Assembled polyurethane heat insulation wall body and production method thereof

A thermal insulation wall, polyurethane technology, applied in the direction of walls, building components, buildings, etc., can solve the problem that it is difficult to realize the overall airtightness of wallboards, the combination of wallboards, etc. Effect of improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

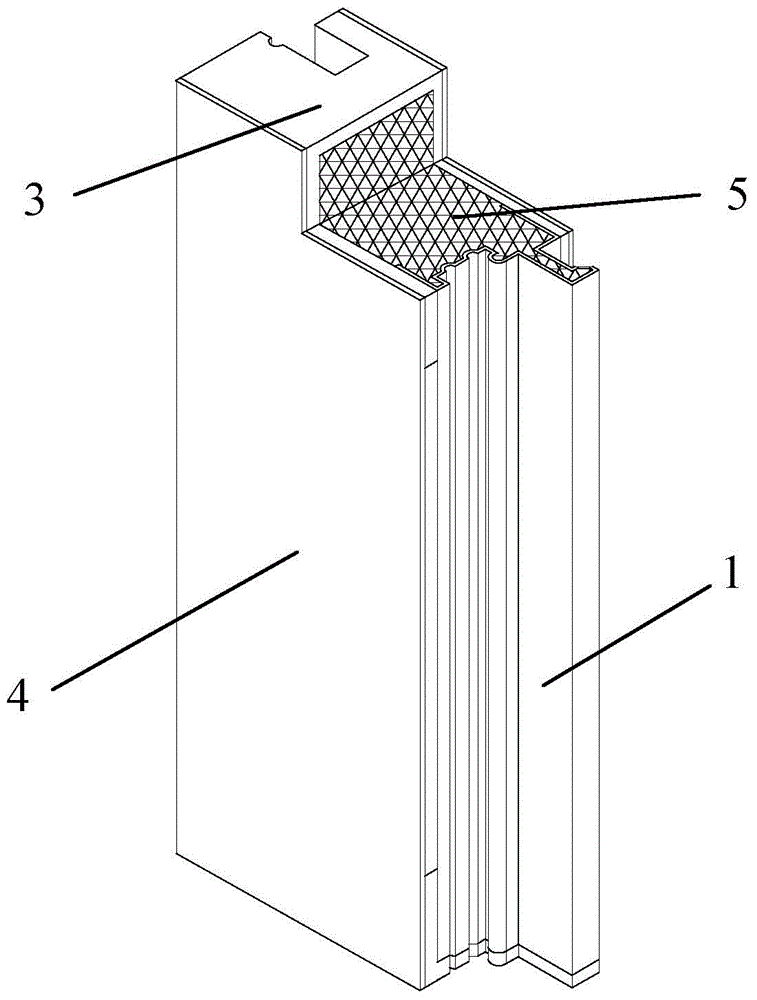

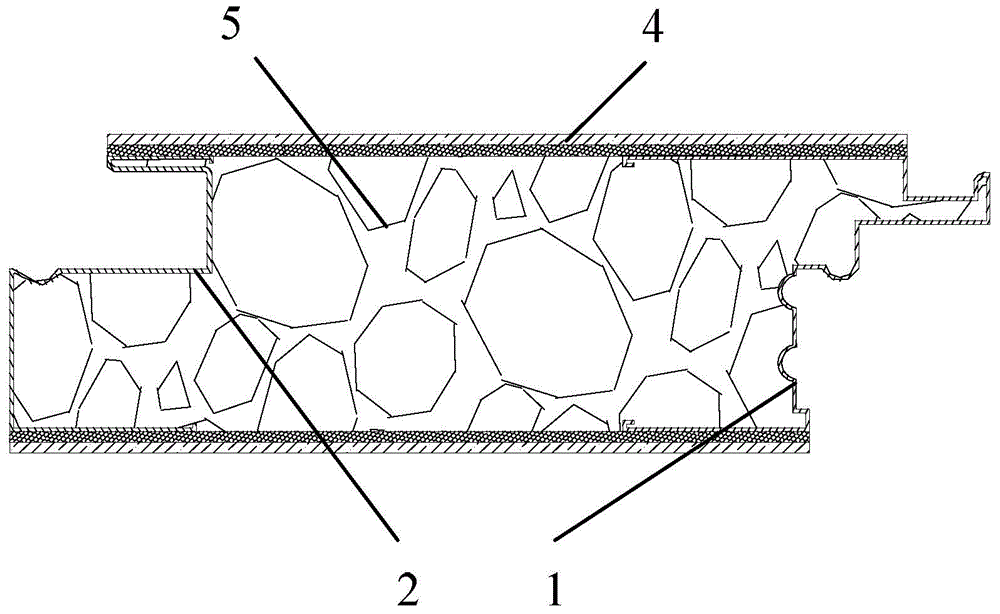

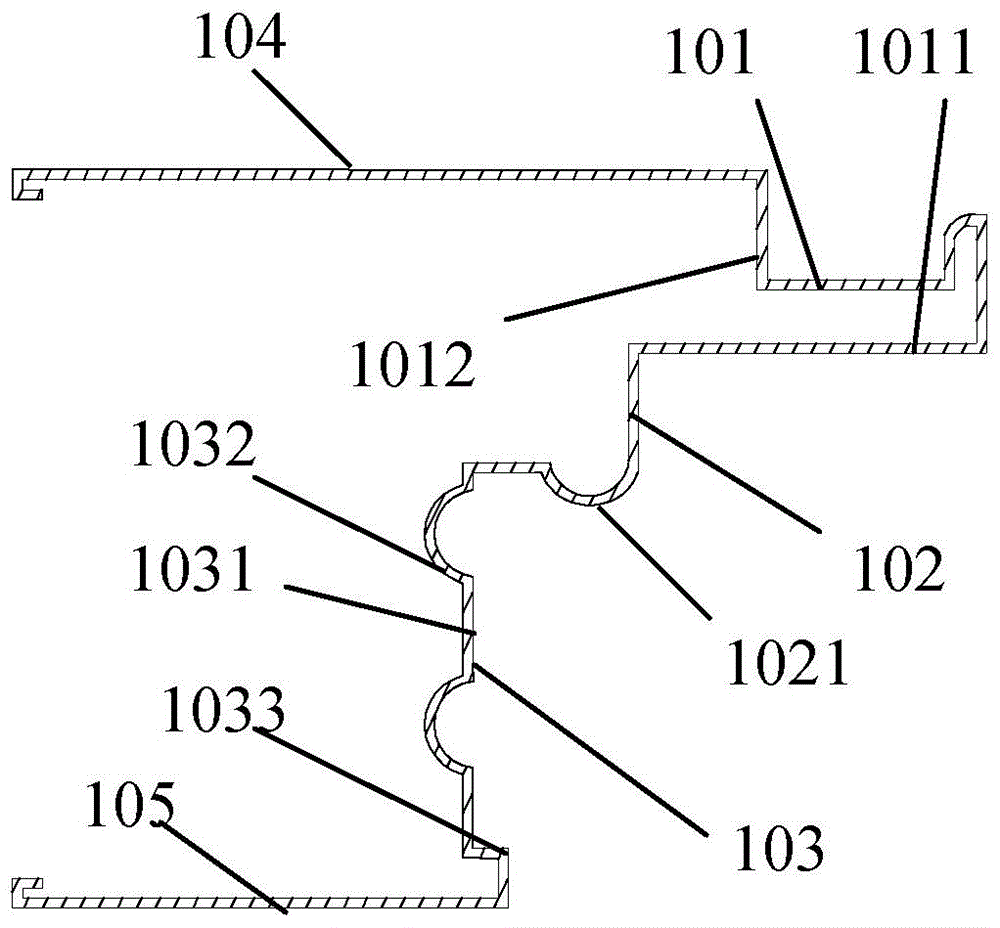

[0050] Such as figure 1 with figure 2 as shown, figure 1 It is a schematic diagram of the prefabricated polyurethane insulation wall, figure 2It is a cross-sectional schematic diagram of a prefabricated polyurethane insulation wall. An assembled polyurethane thermal insulation wall, comprising two support frames 3 , a first connecting piece 1 , a second connecting piece 2 , a wall panel 4 , and a polyurethane filling material 5 . The two support frames 3 are elongated profiles with a groove-shaped cross-section and high strength, including a bottom plate and two side plates. The side plates of the two support frames are arranged opposite to each other, and are arranged i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com