A masonry horizontal mortar joint controller and construction method

A controller and masonry technology, applied in construction, building structure, building material processing and other directions, can solve the problems of difficult control of horizontal ash joint thickness and saturation in construction, avoid the phenomenon of falling ash and ensure the quality of masonry , make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

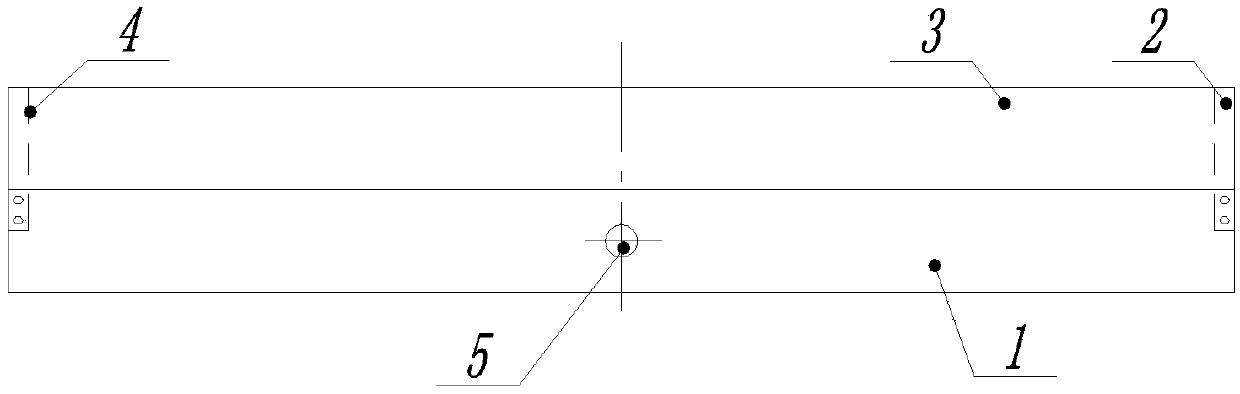

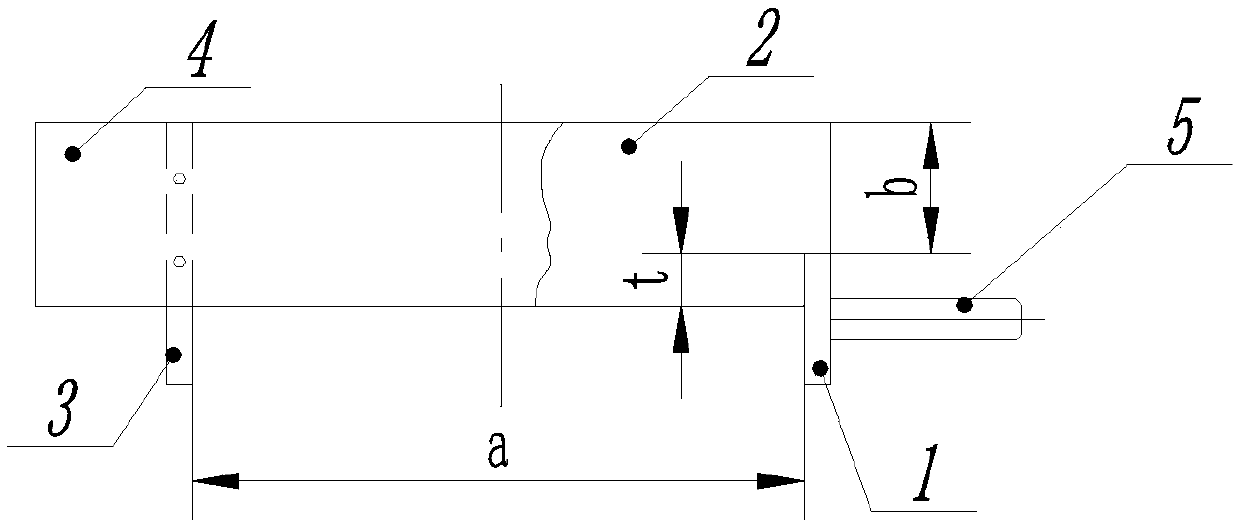

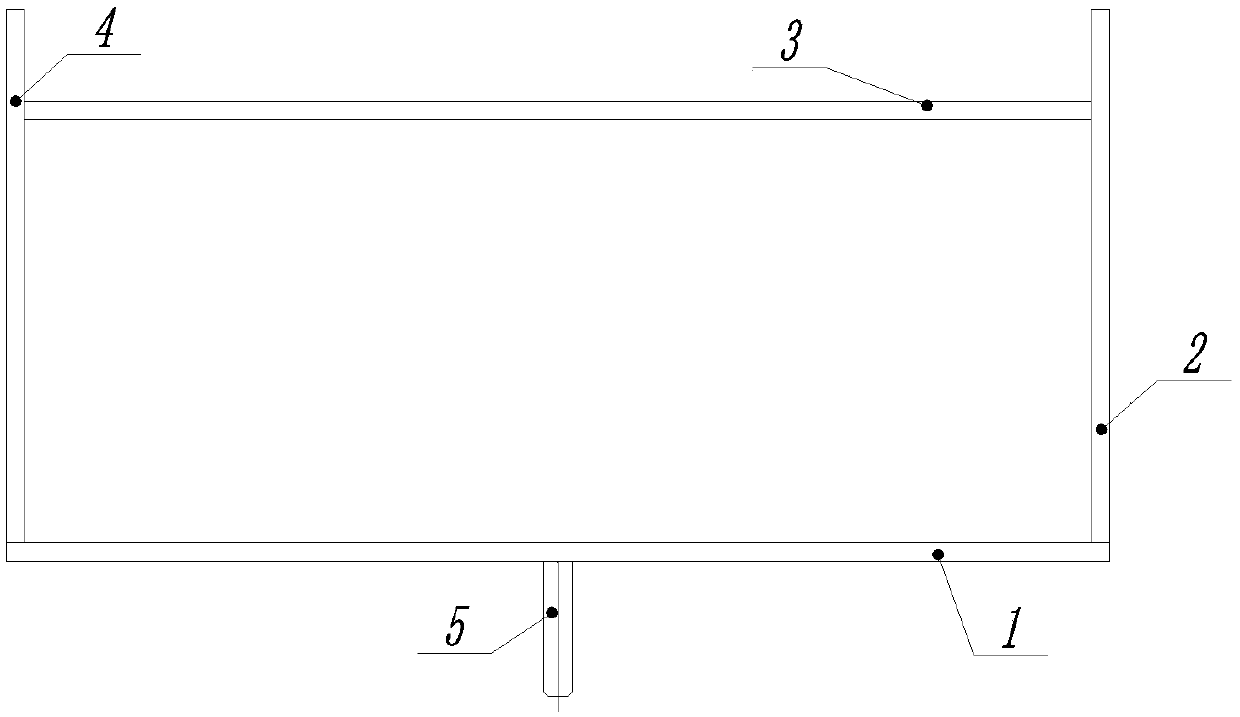

[0031] See Figure 1-Figure 3 , the present invention relates to a masonry horizontal mortar joint controller, comprising a front board 1, a rear board 3, a left board 4, a right board 2 and a handle 5, the front board 1, the left board 4, the right board 2 and the The rear plate 3, the left plate 4, and the right plate 2 are all fastened with screws to form a rectangular frame, and the handle 5 is arranged on the front plate 1.

[0032] The height difference b between the rear panel 3 and the front panel 1 = the thickness of the masonry body -0.8-1.5mm.

[0033] The height of the left plate 4 is the same as that of the right plate 2. When assembling with the front plate 1 and the rear plate 3, the lower ends of the front plate 1 and the rear plate 3 are flush, and the upper ends of the left plate 4 and the right plate 2 are aligned with the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com