Spiral PDC drill bit with detachable cutting teeth

A technology of cutting teeth and drill bits, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc., to achieve the effect of reducing difficulties and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, illustrate the new structure drill bit that the present invention proposes, feature, effect, describe in detail as follows;

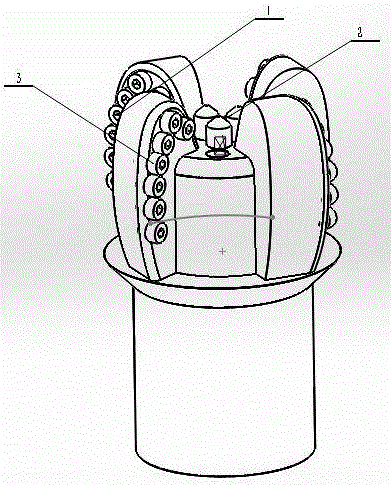

[0020] The PDC drill bit mainly includes an integrated cutting tooth 3 , a tapered cutter 2 and a cutter wing 1 .

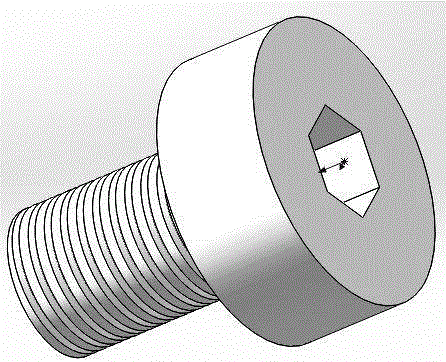

[0021] The blade 1 and the bit body are integrated, and there is a threaded hole on the blade 1. The integrated cutting tooth 1 is threadedly connected with the threaded hole, which makes the integrated cutting tooth 1 can be disassembled from the bit body separately. In the process of drilling coal and rock, because the drill bit drills into the coal seam through shearing and drilling pressure to achieve drilling into the coal seam, it is easy to be worn or damaged. When this happens, the damaged integrated The cutting teeth 3 are replaced, so that the drill bit has flexibility, and the service life and working efficiency of the drill bit are improved to a large extent.

[0022] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com