1) One-stage mixing process: put 100 parts of butyl rubber and 75 parts of chlorinated butyl reclaimed rubber into the F160 internal mixer, mix the rubber for 85s, operate for 20s, and rotate the rotor at 28 rpm; then lift the upper Add 1 part of stearic acid and 50 parts of high wear-resistant carbon black to the top bolt. The pressing time is 115s, and the operation time is 15s. Lift the top bolt and press for 115s, and the operation time is 5s. The operation time is 5s; the glue removal is 20s, and the glue removal temperature is 170°C; then, on the open mill with a roller distance of 8mm and keeping the left and right sides consistent, the next piece is cooled after turning 7 times, and a section of mixed rubber is obtained;

[0040] 2) Two-stage mixing process: put 2 / 3 of the first-stage rubber into the F160 internal mixer, the non-pressing time is 25s, and the operating time is 20s; then lift the bolt, and put the remaining 1 / 3 of the first-stage rubber into the F16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com