A rare-earth ore-alkali decomposition tubular reaction device and process

A tubular reaction device and alkali decomposition technology, which is applied in the field of rare earth mine alkali decomposition tubular reaction device, can solve the problems of low rare earth decomposition rate, difficult automatic control, and many transmission equipment, so as to avoid pipeline scarring, Ease of temperature control and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

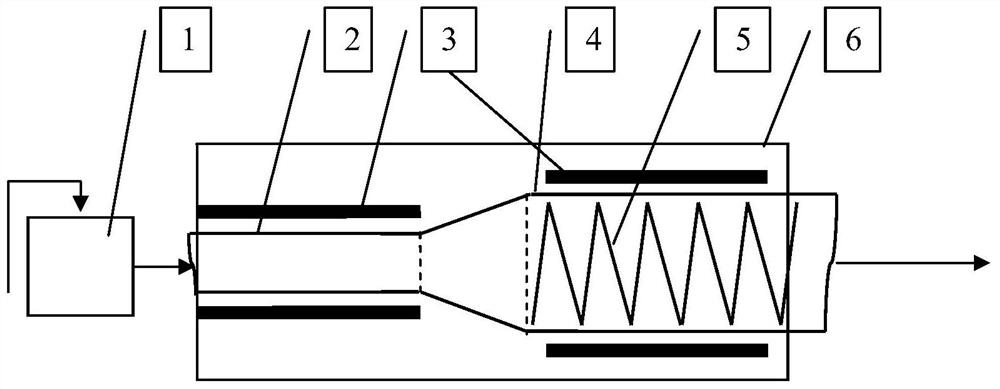

[0022] The present invention as figure 1 As shown, the prepared rare earth slurry is sent into the heating reaction inner tube 2 through the high-pressure diaphragm pump 1, and the slurry in the heating reaction inner tube 2 is heated by a far-infrared heater to 120°C. After the slurry is heated to the reaction temperature, it enters After 50 minutes in the heat preservation reaction inner tube 4, the solid-liquid separation is carried out. The flow velocity of the ore slurry in the heating reaction tube is 1.9m / s, and the flow rate of the tube in the heat preservation reaction is 1.4m / s. The pipeline is equipped with static spiral stirring, and the rare earth decomposition rate reaches 97.6%.

Embodiment 2

[0024] The present invention as figure 1 As shown, the prepared xenotime rare earth slurry is sent into the heating reaction inner tube 2 through the high-pressure diaphragm pump 1, and the slurry in the heating reaction inner tube 2 is heated by a far-infrared heater to 350°C, and the slurry is heated to the reaction After entering the heat preservation reaction inner tube 4 for 40 minutes, it will be transported for solid-liquid separation. The flow velocity of the ore slurry in the heating reaction tube is 1.4m / s, while that in the heat preservation reaction tube is 1.1m / s. The pipeline is equipped with static spiral stirring, and the rare earth decomposition rate reaches 97.9%.

Embodiment 3

[0026] The present invention as figure 1 As shown, the prepared Baotou mixed rare earth ore slurry is sent into the heating reaction inner tube 2 through the high-pressure diaphragm pump 1, and the slurry in the heating reaction inner tube 2 is heated by a far-infrared heater to 180°C, and the slurry is heated to After the reaction temperature, enter the heat preservation reaction inner tube 4 for 30 minutes and then transport the solid-liquid separation. The flow velocity of the slurry in the heating reaction tube is 1.6m / s, while the flow velocity of the tube in the heat preservation reaction is 1.3m / s, and the rare earth decomposition rate reaches 97.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com